Cummins Inc., established in 1919 in Columbus, Indiana, has grown to become one of the leading manufacturers of diesel and natural gas engines in the world. Known primarily for robust, reliable engines, Cummins has also carved out a significant niche in the power generation market. Cummins generators are renowned for their durability and efficiency, making them a preferred choice in various sectors, including construction, healthcare, and data centers, where uninterrupted power is critical.

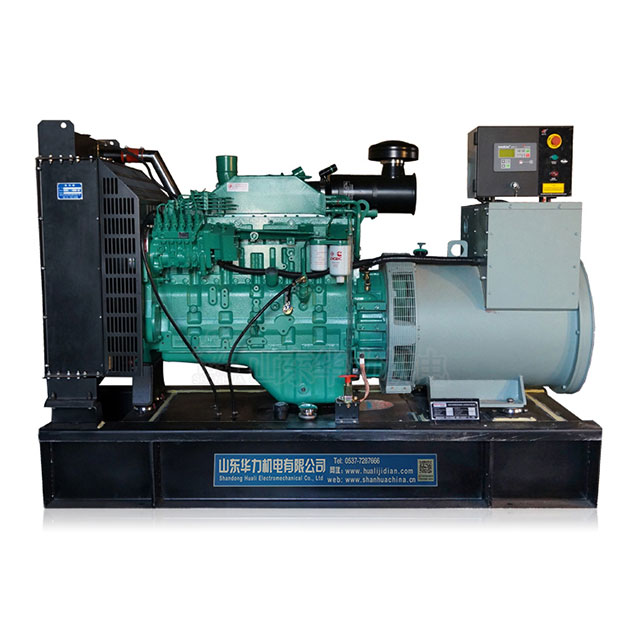

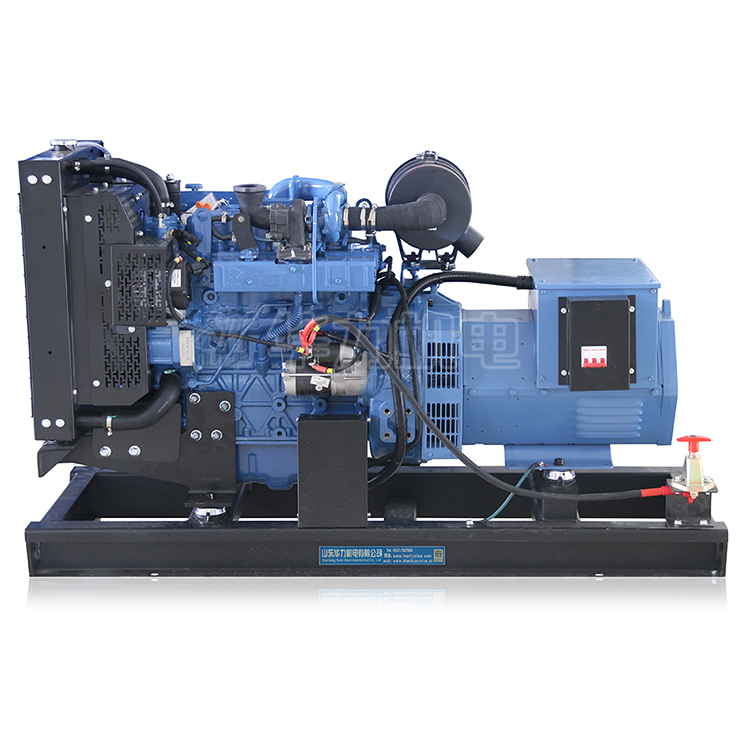

Cummins backup generators are designed to provide reliable, quick-starting backup power during utility failures or major emergencies. Ranging from small, portable units ideal for home use to large systems capable of powering industrial facilities, Cummins offers a comprehensive range of generator solutions. These generators are known for their high-performance levels, which include features such as advanced sound attenuation and environmental compliance. The product line also integrates seamlessly with existing home or business power systems, offering an easy transition from primary to backup power with minimal interruption.

