Cummins Inc. stands as a towering figure in the realm of power generation technology, celebrated for its robust and innovative engineering solutions that power a diverse range of applications worldwide. From small businesses to large industrial facilities, Cummins generators are pivotal in providing reliable energy solutions.

Understanding Cummins generator specifications extends far beyond simple power output. The specifications of a generator reveal much about its potential applications, efficiency, and operational cost, making it crucial for users to grasp these details to optimize performance and suitability for specific needs. This knowledge ensures that consumers can make informed decisions tailored to their unique power requirements, fostering a more efficient and effective use of technology in their operations.

In this article, we will navigate through various aspects of Cummins generators, offering insights into how these machines work, their benefits, and how to choose the right model for your needs. By exploring beyond mere power output, we aim to uncover the deeper qualities of these generators that make them stand out in a competitive market.

Understanding Key Specifications of Cummins Generators

When evaluating Cummins generator specifications, several key factors must be considered to ensure that the selected generator meets both performance expectations and application suitability. Here’s a deeper look into the primary specifications that define Cummins generators:

Wattage

The wattage of a generator indicates its power output capability, which is critical in determining how much electrical equipment it can support at once. Cummins generators range widely in wattage, accommodating everything from small-scale residential needs to large industrial demands. Understanding the wattage requirement is essential for selecting a generator that can handle your specific power loads without risk of overload.

Fuel Type and Efficiency

Cummins generators are available in various fuel types including diesel, gasoline, natural gas, and dual-fuel options, each offering distinct advantages. For instance:

- Diesel generators are celebrated for their durability and high energy yield per gallon of fuel, making them suitable for intense, long-duration use.

- Gasoline generators are typically more compact and cost-effective, ideal for temporary or less frequent applications.

- Natural Gas generators provide a cleaner burning option, reducing emissions and potentially lowering operating costs, depending on local gas prices.

- Dual-fuel capabilities allow greater flexibility in fuel choice and can be critical in areas where fuel supply may be inconsistent.

Efficiency

Efficiency in Cummins generators is measured by how effectively they convert fuel into electrical power. Higher efficiency not only means less fuel consumption but also reduced operating costs over the generator’s lifespan. Efficiency is influenced by factors like engine design, load management capabilities, and technological integrations such as automatic throttle adjustment which reduces fuel consumption during lower power demands.

These specifications not only impact the generator’s performance but also its suitability for different applications, ranging from residential emergency backups to continuous industrial use. By thoroughly understanding these key specifications, users can better align their power generation needs with the right Cummins generator, ensuring optimal performance and efficiency.

Fuel Types and Efficiency

The choice of fuel is a significant factor in the operation and efficiency of Cummins generators. Each fuel type offers unique benefits and impacts on operational costs differently. Here’s a detailed comparison of the various fuel options available for Cummins generators:

