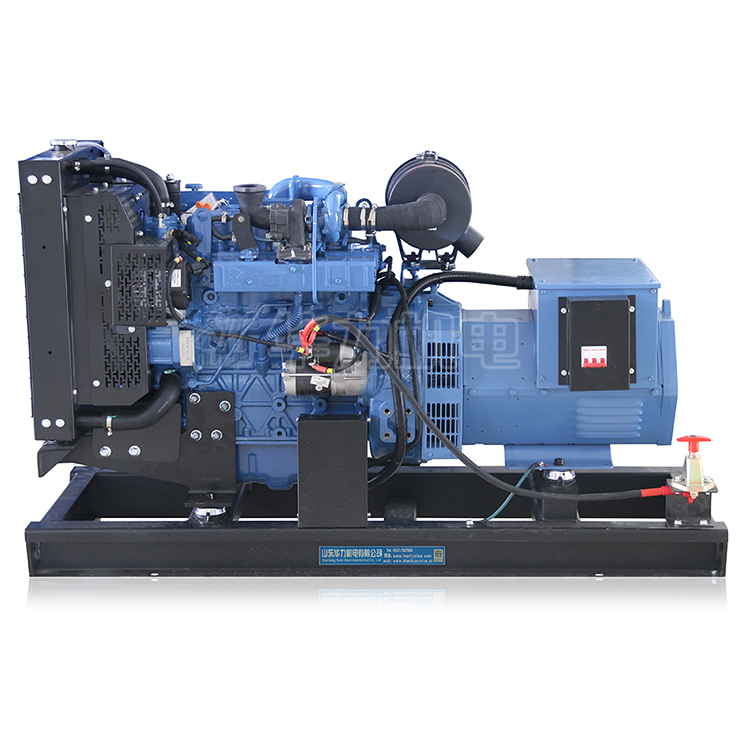

Maintaining a Cummins generator is crucial for ensuring reliability, efficiency, and a long operational life. Regular Cummins generator maintenance is not just about fixing problems as they arise but about preventing them in the first place, thereby reducing downtime and saving on costly repairs.

Why Maintenance is Critical: Cummins generators are integral to operations in industries where power supply consistency is critical, such as hospitals, data centers, and manufacturing plants. Ensuring these generators operate efficiently is paramount. According to James O’Brien, a senior engineer with over 20 years in power generation, “Regular maintenance of your Cummins generator can enhance performance by up to 20% and extend its lifespan significantly.”

Key Benefits of Regular Maintenance:

- Improved Efficiency: Regular servicing ensures that every component operates at peak efficiency, which can significantly reduce fuel consumption and operating costs.

- Extended Lifespan: Routine maintenance prevents the excessive wear and tear that can shorten a generator’s lifespan.

- Reliability and Safety: Systematic checks and balances reduce the risk of sudden failures that could lead to safety hazards or operational disruptions.

- Compliance and Warranty: Keeping up with scheduled maintenance ensures compliance with warranty requirements and industry regulations.

This introduction sets the stage for a deep dive into the components of a Cummins generator and how each contributes to the overall functionality and maintenance needs of the system. Understanding these elements will enable operators to implement a maintenance schedule that ensures optimal performance and longevity.

