To ensure that your Cummins generator oil type works effectively and lasts longer, it is important to choose the right oil type. This is because the correct oil type can greatly improve your generator’s fuel efficiency, engine protection as well as minimize its maintenance while using a wrong one may result in various problems causing damage to your generator.

Advantages of Using Appropriate Oil Type

- Better Performance: It enhances smooth running of the generator with an even power output at all times. The friction between engine components is reduced by proper lubrication which makes it more efficient.

- Engine Protection: A good quality oil provides a blanket over engine parts, thus reducing wearing away. Also, it is helpful in heat dissipation; hence no overheating and thereby extending the life of the engine.

- Enhanced Fuel Efficiency: The use of recommended oil types increases fuel efficiency in a generator. Proper lubrication eases the workload on an engine thus resulting into lower fuel consumption and operational expenses.

- Less Maintenance: In order for a sludge or deposits buildup not to occur inside an engine, one needs to make sure that he or she has picked up the right oil type. Clean oil means that there are no contaminants within an engine which might destroy their working system after some time.

- Optimum Performance under Different Conditions: The cummins generator oil type are designed for different climatic conditions. Therefore, always ensure you have used this kind of oil whether you are operating yours in very hot or cold temperature conditions.

Consequences of Using Wrong Oil

More Friction And Wear Out: Once inappropriate lubricants are used on these engines they would rather not get smoothened during motion processes leading to them getting eroded faster hence replacing them will require more amounts than expected leading to unnecessary expenses incurred here.

- Performance Deterioration:Inadequate oils can negatively affect how generators work. Inappropriate selection of oils may lead to poor functioning like when there is reduced power output among other factors.

- Engine Overheating: The wrong oil may not remove heat in an appropriate manner leading to overheating of the engine. If it heats up, then there might be a permanent damage on the engine that may at times result in a total breakdown.

- Sludge And Deposits Formation: An incorrect use of oil which does not meet the requirements for a generator can lead to sludge and deposit accumulations. These impurities can block some parts of an engine causing its poor functionality thus necessitating more frequent services.

- Voidance Warranty Periods: Cummins does stipulate their own types of oils which must always be used with these engines to enhance better operations and guarantee on validity of warranties as any other type will simply render all this invalid thereby calling for damages.

To sum up, one should consider finding out the correct oil type for his or her Cummins generator so as to ensure that its performance is maintained and safeguarded from maintenance costs. In this way, your generator will work reliably and efficiently as per the manufacturers’ directions because you also get peace of mind since such scrutiny warrants long term value.

Understanding Cummins Generator Oil Specifications

For Cummins generator, choose the right oil by understanding the oil requirements specific to Cummins. These requirements ensure that your engine performs optimally by using a lubricant that provides adequate protection, lubrication and performance for your generator. Let’s delve into these specifications as well as what should be considered when selecting oil.

An Outline of Oil Requirements for Cummins Generator

Cummins generators are designed to work with oils that meet particular specifications. The generator’s handbook provides these standards which have been presented through extensive testing and engineering considerations. The major reason behind this is to make sure that the given oil is able to;

- Lubricate Engine Components: Provide a defensive barrier reducing friction between moving components.

- Dissipate Heat: Take heat from key areas of the engine so as to avoid overheating.

- Clean Engine Parts: Ensure that contaminants do not enter into the engine are free of deposits or sludge.

- Prevent Corrosion: Protect the parts from corrosion and wear hence ensuring their durability.

Using oils meeting Cummins’ specification helps in maintaining reliability, efficiency, and long life of a generator. It also conforms with warranty conditions and reduces risk to damage an engine.

Key Factors

There are several factors you must consider before settling on any oil for your Cummins generator in order to satisfy its required specifications they include:

Viscosity-This describes how thick an oil is and therefore how it flows at various temperatures; normally indicated by two numbers (e.g., 10W-30). The first number shows how viscous it is when cold (during start up), while the second indicates its viscosity at high temperature (normal operating temperature). In case of cummings generators, use recommended viscosity oils which will help in having better performance under different temperatures.

Additives:Additives are chemicals added into oil with an intention of enhancing its function such as:

- Detergents: They help keep engines clean by preventing deposits or sludge from forming.

