Cummins Inc. stands as a titan in the power generation industry, known globally for its robust and reliable Cummins gas generator systems. Established over a century ago, Cummins has cultivated a reputation for engineering excellence and innovative solutions across various sectors, including residential, commercial, and industrial applications.

The significance of gas generators in today’s energy landscape cannot be overstated. Amidst growing environmental concerns and escalating fuel prices, gas generators offer a cleaner, more sustainable alternative to diesel-powered units. They are pivotal in areas prone to power outages, providing emergency backup and ensuring uninterrupted power supply. Additionally, the flexibility of natural gas availability and the efficiency of gas-powered engines make Cummins gas generators an attractive option for continuous power generation.

Industry expert Dr. John Peterson, a professor of Electrical Engineering at Purdue University, emphasizes the importance of choosing the right generator: “In today’s fluctuating energy market, selecting a generator isn’t just about power—it’s about sustainability, efficiency, and reliability. Cummins gas generators meet these needs by providing adaptable solutions that integrate seamlessly into existing power frameworks.”

As we delve deeper into the capabilities and benefits of these generators, it becomes clear why they are increasingly becoming the backbone of modern energy solutions.

Types of Cummins Gas Generators Available

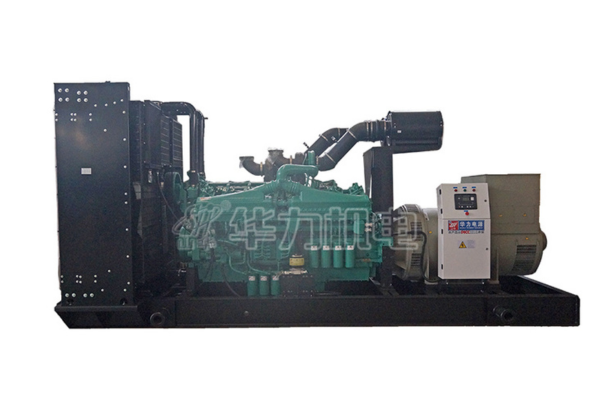

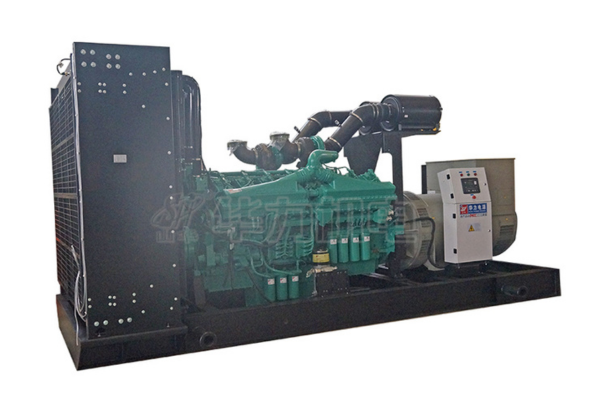

Cummins gas generators are designed to meet a wide range of power requirements and applications, making them ideal for diverse settings from residential homes to large-scale industrial complexes. Each model is tailored to specific needs, ensuring that every customer finds a perfect match for their power generation demands.

Residential Models

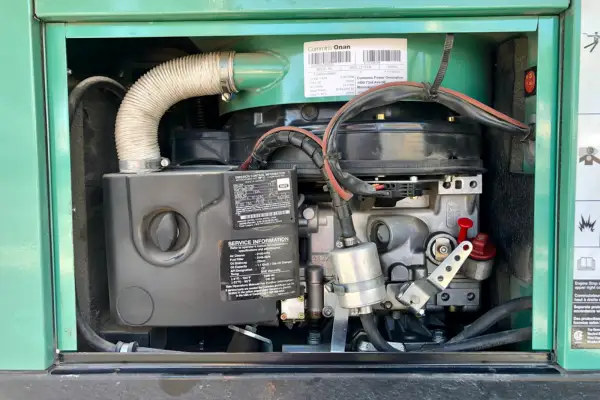

For residential use, Cummins offers compact and efficient generators capable of running on natural gas. These units are designed for minimal noise and space intrusion, ensuring that they can be easily integrated into suburban environments without disrupting daily life. They provide a reliable power backup during outages, ensuring that homes remain lit and appliances keep running smoothly.