Understanding Your Cummins Generator

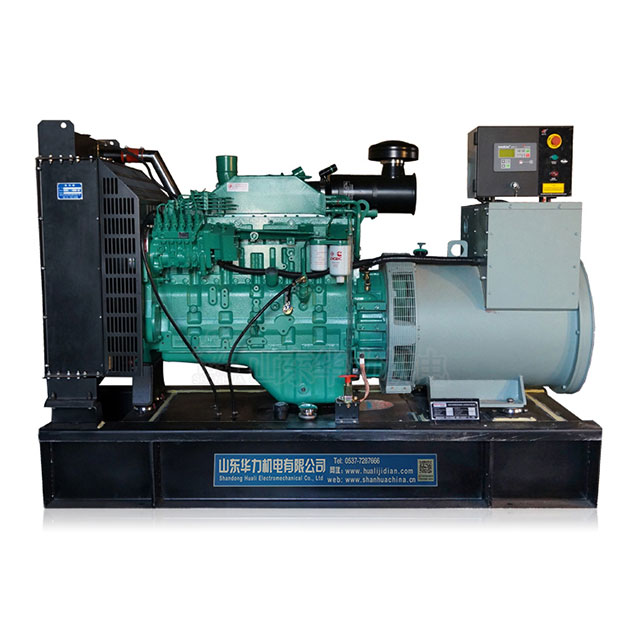

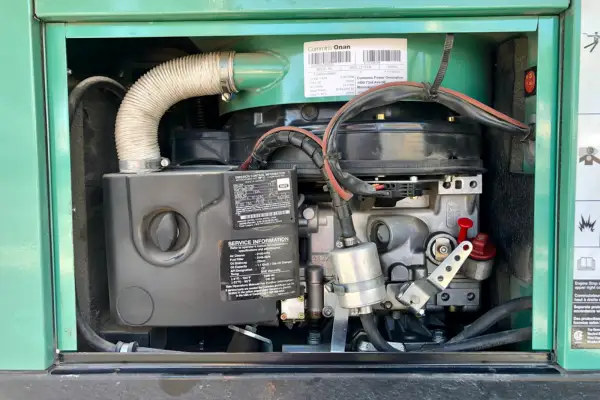

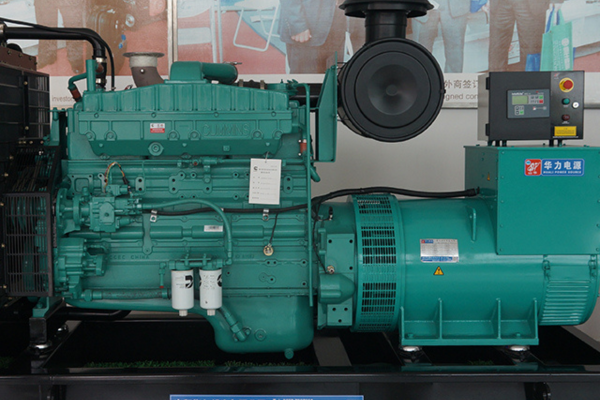

To effectively maintain a Cummins generator, it’s essential to have a thorough understanding of its major components and how they contribute to its operation. Cummins generators are complex systems composed of several critical parts, each playing a distinct role in the functionality of the generator.

Breakdown of Major Components:

- Engine: The heart of the generator, where fuel is converted into mechanical energy. This component is crucial for the power generation process and requires regular checks like oil changes, filter replacements, and cooling system maintenance.

- Alternator: Converts mechanical energy from the engine into electrical energy. Key maintenance tasks include checking the bearings, cleaning the slip rings, and ensuring electrical connections are tight and free from corrosion.

- Control System: The brain of the generator, which monitors and controls the generator’s operations. Maintenance involves ensuring that all electronic components are functioning correctly, firmware is up to date, and settings are properly calibrated according to the operational requirements.

- Fuel System: Includes the fuel tank, pumps, filters, and injectors. It is vital to maintain clean and uncontaminated fuel to avoid issues like clogging and premature wear of the engine components.

- Cooling and Exhaust Systems: Keep the generator from overheating and ensure that emissions are safely expelled. Regular checks should include inspecting coolant levels, hoses, and the radiator, as well as ensuring the exhaust system is unobstructed.

- Lubrication System: Minimizes wear and tear on moving parts within the engine. It’s essential to use the correct type of oil and regularly check and replace the oil and oil filters.

- Battery System: Powers the generator’s control system and helps start the engine. Battery maintenance includes ensuring it is fully charged, terminals are clean, and the battery is tested regularly for optimal performance.

Understanding the Contribution of Each Part:

Each component of your Cummins generator works together to ensure smooth and efficient operation. The engine provides the necessary power, the alternator turns that power into usable electricity, and the control system ensures everything is running as it should. Disruptions in any part can lead to operational inefficiencies or generator failure.

Expert insights from professionals like Dr. Karen Maxwell, a mechanical engineer specializing in power systems, highlight the importance of component education. She notes, “Understanding each component’s role not only aids in targeted maintenance but also enhances the ability to quickly diagnose and fix any issues that may arise.”

Daily and Weekly Maintenance Checks

Regular maintenance checks are pivotal to the continuous operation and longevity of your Cummins generator. By establishing and adhering to daily and weekly maintenance routines, you can catch and rectify small issues before they evolve into major problems.