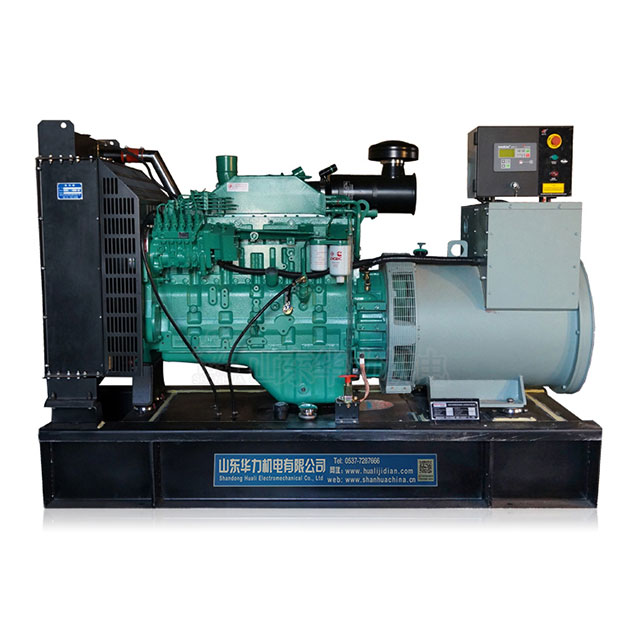

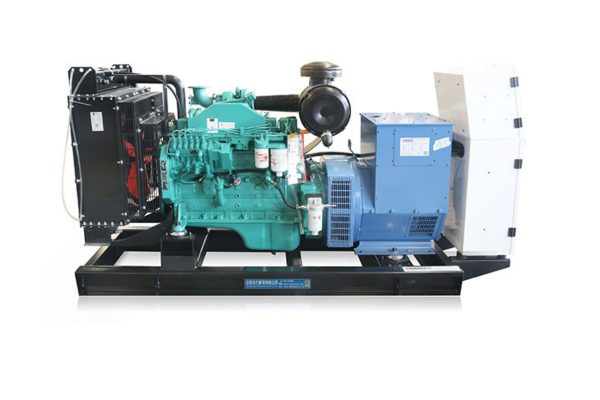

Diesel Generators

Diesel is the most commonly used fuel in heavy-duty generators due to its efficiency and durability. Cummins diesel generators are known for their robust performance and are capable of handling large loads over extended periods. They are highly efficient, with a better power-to-fuel consumption ratio, which makes them ideal for continuous operation, especially in industrial settings where reliability and longevity are critical.

Gasoline Generators

Gasoline-powered generators are generally less expensive and are preferred for portable or less frequent uses. While not as fuel-efficient as diesel, gasoline generators offer the convenience of easy availability of fuel and are typically lighter and more compact. They are well-suited for small businesses and residential emergency power backups where extensive runtime is not the primary requirement.

Natural Gas Generators

Natural gas generators are favored for their clean-burning properties, which result in lower emissions compared to diesel and gasoline. This makes them an environmentally friendlier option, contributing less to air pollution. Natural gas is also often less expensive than diesel and gasoline, depending on local fuel prices, which can significantly reduce operational costs. These generators are ideal for installations in environmentally sensitive areas and where noise levels are a concern, as they typically operate more quietly.

Hybrid Models

Cummins also offers hybrid models that can run on more than one type of fuel, providing flexibility in fuel choice and ensuring operation during fuel shortages. These generators can switch between fuel types like diesel and natural gas without shutting down, maintaining power supply during emergencies or fuel transitions.

Analysis of Fuel Efficiency

Fuel efficiency in Cummins generators not only affects the operational cost but also impacts the frequency and cost of refueling. Efficient fuel use in Cummins generators is enhanced by technologies such as turbocharging and aftercooling in diesel models, which optimize combustion and reduce waste. Additionally, features like Cummins’ PowerCommand® digital control systems manage engine operation to maintain optimal efficiency and performance across various loads and conditions.

Understanding these fuel types and their efficiencies is crucial for choosing the right Cummins generator that not only meets your power needs but also aligns with your operational cost goals and environmental considerations.