Commercial Models

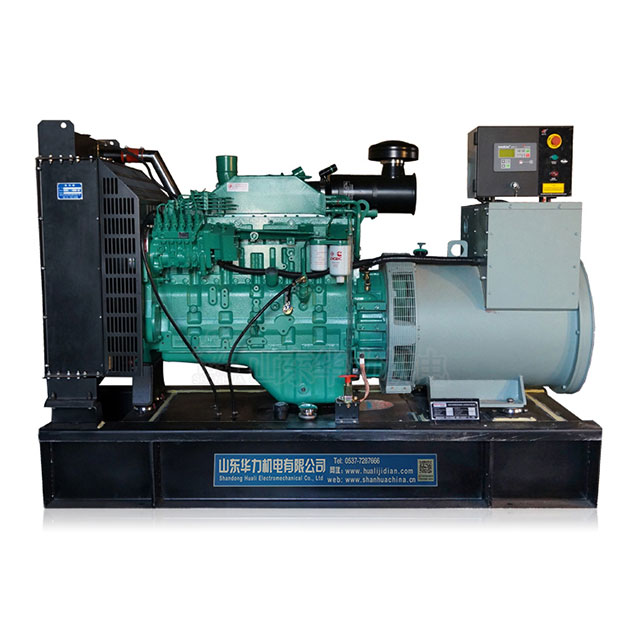

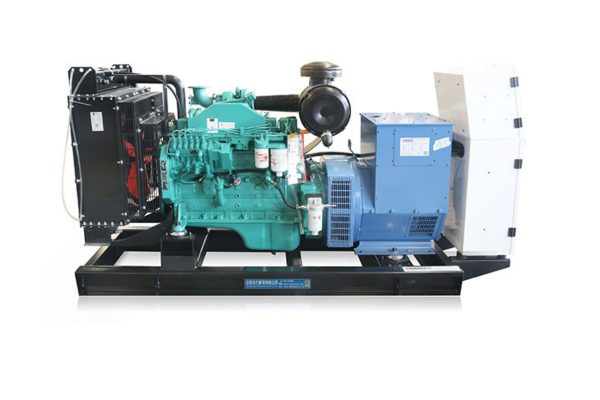

In the commercial sector, Cummins gas generators are known for their robustness and adaptability. These models vary in size and output capabilities, catering to businesses like hospitals, schools, and shopping centers, where power reliability is critical. The commercial generators often feature advanced control systems for easy monitoring and integration with existing electrical systems.