Daily Maintenance Checks:

- Visual Inspection: Begin each day with a visual check of the generator. Look for any signs of wear, leaks, or damage. Check that all connections are tight and that there is no accumulation of debris around the unit.

- Check Fluid Levels: Essential fluids such as oil, coolant, and fuel should be checked daily. Low levels can indicate leaks or consumption issues that need to be addressed promptly to avoid engine damage.

- Battery Inspection: Ensure that the battery is fully charged and that connections are clean and tight. A failing battery can prevent the generator from starting when needed.

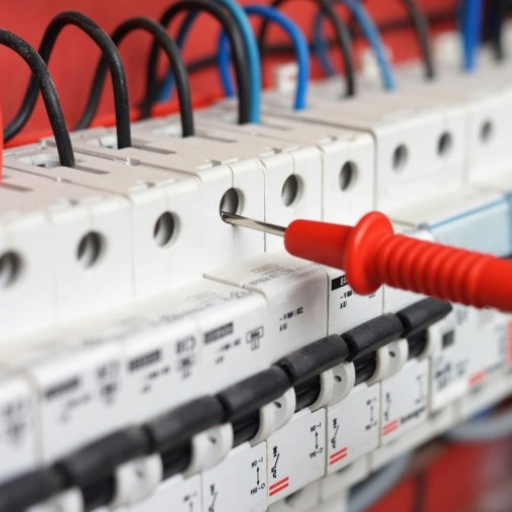

- Control Panel: Review the control panel for any warning lights or error messages. This can indicate issues that may require immediate attention.

Weekly Inspections:

- Test Run: Conduct a weekly test run to ensure the generator operates correctly and to check for any unusual noises or vibrations that could indicate mechanical issues.

- Air Filter Check: Inspect the air filter for dirt and debris, which can impede air flow and reduce engine efficiency. Clean or replace the air filter as needed.

- Fuel System: Inspect the fuel system for leaks and ensure that the fuel filters are clean. Dirty filters can lead to poor engine performance and increased wear.

- Cooling System: Check the cooling system for proper coolant level and signs of leaks. Ensure that the radiator and air intake are clean and unobstructed.

Regularly performing these checks not only ensures that your Cummins generator is always ready to perform but also extends its service life and optimizes its efficiency. Michael Thompson, a certified generator technician, emphasizes the importance of consistency in maintenance: “Routine checks are the first line of defense in preventing generator failures. Regular oversight can significantly reduce emergency repairs and associated costs.”

These preventive measures, when done diligently, provide peace of mind knowing that your Cummins generator will perform reliably in times of need, safeguarding against unexpected downtimes and costly disruptions.

Monthly and Seasonal Maintenance Routines

Cummins generators require not only daily and weekly checks but also comprehensive monthly and seasonal maintenance routines. These are designed to ensure optimal performance throughout the year, adapting to varying operational demands and environmental conditions.

Monthly Maintenance Tasks:

- Oil and Filter Change: Depending on usage, change the oil and oil filters monthly to ensure engine cleanliness and efficiency. Used oil can accumulate contaminants that damage the engine.

- Fuel System Inspection: Inspect and clean the fuel lines and replace the fuel filters. This prevents blockages and ensures that the engine receives clean fuel, crucial for maintaining performance and preventing wear.

- Cooling System Service: Flush the cooling system and replace the coolant as recommended by the manufacturer. Check all hoses, clamps, and the radiator cap for wear and replace as necessary to prevent leaks and overheating.

- Exhaust System Check: Inspect the exhaust system for corrosion, damage, or blockages. Ensuring the exhaust flows freely is essential to maintain proper engine function and safety.

Seasonal Maintenance Checks:

- Prepare for Cold Weather: In colder months, check the antifreeze levels and heater operation to ensure the generator will start in low temperatures. Battery performance should also be monitored closely, as cold weather can reduce battery efficiency.

- Summer Readiness: Before hot weather sets in, clean any debris from the air intakes and cooling fins to prevent overheating. Verify that all fans and thermostats are working correctly.