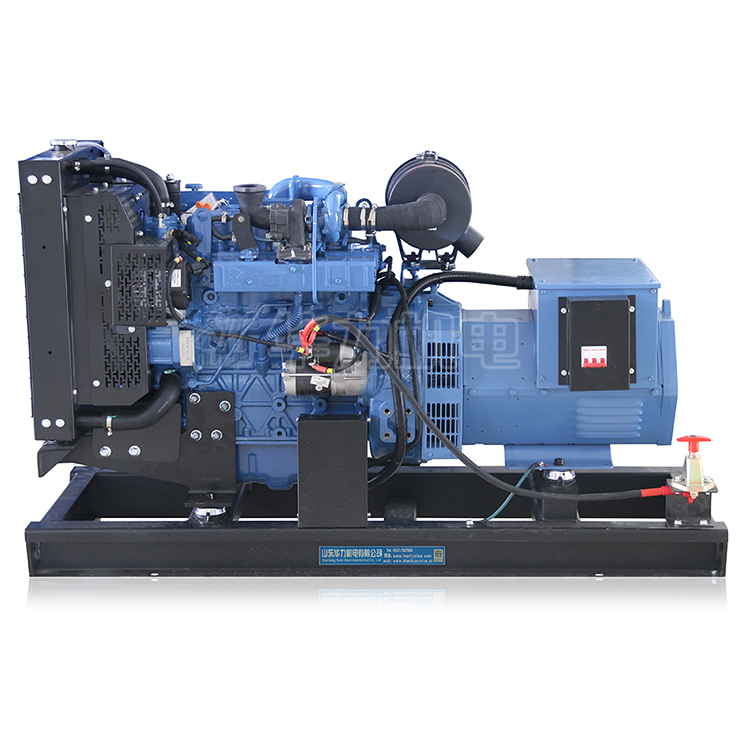

Size and Portability Considerations

Choosing the right Cummins generator involves more than just assessing power needs; size and portability are crucial factors, especially when space and mobility are constraints. Here’s how to select the appropriate size and model based on specific requirements:

Choosing the Right Size

The physical size of a generator is directly linked to its output capacity—larger generators typically produce more power. However, bigger isn’t always better. Choosing a generator that is too large for your needs can lead to inefficient operation and unnecessary fuel consumption. Conversely, a generator too small may not meet your energy demands, leading to potential overloads.

- Assess Your Space: Measure the area where you plan to install the generator. Ensure there is adequate space not only for the generator itself but also for maintenance access and ventilation.

- Consider Your Power Needs: Calculate the total wattage of the devices you need to power simultaneously. This will help determine the capacity of the generator you need without oversizing.

Portability Features

For applications requiring mobility, such as construction sites or outdoor events, the portability of a generator is a significant consideration.

- Built-in Wheels and Handles: Many Cummins portable generators come equipped with wheels and handles to facilitate easy movement. For instance, models designed for RV use or tailgating are often lightweight and feature telescoping handles that make them easy to transport and store.

- Weight Considerations: Portable generators vary in weight. Lighter models might offer less power but are easier to move. In contrast, high-capacity generators are heavier but often come with better handling features to compensate.

Impact of Size on Power Capacity

The size of a generator not only affects where it can be placed but also has implications for its power output and operational efficiency.

- Larger Generators: Typically have higher fuel capacities, allowing for extended run times. They are suitable for powering entire homes or large job sites where multiple high-wattage tools are used simultaneously.

- Smaller Generators: While they offer less power, their compact size makes them ideal for smaller applications, like powering individual appliances during a power outage or small tools at a job site.

When selecting a Cummins generator, it is essential to balance the need for power with the practicalities of space and portability. Consider how you plan to use the generator, where it will be stored, and whether you will need to move it frequently. This thoughtful consideration ensures that the generator you choose not only fits physically in your intended space but also meets your power needs efficiently without any logistical hassles.

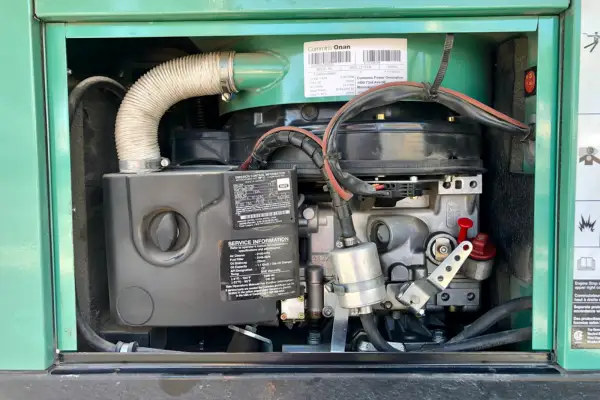

Technological Enhancements in Cummins Generators

Cummins is at the forefront of incorporating advanced technologies into their generators, significantly enhancing performance and convenience for users. Here’s a closer look at some of the key technological features found in Cummins generators:

Remote Monitoring

One of the most significant technological advances in Cummins generators is the ability to remotely monitor the system’s performance. This feature allows users to track the generator’s operation from a distance using a smartphone or computer. Remote monitoring is crucial for managing generators in hard-to-reach locations or in applications where continuous operation is critical. It helps in early detection of issues, ensuring timely maintenance and reducing downtime.