Cummins’ commitment to innovation is evident in their continuous enhancement of generator capabilities, particularly in terms of fuel efficiency and emission reductions, positioning Cummins backup generators as a top-tier choice for those seeking dependable emergency power solutions.

Why Choose a Cummins Backup Generator?

Cummins backup generators are engineered to provide dependable power when it’s most needed. These generators are equipped with advanced technologies that ensure rapid start-up times and efficient operation during power outages. The reliability of Cummins generators is backed by rigorous testing under extreme conditions to ensure they can withstand the most challenging environments.

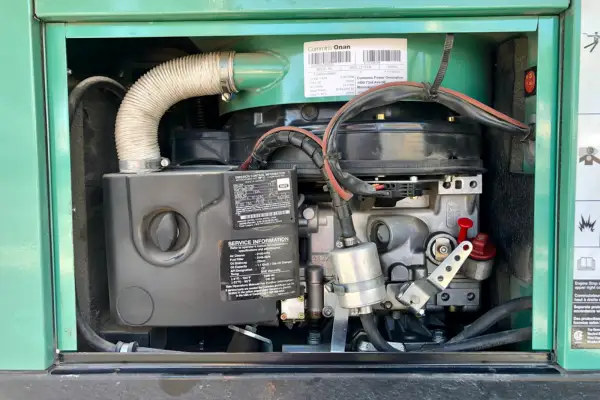

A notable feature is the robust engine design, which utilizes Cummins’ deep expertise in engine production to guarantee long operational life with minimal downtime. This is critical for settings where power is essential, such as hospitals and data centers. The generators are also designed to meet stringent emissions standards, making them suitable for use in sensitive environments.

Comparison with Other Backup Power Options in the Market

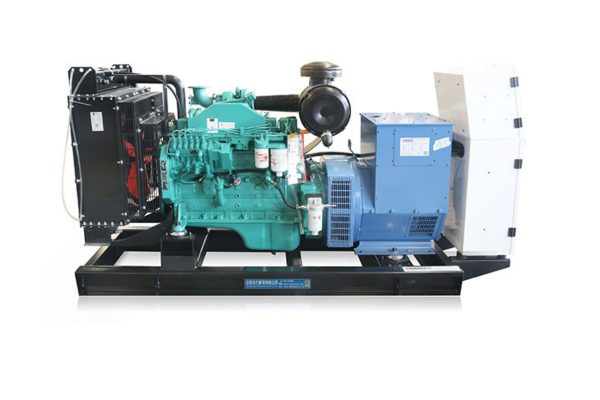

When compared to other market options, such as generators powered by gasoline, propane, or natural gas, Cummins backup generators stand out primarily for their diesel-powered efficiency and robustness. Diesel engines are generally more durable and provide more power per gallon of fuel than their gasoline counterparts. This translates into longer run times and lower operational costs over the generator’s lifespan.

Furthermore, Cummins generators are praised for their quiet operation and compact design, making them less intrusive and more adaptable to a variety of spaces. The integration of state-of-the-art control systems allows for seamless operation, with digital monitoring capabilities that other brands often offer only at a premium.

In essence, choosing a Cummins backup generator means investing in a system known for its reliability and performance, ensuring peace of mind during emergencies. The comparison with other brands often highlights Cummins’ superior technology, customer service, and comprehensive warranty coverage, making it a leader in the field of backup power solutions.

Key Features of Cummins Backup Generators

Cummins backup generators come in a range of models, each designed to meet specific power needs and operational environments. From the QD Series designed for quiet diesel power in residential areas to the heavy-duty QSK95 Series that can serve large facilities and critical systems, Cummins offers generators that suit both small homes and major industrial operations.