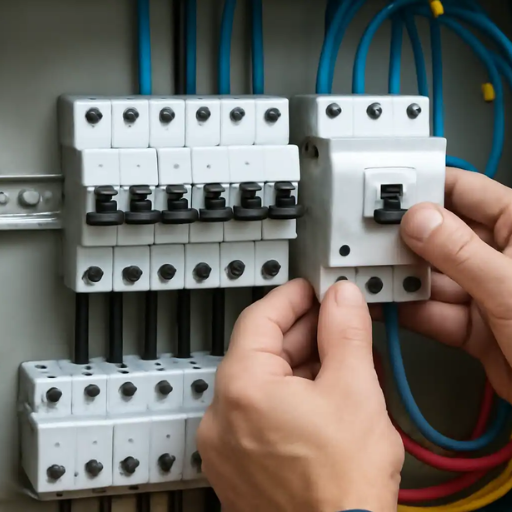

- Electrical System Verification: Inspect and test all electrical connections and components, including the alternator and starter motor, for signs of wear or corrosion. Tighten connections as needed to ensure reliable startup and operation.

- Vibration Analysis: Conduct vibration tests to identify any misalignment or imbalance that could cause operational issues. This is particularly important for generators that operate continuously or under high loads.

Implementing these comprehensive maintenance tasks can significantly enhance the generator’s reliability and efficiency. Expert in power systems, Dr. Lisa Reynolds, advises, “Seasonal adjustments are critical for the longevity of power equipment. They adapt the machine to operate efficiently under different environmental stresses, thus preventing premature failures.”

By diligently following these monthly and seasonal maintenance guidelines, you ensure that your Cummins generator remains in peak condition, ready to handle any power requirements with reduced risk of unexpected failures. This proactive approach not only saves money on repairs but also ensures continuous, reliable service from your generator.

Common Issues and Troubleshooting

Cummins generators, like any mechanical systems, can face a range of common issues that can impede their functionality. Recognizing these problems early and knowing how to troubleshoot them effectively is crucial to maintaining uninterrupted service.

Identifying Frequent Problems:

- Starting Failures: Often caused by battery issues, fuel supply problems, or faulty electrical connections. Ensure that the battery is fully charged and that connections are clean and secure. Also, check for any fuel line blockages or dirty fuel filters.

- Overheating: This can occur due to a malfunctioning cooling system or blocked air passages. Regularly check the coolant levels, clean the radiator and air passages, and ensure the fan is functioning properly.

- Uneven Running or Misfiring: These issues may be due to problems in the fuel injection system or air intake issues. Inspect and clean air filters and check the injectors for blockages or wear.

- Low Power Output: This could be a sign of restricted fuel delivery, air intake issues, or exhaust blockages. Ensure that fuel and air filters are clean and that the exhaust system is clear.

Step-by-Step Troubleshooting Guide:

- Diagnose the Problem: Begin by checking the most common sources of trouble mentioned above. Use diagnostic tools such as a multimeter to check electrical components and pressure gauges for fuel and oil pressures.

- Consult the Control Panel: Modern Cummins generators have sophisticated control panels that provide error codes and system information that can help pinpoint problems.

- Check the Manual: Always refer to the Cummins generator’s manual for specific troubleshooting tips and error code explanations relevant to your model.

- Resolve the Issue: Once identified, resolve the issue based on the manufacturer’s recommendations. This may involve replacing worn-out parts, cleaning components, or adjusting system settings.

- Test the Generator: After making repairs, run the generator to ensure it is operating correctly and monitor it for any signs of further issues.

Expert Advice:

Tom Sanders, a veteran generator mechanic, emphasizes the importance of a methodical approach: “Always start with the simplest solutions when troubleshooting. Many times, the issues are basic and can be solved with minimal technical skills. However, if the problem persists, don’t hesitate to call in a professional.”

This systematic approach to troubleshooting can help minimize downtime and extend the life of your Cummins generator. By staying vigilant and responsive to signs of trouble, you can ensure your generator remains reliable, regardless of the conditions.

Professional Maintenance and Support

While routine maintenance can be handled in-house, there are situations when it’s crucial to seek professional maintenance and support for your Cummins generator. This ensures that complex issues are addressed properly and can significantly extend the operational lifespan of the generator.

When to Seek Professional Help:

- Complex Electrical Issues: If you encounter persistent electrical faults or the generator’s control system indicates problems that are not resolved with basic troubleshooting, it’s time to call in the experts.

