Cummins Inc., renowned for its robust and efficient power solutions, has carved a niche in the realm of Cummins commercial generators. Known for their durability and reliability, Cummins generators are a cornerstone in the commercial sector, where power continuity is critical. Tom Linebarger, Chairman and CEO of Cummins Inc., has often emphasized the importance of dependable power solutions, stating, “Our commitment to building dependable systems reflects our vision for leading in global power solutions.”

For businesses, the continuity of operations hinges significantly on reliable power sources. Power outages can lead to operational disruptions, financial losses, and safety risks. Cummins generators are engineered to provide a steadfast power supply, ensuring that enterprises remain operational even during unplanned power interruptions. This reliability is not just a matter of convenience but a critical component of business continuity planning.

As we delve deeper into the specific features and advantages of choosing a Cummins commercial generator for your business, it becomes clear that their reputation is built on a foundation of engineering excellence and customer-focused innovations. Whether you’re operating in manufacturing, healthcare, or data center sectors, Cummins offers a tailored solution that aligns seamlessly with your enterprise’s power needs.

Understanding Generator Specifications

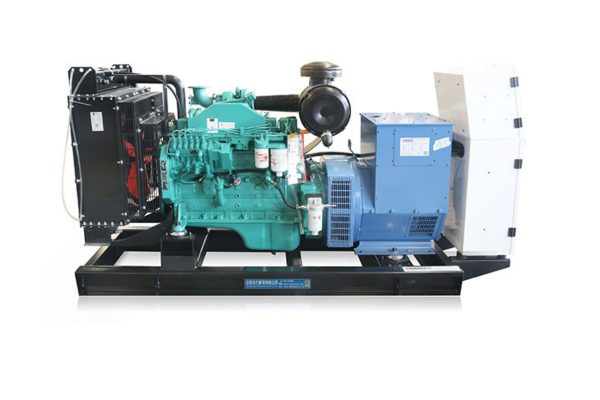

When selecting a Cummins commercial generator, it is crucial to understand the specifications that align with your business needs. Key specifications include power output, fuel type, and efficiency—each plays a pivotal role in ensuring that your generator can handle the demands of your enterprise efficiently and economically.

Power Output: The power output, measured in kilowatts (kW) or kilovolt-amperes (kVA), determines the generator’s capability to handle the load of your enterprise. A Cummins spokesperson once noted, “Selecting a generator with the right power output is crucial; too little power and you risk overloading the generator, too much and you waste money on unused potential.”