The technical specifications of these generators are particularly impressive. For instance, the smaller models like the QuietConnect Series feature power ratings from 22 kW to 60 kW, ideal for most homes and small businesses. These models are engineered for extremely quiet operation and are EPA Tier 4 compliant, demonstrating Cummins’ commitment to environmental sustainability.

On the other end, the high-capacity models, like the QSK95, deliver up to 3,500 kW of power and are commonly used in hospitals, data centers, and municipal infrastructure projects where failure is not an option. These generators are equipped with high-performance engines that provide efficient power delivery and feature advanced control systems for easy monitoring and management.

Innovations in Fuel Efficiency and Emissions Reduction

Cummins has long been at the forefront of innovation in fuel efficiency and emissions control in the generator industry. The latest models of Cummins backup generators are equipped with technology that optimizes fuel consumption and reduces emissions to meet global environmental standards, including the stringent EPA Tier 4 regulations for diesel engines.

These innovations include advanced combustion control technology, selective catalytic reduction (SCR), and diesel particulate filters (DPF) that significantly lower the amount of harmful emissions released into the atmosphere. Furthermore, Cummins continuously works on enhancing the fuel economy of their generators, which not only reduces operational costs but also minimizes the environmental footprint of their products.

By incorporating these cutting-edge technologies, Cummins backup generators offer superior performance, ensuring that users receive reliable power while also contributing to a greener planet. This focus on fuel efficiency and emissions reduction demonstrates Cummins’ dedication to innovation and environmental stewardship, making their generators some of the most advanced and sustainable options available on the market.

Installation Guidelines for Cummins Backup Generators

Installing a Cummins backup generator involves several crucial steps to ensure safety, compliance with local regulations, and optimal performance. The process begins with selecting the appropriate generator model based on the power needs and the physical constraints of the installation site.

- Site Preparation: Choose a location for the generator that is stable, well-ventilated, and protected from the elements. It should be away from windows and doors to prevent exhaust gases from entering the building. The site should also allow easy access for maintenance.

- Foundation Setup: A concrete pad is recommended as a base for the generator to ensure stability and reduce vibration. The dimensions of the pad should adequately support the weight and size of the generator.

- Electrical and Fuel Connections: This step should be handled by a professional. It involves connecting the generator to the fuel supply—diesel, natural gas, or propane—and integrating it with the existing electrical system. This includes installing a transfer switch to safely engage the generator when the main power fails without back-feeding the grid.

- Compliance and Safety Checks: Once installed, the system should be inspected by a licensed electrician or a representative from the local power authority to ensure that the installation complies with all local codes and regulations.

- Initial Testing: After installation, the generator should be tested under load conditions to ensure it operates as expected. This test will confirm that the generator can handle the expected power load and that all connections are secure and functioning correctly.

Tips on Choosing the Right Location and Preparing Your Site

Selecting the right location for your Cummins backup generator is critical for effective operation and longevity. Consider the following:

- Accessibility: Ensure that the installation site is easily accessible for maintenance and fuel delivery.

- Safety: The generator should be located away from flood zones and areas susceptible to debris and flooding.

- Noise Considerations: Keep in mind local noise ordinances. Cummins generators are designed to operate quietly, but strategic placement can further reduce noise impact on the surrounding areas.

- Ventilation: Proper ventilation is crucial for preventing overheating and allowing the engine to operate efficiently.

Proper installation of a Cummins backup generator is essential for reliable operation. It ensures that when power interruptions occur, your generator will function seamlessly, providing a smooth transition from utility power to generator power and safeguarding your premises against unexpected blackouts.

Maintenance and Care for Your Cummins Backup Generator

Maintaining your Cummins backup generator is crucial for ensuring its longevity and reliability, especially during critical times when you need emergency power. Here’s a streamlined approach to routine maintenance:

- Regular Inspections: Conduct weekly inspections to check for any visible issues such as leaks or corrosion. Ensure that all connections are tight and the unit is clean and free of debris.