Industrial Models

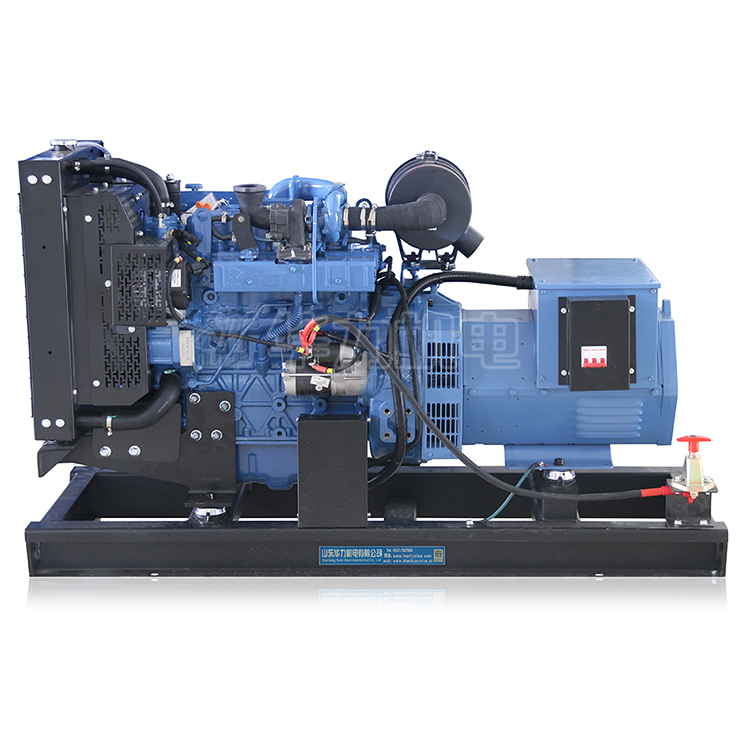

For industrial applications, Cummins manufactures high-capacity generators capable of handling large loads over extended periods. These are essential in factories, data centers, and processing plants, where even a short period of downtime can lead to significant financial losses. Industrial models are engineered for durability and can withstand harsh environments and continuous use.

Dr. Emily Zhang, a leading energy consultant, notes the importance of application-specific generator selection: “Choosing the right Cummins gas generator involves understanding the specific demands of your environment. Industrial models, for example, are not just larger; they are also built to endure the rigors of industrial settings, ensuring reliability and efficiency under any condition.”

Cummins’ range of gas generators demonstrates their commitment to providing tailored solutions that align with the specific needs of their customers, highlighting their role as a versatile and dependable provider in the power generation market.

Key Features of Cummins Gas Generators

Cummins has long been recognized for integrating innovative technologies into their Cummins gas generator models. These key features not only enhance the performance and reliability of their systems but also contribute significantly to environmental sustainability and operational efficiency.

Innovative Technologies

Cummins continually invests in research and development to keep their gas generators at the forefront of technology. Notable advancements include sophisticated control systems that allow for remote monitoring and diagnostics, ensuring optimal performance and easier maintenance. Additionally, many models are equipped with advanced exhaust aftertreatment systems, which help reduce emissions to meet stringent environmental standards.

Reliability and Durability

The reliability of a Cummins gas generator is a testament to the company’s engineering expertise. These generators are designed to provide consistent power under various operational conditions. Their durability is enhanced by using high-quality materials and components that withstand the demands of both frequent use and harsh environmental conditions.

Energy Efficiency and Environmental Benefits

Efficiency is a hallmark of Cummins’ designs. Their gas generators are known for their ability to convert a high percentage of fuel into usable electricity, reducing waste and operating costs. Moreover, natural gas as a fuel source has a lower carbon footprint compared to diesel, making Cummins gas generators a more environmentally friendly choice for power generation.

Industry expert Mark Sullivan, an energy systems analyst, highlights these features: “The innovation in Cummins gas generators isn’t just about energy output. It’s about integrating systems that enhance longevity and reduce ecological impact. Their efficiency and lower emissions reflect Cummins’ commitment to environmental stewardship while providing reliable energy solutions.”

Cummins’ commitment to innovation, reliability, and efficiency ensures that their gas generators are a premier choice for customers looking for dependable, long-term energy solutions that also consider environmental impact.

How to Choose the Right Cummins Gas Generator

Selecting the appropriate Cummins gas generator involves a detailed evaluation of your specific power needs and understanding the characteristics of different models to find the best fit. Here are some key factors to consider when choosing the right generator for your requirements.

Assessing Power Needs

Firstly, calculate the total power requirement of your facility or home by adding up the wattage of all appliances and systems that need to be powered in the event of an outage. It is essential to consider not just the running wattage, but also the starting wattage of equipment, which can be significantly higher due to initial power surges.

Generator Size and Output Capacity

Once you have an understanding of your total power needs, you can match this with the output capacity of available Cummins gas generators. Choosing a generator with a capacity slightly higher than your calculated demand is advisable to ensure it can handle occasional surges without straining the system.

Fuel Consumption and Efficiency

Evaluating the fuel efficiency of a generator is crucial, as this impacts ongoing operational costs and environmental footprint. Cummins designs their generators for optimal fuel efficiency, but selecting a model that balances power output with fuel economy can optimize running costs and decrease emissions.