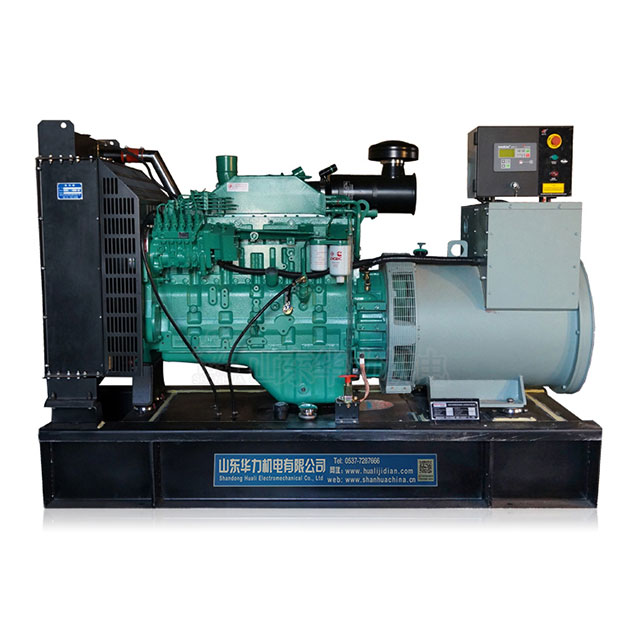

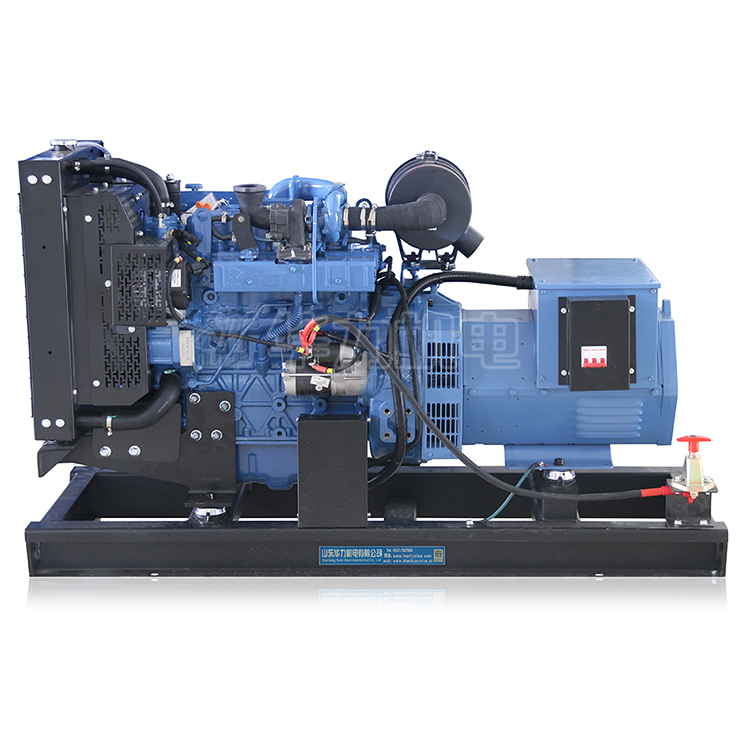

Fuel Type: Cummins offers generators that run on various fuels including diesel, natural gas, and hybrid options. Each fuel type has its benefits, depending on availability, cost, and environmental impact. For instance, diesel generators are known for their reliability and durability, making them suitable for environments requiring robust power solutions.

Efficiency: Efficiency relates to how effectively the generator converts fuel into electricity. A higher efficiency rating not only ensures lower operational costs but also reduces emissions, aligning with sustainability goals. Cummins integrates cutting-edge technology to enhance the efficiency of its generators, reducing the overall carbon footprint and operational costs.

Understanding these specifications is not just about reading a datasheet; it involves comprehending how each specification impacts the overall performance and cost-effectiveness of your setup. As advised by a leading engineer at Cummins, “Matching generator specifications to your business needs not only optimizes performance but also minimizes unnecessary expenditures on fuel and maintenance.”

Assessing Your Power Needs

Determining your enterprise’s power requirements is a fundamental step in selecting the right Cummins commercial generator. To ensure you choose a generator that fits your business’s needs without oversizing and incurring unnecessary costs, follow these guidelines:

- Calculate Total Power Consumption: Start by listing all the equipment and systems that will require power during an outage. This includes everything from lights and computers to heavy machinery and HVAC systems. Each piece of equipment will have a power rating, typically found on a nameplate or in the user manual, which you can sum up to get a total power requirement.

- Consider Redundancy Needs: For critical systems, redundancy might be necessary. This means having backup power for essential components like servers or cooling systems to ensure they remain operational even if one power source fails. This redundancy can be vital for industries like healthcare or data centers, where uninterrupted power is crucial.

- Plan for Future Expansion: It’s not just about what your power needs are today but also what they might be in the future. As your business grows, so too will your power requirements. Planning for future expansion can prevent the need for purchasing an additional generator later on, which can be more costly and disruptive.

- Understand Peak Usage: Some businesses, like those in manufacturing, may have peak usage times when power demand spikes. It’s important to understand these patterns as they will affect the type of generator you choose. As a Cummins engineer might suggest, “Considering your peak power usage ensures that the generator won’t be overstressed during critical times.”

- Consult with Professionals: Bringing in a professional to conduct an energy audit can provide a more accurate assessment of your power needs. They can help identify not just how much power you use, but when and where you use it, offering insights that can optimize both generator performance and fuel efficiency.