- Dispersants: Stop contaminants from sticking on engine surfaces by suspending them in oil.

- Anti-wear Agents: To reduce wear and tear, they form protective films on engines parts.

- Corrosion Inhibitors: These protect engines parts from rusting or corroding.

- Viscosity Modifiers: They improve the viscosity of oil across a broad range of temperature.

API Classification – The American Petroleum Institute (API) rates oils based on performance standards. Cummins specifies oils meeting particular API classifications (such as CJ-4, CK-4) to make sure that they offer enough protection and performance for their machines’ engines. Always refer to the generator’s manual for the recommended API classification.

Operating Conditions– These include factors such as ambient temperature, load, and run time among others. For instance, generators operating in extremely cold climates may need oils with lower viscosity grades so as to have better cold start quality while those located in hot areas may require high temperature grade oils that remain viscous at high temperatures under operating conditions.

Synthetic vs Conventional Oil – Synthetic lubricants are purposely made to deliver more than natural lubricants can offer i.e. superior performance and protection. Commonly these achieve improved viscosity stability, better temperature resistance and enhanced engine protection qualities. Though it could be costly using synthetic oils could be useful when using generators under heavy loads or extreme conditions because of above benefits.

In conclusion, maintaining the performance and lifespan of your generator is critical in understanding Cummins generator oil specifications. The right oil to use on your Cummins generator for a smooth and efficient running can be determined by considering factors such as viscosities, additives, API classifications and operating conditions. Always refer to the generator’s manual for specific oil recommendations and always follow Cummins’ guidelines for best performance.

Recommended Oil Types for Cummins Generators

Selecting the right oil type is crucial for the optimal performance and longevity of Cummins generators. cummins generator has specific recommendations for oil types that are best suited to their generators’ engines, ensuring that they perform at their peak and maintain durability over time. Here, we provide a list of recommended oil types along with detailed specifications for each.

List of Recommended Oil Types by Cummins

cummins generator recommends high-quality diesel engine oils that meet their stringent specifications. Below are some of the commonly recommended oil types suitable for Cummins generators:

- SAE 15W-40: This is one of the most commonly recommended oil types for Cummins generators operating in a wide range of ambient temperatures. It is suitable for most environments and offers excellent protection.

- SAE 10W-30: Recommended for use in colder climates, this oil provides good flow at lower temperatures, ensuring smooth start-ups and effective lubrication during cold weather operations.

- SAE 5W-40 Synthetic: For generators operating in extreme conditions, whether cold or hot, synthetic 5W-40 oil offers superior viscosity control and engine protection compared to conventional oils.

Each of these oil types is designed to meet specific Cummins specifications such as CES 20081 or CES 20078, which are tailored to the needs of modern diesel engines.

Detailed Specifications of Each Recommended Oil

- SAE 15W-40

- Viscosity: Ideal for a wide range of operating temperatures, providing a good balance between high-temperature film strength and low-temperature flowability.

- Additives: Includes detergents, dispersants, oxidation inhibitors, and anti-wear agents to ensure cleanliness and protection of engine components.

- API Classification: Typically meets or exceeds API CK-4/SN standards, ensuring high levels of engine cleanliness and wear protection.

- SAE 10W-30

- Viscosity: Lower viscosity grade allows for better flow at lower temperatures, enhancing cold start performance and reducing wear.

- Additives: Similar to 15W-40, with modifications to suit colder operating environments.

- API Classification: Generally meets API CK-4/SN standards, suitable for newer engine designs requiring lower viscosity oils for better fuel economy.

- SAE 5W-40 Synthetic

- Viscosity: Provides excellent performance across a broad temperature range, with enhanced low-temperature capabilities compared to conventional oils.

- Additives: Enhanced additive package for superior stability under thermal and oxidative stress, ideal for extreme conditions.

- API Classification: Often exceeds API CK-4/SN standards and may include additional specifications such as Cummins CES 20086 for high-performance engines.

When selecting oil for your Cummins generator, it is important to refer to the specific model’s user manual or consult with a Cummins authorized service provider to ensure compatibility with your generator’s engine. The right oil type will not only extend the life of the engine but also optimize its performance and efficiency. Regular maintenance, including timely oil changes with the correct oil type and specifications, is essential for maintaining the operational reliability of your Cummins generator.