David Thompson, a renowned power systems engineer, advises, “When selecting a generator, consider the efficiency of the unit. A more efficient generator reduces operational costs over time and lessens environmental impact, making it a prudent long-term investment.”

By thoroughly assessing your power requirements, understanding the specific features of Cummins gas generators, and considering both initial and ongoing costs, you can make an informed decision that ensures reliable and efficient power backup tailored to your needs.

Installation Guidelines for Cummins Gas Generators

Proper installation is crucial for the safe and efficient operation of your Cummins gas generator. Following these guidelines will help ensure that your generator performs optimally while adhering to safety standards and local regulations.

Steps for Safe Installation

- Site Selection: Choose a location that is dry, well-ventilated, and easily accessible for maintenance. It should be away from windows and doors to prevent exhaust gases from entering the building.

- Foundation Preparation: Ensure that the generator sits on a stable, level surface. A concrete pad is typically recommended to reduce vibration and secure the generator firmly.

- Proper Ventilation: Adequate ventilation is critical to prevent overheating and allow for proper exhaust. Make sure the installation site allows for sufficient airflow around the generator.

Compliance with Local Regulations

- Building Codes: Check with your local building authority for any specific codes and standards that apply to generator installation in your area.

- Electrical Codes: Installation must comply with national and local electrical codes to ensure safety. This includes proper wiring and grounding of the unit.

- Noise Regulations: Be aware of any local noise ordinances that may affect the placement and operation of your generator, especially in residential areas.

Robert Lopez, a certified generator installation expert, emphasizes the importance of professional installation: “Installing a Cummins gas generator is not just about following the manual. It requires understanding local codes and ensuring that the setup meets safety and operational standards. Always consider hiring a professional to verify that all aspects of the installation are compliant and safe.”

By following these detailed guidelines and possibly consulting with a professional installer, you can ensure that your Cummins gas generator is set up to provide reliable power while maintaining safety and compliance with all relevant regulations.

Maintenance and Care for Optimal Performance

Regular maintenance is essential for ensuring the longevity and reliability of your Cummins gas generator. Adhering to a comprehensive maintenance schedule not only prevents unexpected breakdowns but also optimizes performance and efficiency over the lifetime of the generator.

Routine Maintenance Tasks and Schedules

- Visual Inspections: Regularly inspect your generator for any signs of wear, leaks, or damage. Check all connections and mounted components to ensure they are secure.

- Oil and Filter Changes: Like any engine, your generator requires regular oil changes. Follow the manufacturer’s guidelines for oil type and change intervals. Similarly, replace air and fuel filters as recommended to ensure efficient operation.

- Battery Maintenance: Check the battery condition and charge level, especially before the storm season, to ensure reliable starting when needed.

Troubleshooting Common Issues

- Failure to Start: This is often due to battery issues or fuel supply problems. Ensure the battery is charged and that there is an adequate fuel supply.

- Irregular Running: If the generator runs erratically, it may be due to dirty filters or injectors. Regular cleaning or replacement can resolve this issue.

- Overheating: Make sure the generator has adequate ventilation. Overheating can occur if the unit is placed too close to walls or other equipment, restricting airflow.

Tips for Longevity

- Regular Testing: Run the generator periodically to ensure it operates smoothly and is ready for emergency use. This also helps to lubricate the engine and prevent the accumulation of sediments in the fuel system.

- Professional Servicing: Schedule annual inspections and servicing by certified professionals. They can perform more complex checks and repairs that go beyond routine maintenance.

Energy consultant Dr. Helen Richards advises, “Maintaining a Cummins gas generator isn’t just about following a checklist; it’s about understanding the operational demands and environmental conditions your generator faces. Tailor your maintenance schedule to fit these variables for optimal performance.”

By investing time and resources into regular maintenance and care, you can significantly extend the life of your Cummins gas generator, ensuring it provides reliable power when you most need it.