- Oil and Filter Changes: Like any diesel engine, your Cummins generator requires regular oil changes. Follow the manufacturer’s guidelines, typically after every 100 hours of operation or annually, whichever comes first. Similarly, replace air and fuel filters at the same intervals to maintain fuel efficiency and engine performance.

- Cooling System Maintenance: Check the coolant level before each operation and top it off if necessary. Annually, flush the system and replace the coolant to prevent overheating and engine damage.

- Battery Care: The battery should be checked regularly for proper charge and clean terminals. Most generator failures are due to battery issues, so keeping it in good condition is essential.

- Exercise the Generator: Running the generator on a monthly basis helps to keep all mechanical parts lubricated and prevents carbon build-up. This also ensures the generator starts up easily when needed.

Common Troubleshooting Issues and How to Solve Them

Even with meticulous maintenance, you may encounter some common issues with Cummins backup generators. Here are a few troubleshooting tips:

- Failure to Start: Check the battery first, as it’s the most common cause of startup failure. Ensure it’s fully charged and terminals are clean. Next, check the fuel supply and ensure there are no clogs in the fuel filter.

- Irregular Running: If the generator runs unevenly or stops suddenly, check the air intake and exhaust for blockages. Also, verify that the fuel is clean; water or debris in the fuel can cause operational issues.

- Excessive Noise or Vibration: Unusual noises or vibrations might be a sign of loose parts. Check and secure all bolts and connections. Also, inspect the mounting pad because a generator that’s not level can vibrate excessively.

- Electrical Output Issues: If the generator isn’t producing the correct voltage, consult a professional. This could be due to a serious issue within the alternator or electrical system that might require professional calibration or repairs.

Regular maintenance not only extends the lifespan of your Cummins backup generator but also ensures it performs optimally when you need it most. By adhering to these guidelines and addressing common issues promptly, you can rely on your Cummins generator for secure and efficient backup power for many years.

Real-World Applications of Cummins Backup Generators

Cummins backup generators have a proven track record of reliability and effectiveness across various emergency scenarios. One notable case involved a regional hospital during a prolonged blackout caused by a severe hurricane. The Cummins backup generator system kicked in moments after the power outage began, maintaining critical systems such as life-support machines and hospital lighting. This not only ensured the safety and well-being of patients but also allowed medical staff to continue their work unhindered during the crisis.

Another instance saw a Cummins backup generator at a data center prevent data loss and service interruptions during an unexpected power failure. The generator provided uninterrupted power supply, demonstrating its capacity to handle high-demand situations and protect sensitive information crucial for business operations.

Testimonials from Businesses and Households

The reliability and efficiency of Cummins backup generators have garnered positive feedback from a wide range of users, from residential to commercial clients. Homeowners often highlight how these generators provide peace of mind, especially those living in areas prone to natural disasters where power outages are common. They commend Cummins for their generator’s quiet operation and low maintenance requirements.

Business owners, particularly those from the healthcare and IT sectors, emphasize the importance of having a reliable power source that can support critical operations. Many testimonials point to instances where Cummins generators have successfully prevented operational disruptions and financial losses during emergencies.

The repeated success stories across different applications firmly establish Cummins backup generators as a dependable solution for emergency power needs. They not only ensure continuity in businesses and safety in homes but also stand out as a leader in the backup power industry, providing effective solutions tailored to a wide range of energy needs.

Choosing the Right Cummins Model for Your Needs

Choosing the right Cummins backup generator involves a careful evaluation of your specific power requirements and budget constraints. Here’s how to make an informed decision:

- Assess Your Power Needs: Calculate the total wattage of the critical appliances and systems you need to run during an outage. Include essentials like refrigerators, heating systems, medical equipment, and in some cases, entire business operations. Cummins offers a range of models from residential to industrial scale, so understanding your power needs will guide your choice.