Maintenance Tips for Optimal Generator Performance

In order for your Cummins generator to be able to perform efficiently and reliably throughout its entire useful life, it must be properly maintained. Regular maintenance prevents unexpected breakdowns, extends the generator’s lifespan and ensures that it can operate optimally when required. Here is a list of key maintenance tips that will help you keep your generator good as new.

Regular Oil Change Intervals

Changing the oil of your generator at regular intervals is most important for its engine well-being. In this way, contaminants are expelled from the oil and it is ensured that the engine remains suitably lubricated.

- Manufacturer’s Recommendations: Always follow the recommended oil change intervals by Cummins as stated in your generators’ manual. Typically, one should change oil after every 100-200 hours of operation or annually depending on whichever comes first.

- Frequent Use: If you use the generator regularly or put too much load on it then, you should consider changing oils more frequently so that it can work perfectly.

- Seasonal Maintenance: When doing seasonal repairs including but not limited to heavy usage or storage before and after these periods do not forget to change oils.

Monitoring Oil Levels and Quality

Checking of oil levels and quality on a regular basis helps prevent problems with engines and keep generators running smoothly.

- Oil Level Check: Prior to each use, check the level of oil at least once per month. Ensure that the machine is placed on an even ground when measuring for the quantity of oil available. Add oil if required without overfilling.

- Oil Quality: You need to look out for signs such as milky coloration which signifies water contamination or grittiness which indicates dirt in case there could be any in it. Clean non-cloudy oil is important so as to ensure good lubrication.

- Dipstick Inspection: The dipstick will show you if there is enough oil inside your engine as well as whether its condition reflects a healthy motor. After wiping clean the dipstick, fully insert it and then pull out to verify the oil level and its appearance.

Additional Maintenance Practices to Prolong Generator Life

Apart from regular oil changes and monitoring, there are other maintenance practices that can enhance the life span of your Cummins generator.

- Air Filter Replacement: Replace air filters as indicated in the manufacturer’s timetable or more often if you run them in dusty areas. A clean air filter will allow proper airflow into the engine and keep contaminants out.

- Fuel System Maintenance: Check fuel filters periodically in order to ensure delivery of clean fuel into an engine. Also inspect for any leakages or damage on lines that supply fuel and clear of foreign matter the tank after some time.

- Battery Maintenance: Ensure that a battery is charged and maintained properly assuming one’s generator has an electric start. Clean battery terminals regularly and check electrolyte levels as well.

- Cooling System Check: Verify proper functioning of the cooling system through inspection of coolant level, radiator condition, hoses for leakage or damage, among others. To avoid overheating, fins of radiators should be cleaned.

- Spark Plug Inspection: Regularly examine spark plugs for replacement when needed. Cleaner spark plugs make engines more efficient during starting.

- Exhaust System Inspection: Do checks to ascertain whether there are holes, rusts or damages within your exhaust system structure. The muffler should be securely attached so that it serves its purpose adequately hence reducing noise levels.

- Load Testing: Under load conditions occasionally test-run generators to guarantee their correct operation under these circumstances; this helps forestall problems resulting from infrequent use.

- General Inspection: Always examine the generator to be sure of its performance. The thing is that you need to check if there are some places where the generator is worn out and other issues that need your concern. Fixing small issues can save the generator from breaking down.

These tips will help you take care of your Cummins generator by maintaining it at its best. Moreover, you can use these maintenance techniques as a means to enhance durability and efficiency of the engine that powers your home.

Common Oil-Related Issues and Troubleshooting

For the performance and lifespan of your Cummins generator, it is important to maintain the engine oil in good condition. But still, there can be some problems with oil. It is vital to know about these common oil-related difficulties and ways of their solution to keep your generator operating at its best.