Cost Considerations and Return on Investment

Investing in a Cummins gas generator involves evaluating not only the initial purchase price but also long-term operational costs and potential savings. Understanding these financial aspects can help you make an informed decision that maximizes your return on investment.

Understanding Pricing Models

Cummins gas generators come in various models, each priced according to its power output capacity, technological features, and intended use. The initial cost can vary significantly based on these factors, but it’s important to consider the quality and reliability that come with Cummins products when evaluating the price.

Calculating Potential Savings and Benefits

- Reduced Downtime: For businesses, the cost of power outages can be substantial. A reliable generator ensures that operations continue smoothly, saving potentially thousands in lost revenue and productivity.

- Energy Efficiency: Cummins generators are designed for high fuel efficiency, which translates to lower operating costs over the generator’s lifespan. Additionally, using gas as a fuel source typically costs less than diesel, providing further savings.

- Maintenance Costs: Regular maintenance is a factor in the total cost of ownership, but the robust design of Cummins generators often means less frequent repairs and lower maintenance costs compared to less reliable brands.

Paul Green, a financial analyst specializing in energy investments, notes, “The upfront cost of a Cummins gas generator might be higher than some competitors, but when you factor in the efficiency, reliability, and lower maintenance costs, the total cost of ownership is often much lower.”

By carefully considering both the immediate and long-term financial implications of purchasing a Cummins gas generator, you can ensure that your investment not only meets your current power needs but also contributes to financial efficiencies and operational stability in the future.

FAQs: Common Questions About Cummins Gas Generators

When considering the purchase of a Cummins gas generator, potential buyers often have a range of questions regarding the capabilities and requirements of these units. Here are answers to some of the most frequently asked questions:

What is the expected lifespan of a Cummins gas generator?

Cummins gas generators are designed for longevity, typically lasting between 10,000 to 30,000 hours of operation, depending on the model and how well they are maintained. Regular maintenance and proper installation can significantly extend the lifespan.

How often should I perform maintenance on my generator?

Routine maintenance schedules vary based on the model and usage but generally include regular checks every few months and more comprehensive annual services. Always refer to the user manual specific to your model for detailed maintenance guidelines.

Can Cummins gas generators run continuously?

Yes, many Cummins gas generators are built to run continuously, especially those designed for industrial applications. They are an ideal choice for locations that require constant power, such as hospitals or manufacturing plants.

Are there any specific safety concerns to consider?

Safety is paramount when operating any generator. Ensure that your Cummins gas generator is installed in a well-ventilated area to avoid carbon monoxide buildup. It should also be placed away from flammable materials and operated according to the manufacturer’s guidelines.

How does the cost of running a gas generator compare to other types?

Running a gas generator generally costs less than operating a diesel generator due to the lower price of natural gas compared to diesel fuel. Additionally, gas generators are often more fuel-efficient and have lower emissions, which can translate to cost savings in terms of environmental compliance and fuel consumption.

What support does Cummins offer for their gas generators?

Cummins provides comprehensive support, including customer service, technical support, and parts availability through its global network. They also offer warranty options that cover various components and labor, ensuring that your investment is protected.

By addressing these common queries, prospective buyers can better understand the value and operation of Cummins gas generators, ensuring they make an informed decision suited to their specific power needs.

References

QSK60G Gas Generator Series: This series is known for its energy efficiency and versatility in applications such as prime and peaking power. It features advanced lean burn technology, which ensures low emissions and high efficiency, with features designed for easy integration and reliable performance in diverse conditions

HSK78G Gas Generator Series: Recognized for its high electrical efficiency and fuel flexibility, the HSK78G series can operate on a wide range of gas qualities without performance degradation. This series is particularly noted for its ability to handle aggressive fuels and conditions while maintaining low operational costs and high uptime

General Product Range: Cummins offers a broad range of natural gas generators ranging from 55 kW to 2000 kW. These generators are designed for different market needs, including standby and prime power applications. They are equipped with NOx sensors to meet strict emission standards, ensuring efficient and compliant operations across various applications