- Consider the Installation Environment: Think about the physical space where the generator will be installed. Smaller properties might require more compact solutions, whereas larger commercial spaces can accommodate bigger units. Environmental conditions such as temperature and elevation can also influence generator performance, so choose a model that matches your geographical specifics.

- Budget Planning: Backup generators are a significant investment. While budgeting, consider not only the upfront cost but also long-term operating and maintenance expenses. Diesel generators, like those from Cummins, often offer lower running costs compared to gasoline generators, which can be a critical factor in your decision-making process.

Factors to Consider When Purchasing a Backup Generator

When purchasing a Cummins backup generator, several factors should be taken into account to ensure you select the best model for your needs:

- Fuel Type: Diesel, natural gas, and propane are common fuel options, each with its advantages. Diesel engines are typically more durable and efficient but check fuel availability and storage regulations in your area.

- Noise Levels: Especially important for residential areas, Cummins generators are engineered to operate quietly. Still, consider the decibel ratings to ensure compliance with local noise ordinances.

- Maintenance Requirements: Understand the maintenance schedule for the generator you choose. Cummins is known for low maintenance costs, but regular service is vital for optimal performance and longevity.

- Warranty and Support: Check the warranty offered with the generator. Cummins’ robust support network can be a decisive factor, offering peace of mind through comprehensive service agreements and customer support.

Selecting the right Cummins backup generator involves balancing power needs with operational logistics and cost considerations. By taking the time to thoroughly assess these factors, you can ensure that your investment provides reliable power backup tailored to your specific requirements.

FAQs: Common Questions About Cummins Backup Generators

What is the typical lifespan of a Cummins backup generator? The lifespan of a Cummins backup generator can vary based on usage and maintenance but typically ranges from 15 to 30 years. Regular maintenance and proper installation are key factors that extend the operational life of these generators.

How often should I perform maintenance on my Cummins generator? Maintenance frequency for Cummins backup generators depends on the model and the operating conditions, but general guidelines recommend checking essential components like oil, filters, and batteries at least twice a year. For precise schedules, refer to the user manual specific to your generator model.

Can Cummins generators automatically start during a power outage? Yes, most Cummins backup generators are equipped with automatic transfer switches that detect power losses and start the generator automatically, ensuring continuous power without manual intervention.

What size generator do I need for my home or business? The size of the generator needed depends on your total power usage during an outage. Cummins offers a range of models from small units suitable for basic home needs to large systems designed for industrial applications. Calculating your peak power usage or consulting with a professional can help determine the appropriate size.

Are Cummins generators noisy? Cummins backup generators are designed with noise reduction technologies, making them among the quieter options available in the market. Specific noise levels can vary by model, but all are engineered to minimize disruption.

Where should I install my Cummins generator? It’s recommended to install your Cummins backup generator in a well-ventilated area, clear of obstructions and protected from extreme weather conditions. Local regulations may dictate specific installation requirements, so it’s advisable to consult with a professional installer or local authorities.

References

Cummins Home Generator Solutions – This page offers insights into the whole house generators by Cummins, including sizing, costs, and installation details. It emphasizes the reliability and quiet operation of Cummins generators, ideal for home standby power needs.

Cummins Generator Sets | Fully Integrated Power – This resource highlights the range of Cummins generator sets, discussing their efficiency, quality, reliability, and performance. It covers various fuel types including diesel and natural gas, tailored to meet diverse power needs.

QuietConnect™ Series | Home Generators | Cummins – This page focuses on the QuietConnect™ series, known for its low noise levels and efficient operation, making it suitable for residential use. It provides details about the series’ features and the benefits of installing these generators at home.

Cummins Power Generation | Generators and Power Systems – It offers a comprehensive look at Cummins’ capabilities in providing integrated power systems for various industries, highlighting their global support network and advanced technology solutions.

Genuine Cummins Parts – For those looking for parts and services for Cummins generators, this is the official source for genuine Cummins parts, ensuring your generator maintains peak performance.