By thoroughly assessing your power needs, you ensure that the Cummins commercial generator you select not only meets your current demands but is also a viable long-term solution capable of scaling with your business. This strategic approach not only saves money in the long term but also bolsters your enterprise’s resilience against power disruptions.

In the next section, we’ll delve into the fuel options and efficiency considerations for Cummins commercial generators, which will further refine your selection process to ensure optimal performance and cost-effectiveness.

Fuel Options and Efficiency

Selecting the appropriate fuel type for a Cummins commercial generator is a critical decision that impacts both operational efficiency and cost-effectiveness. Cummins offers a range of fuel options, including diesel, natural gas, and hybrid models, each with distinct advantages and considerations:

- Diesel Generators: Diesel is often favored for its energy density and reliability, making it ideal for environments requiring robust, long-lasting power solutions. Diesel engines are known for their high torque and durability under harsh operational conditions. However, they may also come with higher emissions compared to natural gas, although modern Cummins diesel generators are designed to meet stringent environmental standards.

- Natural Gas Generators: These generators are celebrated for their cleaner burning compared to diesel, resulting in lower emissions of particulates and nitrogen oxides. Natural gas can be a cost-effective solution due to lower fuel prices in many regions and the ongoing push towards greener energy solutions. However, the availability of natural gas infrastructure can be a limiting factor.

- Hybrid Models: Hybrid generators combine diesel and electric power, potentially offering the best of both worlds: the reliability of diesel and the reduced emissions of electric operation. These models are particularly effective in applications where noise and emissions are a concern but where diesel is necessary for heavy-duty performance.

Efficiency Considerations:

- Fuel Efficiency: It’s crucial to consider the fuel efficiency of each type of generator. More efficient units reduce operating costs over time, which can significantly impact the total cost of ownership. Cummins invests heavily in technology to enhance the fuel efficiency of its generators, as noted by a leading Cummins product engineer, “Our focus on innovation extends to maximizing the fuel efficiency of our generators, ensuring more power with less fuel consumption.”

- Operational Costs: These costs include not only fuel but also maintenance and potential downtime. Diesel generators, for instance, typically have higher maintenance costs but may offer lower fuel costs depending on local diesel prices.

- Environmental Impact: Choosing a generator with lower emissions is not only better for the environment but can also be crucial for compliance with local and international environmental regulations. Cummins offers technologies that reduce emissions, aligning with global efforts to mitigate environmental impact.

In the upcoming section, we will explore the practical aspects of installing these generators, focusing on space requirements and whether to opt for professional installation or a do-it-yourself approach. This information will further assist in ensuring that your Cummins commercial generator is not only efficient but also well-integrated into your business operations.

Installation Considerations

Installing a Cummins commercial generator involves several critical considerations that ensure the unit operates efficiently and safely within your business environment. These considerations range from spatial requirements to the choice between professional installation and a do-it-yourself approach:

- Space Requirements: Before installation, assess the space where the generator will be placed. It should be easily accessible for maintenance, well-ventilated to prevent overheating, and sufficiently protected from environmental factors. According to industry guidelines, there should be enough clearance around the generator to comply with fire safety regulations and to facilitate easy inspection and repair.

- Environmental Factors: The installation site must also consider environmental impacts such as noise and emissions. For businesses in urban areas or close to residential zones, selecting a generator with noise reduction technology and lower emissions is crucial. Cummins generators are equipped with advanced exhaust systems and sound attenuation features to address these concerns.

- Professional Installation vs. DIY: While some businesses might consider installing a generator on their own to cut costs, professional installation is highly recommended for several reasons:

- Safety: Incorrect installation can lead to safety hazards, including fire, electrical failures, or exhaust fume accumulation.

- Compliance: Professional installers are familiar with local codes and regulations, ensuring that your installation adheres to all legal requirements.

- Efficiency: Properly installed generators operate more efficiently, which can extend the lifespan of the unit and reduce operational costs.