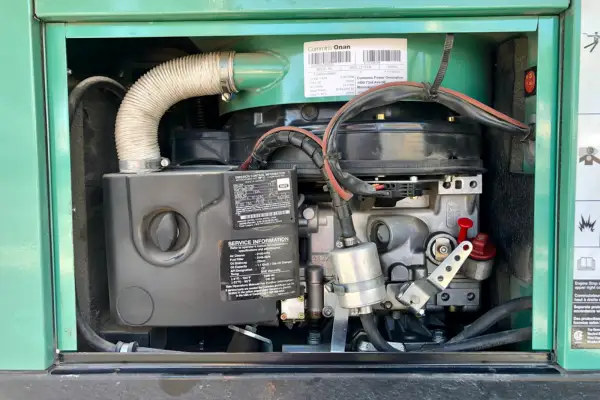

Identifying and Addressing Oil Leaks

Failure to address oil leaks may result into serious engine complications. Identifying sources of leaks promptly and mending them on time prevents further damages.

- Visual Inspection: Regularly check for any signs of oil leaks from your generator. Inspect the area near the generator casing for any sign of oil stains or the ground beneath the machine for puddles of oils.

- Check Seals and Gaskets: Oil often flows around seals and gaskets which eventually leak. Examine them properly looking out for signs of wear or damage. Any cracked, worn out or damaged seals or gaskets should be replaced.

- Tighten Connections: Loose drain plugs, oil filters or lines can sometimes create leakage problem in the generator that you use. All connections must be tight as well as secure enough but one care they should not be over tightened which may lead to breaking.

- Inspect Oil Filter: An improperly installed filter or one that is damaged can cause leakage. Ensure that you insert a new filter if this happens during an inspection.

- Engine Cleaning: Clean off any existing oil residues within the engine so that newer leakages become visible easily.

Symptoms of Using the Wrong Oil Type

Using wrong type of oils can bring many problems starting from loss in efficiency till extensive damage on engines. Knowing what symptoms are shown by using inappropriate lubricant will help you avoid more trouble when it’s not yet serious.

- Engine Overheating: In case there is inadequate lubrication provided by the used oils it leads to overheating up of an engine system which results in dramatic breakdowns; always consider checking whether the specified viscosity matches with its requirements as provided by Cummins.

- Excessive Smoke: An inappropriate oil can cause incomplete combustion of fuels leading to excess smoke coming out of the exhaust system. Confirm the oil type and quality in case you are noticing strange smoke from your generator’s engine.

- Increased Wear and Tear: The incorrect oil type may not provide enough lubrication, which causes more friction among parts of the engine hence accelerated wear. Always look for unusual wear on the engine system.

- Poor Performance: When very thick or thin oils are used in a machine, it may reduce its power and efficiency thus one should observe specific viscosity requirements. This implies that you should not use wrong viscosity oils when dealing with a motor.

- Oil Degradation: Unfit oils tend to break down much faster under normal engines running conditions resulting into sludge formation as well as loss of their lubricating properties. Periodically examine this liquid for any signs indicating its poor quality then change it if need be.

Steps to Rectify Oil-Related Problems

Rectifying issues related to oil on time can stop any further harm and keep your cummins generator working properly.

- Drain and Replace Oil: If you notice that different types of oils have been mixed, drain away all the present ones then replace them with a new one whose specifications were given by Cummins; make sure that the newly inserted fuel meets the supplier’s standards.

- Clean the Engine: A thorough cleaning exercise is needed where there is sludge or deposits due to wrong choice of oil. In such cases, use an engine flush before adding fresh oil in order to clean off dirt particles first.

- Replace Oil Filter: While changing oil filter, especially when wrong fuel has been put inside ensure it; so that no impurities are left behind after putting another set of filters into place always check whether they have been changed completely without being contaminated at all.

- Check and Repair Leaks: Ensure that any connections are tightened up well plus seals together with gaskets must be replaced if there is any oil leakage encountered and also confirm whether the filter is positioned properly to avoid more permeation of oil. Finally, keep observing for any other leaks after making the engine clean.

- Monitor Oil Levels and Quality: After addressing any issues, it’s a must to have regular checks for the level and quality of oil. Should there be signs of this oil being contaminated or degraded, change it.

- Consult the Manual: Always refer to the generator’s manual for specific maintenance guidelines and oil recommendations. To attain an ideal working condition, follow a guide from Cummins.

- Professional Service: If you encounter persistent oil-related problems or are unsure about how to address an issue, seek professional assistance. This includes diagnosis as well as repair that can only be done by authorized Cummins service centers.