- Major Component Failure: Issues like a failed alternator, engine overhaul, or significant repairs that go beyond routine maintenance require professional skills and tools.

- Regular Scheduled Service: Cummins recommends certain services be performed by certified professionals to maintain warranty conditions and ensure high-quality work that doesn’t compromise the generator’s performance.

Choosing the Right Service Provider:

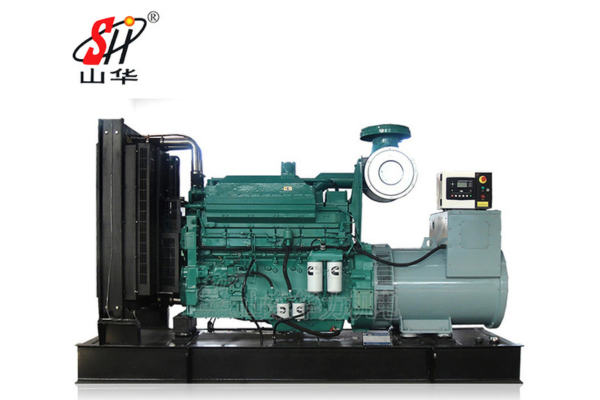

- Certification and Experience: Look for service providers that are certified by Cummins. This ensures they have the training and expertise necessary to handle Cummins generators specifically.

- Reputation and Reviews: Check the provider’s reputation through reviews and testimonials. A reliable service provider should have a track record of quality service and customer satisfaction.

- Availability of Genuine Parts: Ensure the service provider uses genuine Cummins parts. This is crucial for maintaining the integrity and performance of your generator.

- Support Agreements: Consider service providers that offer comprehensive maintenance agreements. These agreements can cover everything from routine maintenance to emergency services, ensuring your generator is always in top condition.

Expert Insight:

According to John Grant, a senior service engineer at Shandong Huali Electromechanical Co., Ltd., “Professional maintenance is not just about fixing problems. It’s about leveraging expert knowledge to optimize the generator’s performance and reliability over its lifecycle.” He emphasizes the importance of using authorized service centers that provide detailed service reports and follow Cummins’s guidelines closely.

Engaging professional maintenance services ensures your Cummins generator is serviced correctly with the latest diagnostic tools and technologies. This not only helps in effectively managing complex issues but also aligns with Cummins’s guidelines to ensure maximum efficiency and reliability of your power solutions.

Advanced Maintenance Techniques

For Cummins generator owners and technicians aiming to elevate their maintenance practices, understanding and implementing advanced maintenance techniques can provide significant benefits. These techniques not only enhance the operational efficiency of the generators but also preemptively address potential issues before they escalate into costly repairs.

Advanced Tools and Techniques:

- Vibration Analysis: This technique involves measuring the vibrations of the generator to identify imbalances, misalignment, or bearing failures. Regular vibration analysis can help predict and prevent mechanical failures.

- Thermal Imaging: Using thermal cameras to inspect the generator can reveal hot spots that indicate electrical faults, insulation failures, or other issues that aren’t visible to the naked eye.

- Oil Analysis: Regular analysis of engine oil can provide insights into the condition of an engine. It detects contaminants like metal particles, fuel, or coolant, which can indicate early signs of wear or failure.

- Remote Monitoring Systems: Installing remote monitoring can help track the performance and health of the generator in real-time. This technology alerts you to any irregularities immediately, allowing for prompt action.

Maintaining Newer Cummins Generator Models:

Newer models of Cummins generators often come equipped with advanced features and electronics that require specific maintenance strategies:

- Software Updates: Keeping the generator’s software updated is crucial for maintaining its functionality and efficiency. Regular updates can fix bugs, improve performance, and add new features.

- Calibration of Control Panels: Regular calibration ensures that the control systems are accurate and responsive. This is particularly important for generators used in critical applications where precise power output is necessary.

- Specialized Component Checks: Newer models may include components not found in older models, such as advanced emissions control systems, which require specific expertise and handling.

Expert Recommendation:

Dr. Helen Zhou, a specialist in power generation technology, suggests, “Advanced maintenance techniques like predictive maintenance not only extend the lifespan of the generator but also optimize its performance. Techniques like vibration analysis and thermal imaging should be part of your regular maintenance schedule.”