- Recommendations for Cummins Generators: For the installation of Cummins commercial generators, it is advisable to use certified Cummins technicians. These professionals have specific training on Cummins models, ensuring that every component is optimally configured for best performance. “Using certified technicians for installation not only ensures that your warranty remains valid but also maximizes the generator’s efficiency and longevity,” explains a Cummins installation expert.

In summary, considering these factors during the installation process can greatly influence the operational success and reliability of your Cummins generator. As we move to the next section, we will discuss the ongoing maintenance needs of these generators to ensure they continue to serve your business effectively and efficiently.

Maintenance and Service

Regular maintenance is pivotal for the longevity and efficiency of your Cummins commercial generator. A well-maintained generator not only performs reliably but also minimizes the risk of unexpected failures that could disrupt business operations. Here are essential aspects to consider for maintaining your Cummins generator:

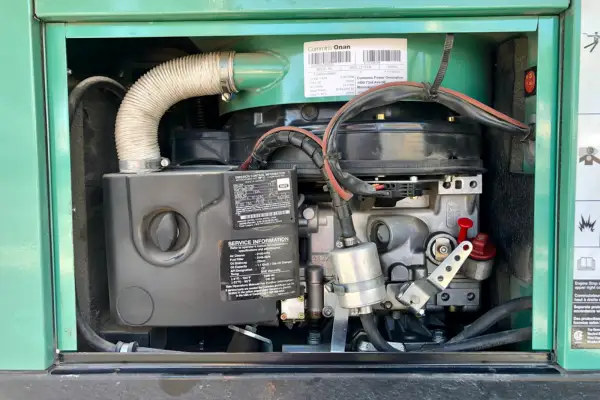

- Routine Maintenance Schedule: Cummins recommends specific maintenance schedules that are tailored to the model and usage patterns of your generator. This typically includes checks and replacements of oil, air, and fuel filters, as well as system diagnostics to ensure all components are functioning correctly. Adhering to these schedules is crucial, as noted by Cummins service technicians, who emphasize that “Regular maintenance is the key to extending the life of your generator and ensuring it operates efficiently when you need it most.”

- Monitoring System Health: Modern Cummins generators are equipped with sophisticated monitoring systems that provide real-time diagnostics and alert operators to potential issues before they lead to failures. These systems track everything from engine performance to fuel consumption and emission levels, allowing for proactive maintenance and adjustments.

- Choosing Service Providers: While some routine checks can be performed in-house, it’s important to have a professional technician service the generator for more complex maintenance tasks. Shandong Huali Electromechanical Co., Ltd service providers ensures that your generator is handled by experts trained specifically in Cummins technology. These professionals can also update you on the latest upgrades or recalls that may affect your model.

- Training for In-House Teams: For businesses that prefer to conduct some maintenance internally, Cummins offers training programs that equip your facility management team with the basic skills needed to care for your generator. These training sessions cover routine maintenance procedures, troubleshooting tips, and safety practices to ensure your staff can handle minor maintenance tasks effectively.

- Record Keeping: Maintain a detailed log of all maintenance activities, including dates, services performed, parts replaced, and any anomalies observed during routine checks. This record is invaluable for troubleshooting future issues and can be essential for warranty support if needed.

By investing in regular maintenance, you ensure that your Cummins commercial generator remains a reliable asset for your enterprise, reducing the likelihood of costly downtime and repairs. In the next section, we’ll explore the financial aspects of owning a Cummins generator, including cost analysis and budget planning, to help you manage the total cost of ownership effectively.

Cost Analysis and Budget Planning

Investing in a Cummins commercial generator is not only about the purchase price but also about understanding the total cost of ownership, which includes maintenance, fuel, and potential downtime costs. Here’s how you can plan your budget effectively:

- Initial Costs vs. Long-Term Investment: The upfront cost of a Cummins generator includes the purchase price and installation. These generators, while potentially higher in initial cost compared to some competitors, are renowned for their durability and lower lifetime costs. “Investing in quality equipment like Cummins generators reduces long-term expenses due to fewer breakdowns and lower maintenance costs,” explains a financial analyst specializing in industrial equipment.