By understanding common oil-related issues and knowing how to troubleshoot them, you can ensure that your Cummins generator remains in excellent working condition. Regular maintenance and prompt attention to problems will help extend the life of your generator and maintain its reliability.

Expert Advice and Resources

Leveraging expert advice and accessing the right resources can significantly enhance your understanding and maintenance of the Cummins generator. Cummins professionals offer invaluable insights, and there are numerous resources available to ensure you have the information and support you need.

Insights from Cummins Professionals

Cummins professionals provide a wealth of knowledge that can help you maintain and optimize the performance of your generator. Here are some key insights they offer:

- Regular Maintenance Schedules: Experts emphasize the importance of adhering to a regular maintenance schedule. This includes timely oil changes, filter replacements, and routine inspections to prevent potential issues and extend the lifespan of your generator.

- Correct Oil Usage: Using the right type and grade of oil is critical. Cummins professionals recommend using oils that meet Cummins’ specifications to ensure optimal performance and protection for your generator’s engine.

- Monitoring and Diagnostics: Keeping an eye on your generator’s performance indicators, such as oil pressure, temperature, and fuel levels, helps in early detection of potential issues. Cummins experts advise using diagnostic tools and software to monitor these parameters effectively.

- Load Management: Managing the load on your generator properly can prevent overloading and ensure efficient operation. Cummins professionals suggest balancing the load and avoiding sudden surges that could stress the engine.

- Training and Certification: For those responsible for maintaining multiple generators or commercial setups, Cummins offers training and certification programs. These programs provide in-depth knowledge and practical skills to maintain and troubleshoot Cummins generators effectively.

Frequently Asked Questions: Common Questions About Cummins Generator Oil Type

How often should my Cummins generator’s oil be changed?

The amount of times you change the oil is dependent on the kind of Cummins generator that you have and how it is used. Normally, it is appropriate to change your oil every 100-200 hours of running or at least once a year. Nonetheless, if your generator works in very harsh conditions or under heavy loads, this period may be shortened. Always check the machine’s manual as provided by the manufacturer for recommended durations between oil changes.

What kind of oil do I need in my Cummins generator?

Cummins generator recommend quality diesel engine oils with specific viscosity and performance characteristics. For instance, some common types include; SAE 15W-40, SAE 10W-30, and synthetic SAE 5W-40 oils. Thus, it is vital to choose an oil which meets their requirements such as API CK-4 or Cummins CES 20081 for ultimate motor protection and top performance. Therefore examine carefully all the required details concerning the right type of oil that your device requires in its manual guide.

Can I use Synthetics in my Cummins Generator?

Cummins generators can actually run on synthetic oils that are better in many ways than standard types. These oils are characterized by improved flow rate stability at different temperatures and pressures as well as extended intervals between maintenance services such as changing the fluids inside engines. For instance, SAE 5W-40 synthetic fluid has been recommended for those who own a Cummins generator that is exposed to harsh weather conditions or operates under heavy load.

What are the signs that I am using the wrong oil type in my generator?

Using the wrong oil type can lead to several issues, including:

- Engine Overheating: Inadequate lubrication can cause the engine to overheat.

- Excessive Smoke: Incorrect oil can result in incomplete combustion, producing more smoke.

- Increased Wear and Tear: Lack of proper lubrication can lead to premature wear of engine components.

- Poor Performance: Using oil with the wrong viscosity can affect the generator’s efficiency and power output.

- Oil Degradation: Incorrect oil may break down faster, leading to sludge formation and loss of lubrication properties.

How do I check the oil level in my Cummins generator?

To check the oil level in your Cummins generator:

- Ensure the generator is on a level surface and the engine is cool.

- Locate the dipstick, usually found on the side of the engine.

- Remove the dipstick, wipe it clean with a cloth, and reinsert it fully.

- Withdraw the dipstick again and check the oil level. The oil should be between the minimum and maximum marks on the dipstick.

- If the oil level is low, add the recommended oil type gradually, rechecking the level to avoid overfilling.

References

- The Cummins official website provides comprehensive information about their generators, including recommended oil types and maintenance guidelines.

- This resource offers detailed service information, including oil specifications for various Cummins generator models.

Cummins Oil Recommendations Manual

- This manual provides specific oil recommendations for Cummins engines, including viscosity grades and performance standards.