By incorporating these advanced techniques into your maintenance routine, you can ensure that your Cummins generator operates at peak efficiency and reliability. This proactive approach to maintenance not only saves money in the long run but also ensures that your generator is always ready to perform when needed, thus providing peace of mind and operational continuity.

Conclusion

In this comprehensive guide, we have explored key strategies and techniques for maintaining Cummins generators, emphasizing the importance of regular and advanced maintenance to ensure their reliability and longevity. By following the outlined daily, weekly, monthly, and seasonal maintenance schedules, generator owners can prevent common issues and ensure their systems operate at peak efficiency.

Summarizing Key Maintenance Strategies:

- Regular Checks: Daily visual inspections and fluid level checks are crucial. Weekly, monthly, and seasonal routines help address and prevent operational issues before they become critical, preserving the generator’s integrity and functionality.

- Advanced Techniques: Employing advanced maintenance techniques such as vibration analysis, thermal imaging, and oil analysis can dramatically enhance the ability to predict and prevent failures. These methods allow for a deeper understanding of the generator’s condition and can forecast potential issues before they manifest.

- Professional Support: For complex issues beyond the scope of routine maintenance, seeking professional help from certified technicians ensures that the generator is serviced correctly. Using authorized service centers guarantees that maintenance is performed to the highest standards, using genuine parts and advanced diagnostic tools.

Final Thoughts:

Maintaining your Cummins generator is not merely about fulfilling warranty requirements or avoiding breakdowns; it’s about ensuring operational excellence and reliability in power generation. Implementing a consistent maintenance schedule, utilizing both traditional and advanced techniques, and relying on professional expertise when necessary will extend the life of your generator and ensure it provides reliable service when you need it most.

By embracing these maintenance practices, Cummins generator owners can achieve peace of mind and operational efficiency, knowing that their power systems are in optimal condition, ready to handle any demand. This guide not only serves as a resource for effective generator maintenance but also as a tool to enhance the overall performance and reliability of your power solutions.

FAQs: Common Questions About Cummins Generator Maintenance

Q1: How often should I perform maintenance on my Cummins generator?

- A: Maintenance frequency depends on the generator model and the conditions under which it operates. Generally, daily checks, monthly inspections, and annual servicing are recommended. Refer to your specific model’s manual for detailed guidelines.

Q2: What are the most critical maintenance tasks for a Cummins generator?

- A: Key maintenance tasks include checking and changing oil, inspecting and replacing air and fuel filters, testing the battery, and ensuring the cooling system is functioning properly to prevent overheating.

Q3: Can I perform Cummins generator maintenance myself?

- A: Basic maintenance such as visual inspections and simple replacements (like filters and oil) can often be done by the owner. However, more complex tasks, especially those involving the electrical system and engine diagnostics, should ideally be handled by a professional.

Q4: What signs indicate that my Cummins generator needs immediate attention?

- A: Warning signs include difficulty starting, unusual noises, frequent power outages, excessive vibrations, and visible smoke during operation. Any of these symptoms suggest that a thorough inspection and possibly professional maintenance are needed.

Q5: How do I know if my Cummins generator’s battery is still good?

- A: Check the battery’s charge level regularly with a voltmeter. If it consistently shows a low charge or the generator has trouble starting, it might be time to replace the battery.

Q6: What is the importance of using genuine Cummins parts for maintenance?

- A: Using genuine Cummins parts ensures compatibility and reliability. Non-genuine parts may not meet Cummins’ specifications and could lead to performance issues or void warranties.

References

Scheduled Maintenance Procedures: Cummins provides a detailed guide on the necessary checks and maintenance activities. This includes checking the cooling system, air intake system, fuel system, and exhaust system regularly to ensure everything is functioning correctly and efficiently.

Maintenance Frequency and Tips: It is advised to follow the operator’s manual for routine maintenance, which should be performed more frequently under extreme temperature conditions or in dusty environments. Regular starting of the generator and logging the hours run are also recommended to optimize service life and support warranty claims.

Professional and Planned Maintenance: Cummins offers planned maintenance programs through their service network. These programs include regular inspections, load testing, full service, and fluid analysis to prevent unforeseen failures and ensure the generator sets are ready when needed.

Technical Support and Resources: Cummins provides access to engine manuals, safety datasheets, warranty information, and more through their technical support and resources. This is essential for performing accurate maintenance and repairs.