- Operational Costs: These include fuel consumption, regular maintenance, and repair costs. Cummins generators are designed for fuel efficiency, but operational costs can vary based on the model and usage. For example, diesel generators may have higher fuel costs but lower maintenance needs compared to gas models. Calculating these costs will give you a clearer picture of what to expect in terms of ongoing expenses.

- Resale Value: Cummins generators are known for holding their value over time. If maintained properly, these generators can be resold at a competitive price, reducing the overall cost of ownership. This aspect is crucial for businesses that may need to upgrade or change power solutions as they grow.

- Financing Options: Cummins and various distributors offer financing options that can alleviate the burden of a large upfront investment. Exploring these options can provide flexibility in budgeting and help align the purchase with business cash flows.

- Budget for Contingencies: Always set aside a portion of your budget for unexpected repairs or urgent maintenance. This contingency fund helps ensure that sudden expenses do not disrupt your business operations or financial stability.

- Cost-Benefit Analysis: Conduct a thorough cost-benefit analysis that considers not only the financial outlay but also the potential cost savings from reduced downtime and increased efficiency. A Cummins product specialist might suggest, “Assessing the efficiency gains from a reliable power source like a Cummins generator can offset initial expenses through enhanced productivity and operational continuity.”

By carefully planning your budget and considering all these factors, you can ensure that your investment in a Cummins commercial generator is sound and sustainable, supporting your business’s needs effectively over the long term. In the final sections, we will look at real-world applications and case studies that highlight the benefits of Cummins generators in various industries.

FAQs: Common Questions About Cummins Commercial Generators

Navigating the world of Cummins commercial generators can lead to a variety of questions from potential buyers and users. Here are some of the most commonly asked questions, providing concise and informative answers:

- What types of fuel can Cummins commercial generators use? Cummins generators are versatile and can operate on different types of fuel including diesel, natural gas, and some hybrid models that combine fuels for efficiency and environmental benefits. This flexibility allows users to choose the best option based on availability, cost, and environmental regulations.

- How often should a Cummins generator be serviced? The servicing frequency for Cummins generators depends on the model and usage but generally, routine maintenance is recommended every 6 months or after 500 hours of operation. Regular maintenance is crucial to ensure operational efficiency and longevity of the generator.

- Can Cummins generators handle continuous operation? Yes, Designs many of its commercial generators for continuous operation. They are built to handle the demands of extended use, making them ideal for applications like hospitals, data centers, and manufacturing facilities where power needs are critical.

- What warranty options are available with Cummins generators? Offers various warranty options depending on the generator model and application. These can range from basic limited warranties to extended warranties covering additional parts and labor. Potential buyers should consult with a Cummins dealer to understand the specific warranty conditions applicable to their chosen model.

- How does Cummins ensure its generators are environmentally friendly? Is committed to environmental sustainability and designs its generators with eco-friendly technologies. Many models meet stringent emissions standards, use fuel-efficient engines, and some are capable of running on renewable fuels like biodiesel, demonstrating Cummins’ dedication to reducing the environmental impact.

- Can I customize a Cummins generator to fit specific needs? Yes, Cummins offers customization options for most of its commercial generators. Buyers can choose from various configurations, add-on features, and technology upgrades to meet specific requirements. Customization can include adjustments to power output, control systems, and even exterior housing to fit specific operational environments.

References

Cummins Inc. Official Website: Offers an extensive overview of Cummins commercial generators, highlighting their versatility in fuel usage, including diesel and natural gas options, and their applicability in various settings such as data centers and healthcare facilities.

Global Power Supply: Discusses the practical use and advantages of Cummins diesel generators in commercial and industrial facilities. It also touches on the operational characteristics like quick start-up times and load assumption, which are crucial for settings that require reliable backup power solutions

Northern Tool + Equipment: Provides specific product details on smaller scale Cummins generators, ideal for quieter operations with efficient power output, suitable for commercial use where noise levels are a concern