Automatic Transfer Switches

Automatic transfer switches (ATS) are integral to Cummins’ technology, providing seamless power transition in the event of an outage. When a power interruption is detected, the ATS automatically starts the generator, switching the power source from the utility to the generator without manual intervention. This is particularly important for critical environments like hospitals or data centers where power continuity is essential.

Inverter Technology

Cummins has integrated inverter technology into their portable generator lines, which allows for cleaner, more stable power output. This technology is essential for powering sensitive electronic devices such as computers, smartphones, and medical equipment, which require stable power to function correctly. Inverter generators adjust their engine speed to the load demand, which improves fuel efficiency and reduces noise levels.

Benefits of Integrating These Technologies

The integration of these advanced technologies in Cummins generators offers several benefits:

- Enhanced Performance: Technologies like inverter technology improve the generator’s efficiency and the quality of power it produces, making them suitable for a broader range of applications.

- Increased Convenience: Features like remote monitoring and automatic transfer switches enhance user convenience by automating operations and allowing easy management of the generator’s functions.

- Energy Efficiency: Advanced engine controls and inverter technology help in reducing fuel consumption, which is not only cost-effective but also environmentally friendly.

Cummins’ commitment to integrating advanced technologies into their generators ensures that they remain competitive and meet the evolving needs of modern users. These technological enhancements not only provide practical benefits but also contribute to the overall reliability and performance of the generators, making them a top choice for both residential and commercial applications.

Installation and Maintenance Tips

Proper installation and regular maintenance are crucial for maximizing the performance and longevity of your Cummins generator. Here are step-by-step tips for setting up your generator correctly and keeping it in optimal condition:

Installation Tips

- Selecting the Right Location: Choose a location that is both accessible for maintenance and safe for operation. It should be well-ventilated, dry, and away from any flammable materials. For outdoor installations, ensure the generator is elevated to avoid flood damage and has a protective enclosure to shield it from harsh weather.

- Ensure Proper Grounding and Stabilization: Proper grounding is crucial to avoid electrical shocks and ensure safe operation. Follow local codes for grounding generators. Additionally, make sure the generator is placed on a stable surface to minimize vibration, which can lead to mechanical wear over time.

- Connect to Fuel and Power Systems: For permanent installations, you may need professional help to connect the generator to your home’s fuel line and electrical system. Ensure all connections comply with local electrical codes and standards.

Maintenance Tips

- Regular Oil and Filter Changes: Just like any engine, your Cummins generator needs regular oil changes to keep running smoothly. Check the manufacturer’s guidelines for the recommended oil type and change intervals. Similarly, replace air and fuel filters as advised to ensure efficient operation.

- Inspect and Replace Spark Plugs and Belts: Regularly inspect spark plugs for wear and carbon build-up, which can affect engine efficiency. Replace them according to the service interval specified in your generator’s manual. Also, check belts for any signs of wear or damage, replacing them as needed.

- Battery Maintenance: If your generator has a battery for starting, ensure it is charged and in good condition. Check the battery terminals for corrosion and clean them if necessary. Regularly testing the battery will help you know when it’s time for a replacement.

- Run the Generator Regularly: Running your generator periodically not only ensures it’s ready for use when needed but also helps to keep the engine parts lubricated and to detect any issues that might need addressing. It is recommended to run your generator at least once a month for about 30 minutes.

- Professional Inspections: Have a professional technician inspect your generator annually. They can perform more complex checks and maintenance tasks, such as checking the alternator and the electrical output, ensuring your generator remains in top condition.

By following these installation and maintenance tips, you can significantly extend the life of your Cummins generator and ensure it provides reliable power when you need it most. Regular upkeep not only prevents breakdowns but also maintains the generator’s efficiency, making it a dependable power source for any application.

Case Studies and Real-World Applications

Cummins generators are utilized across various settings, showcasing their adaptability and robustness. Let’s explore how these generators perform in real-world applications through different case studies, demonstrating their impact on residential, commercial, and industrial settings.

Residential Use: Emergency Power Backup

In residential settings, Cummins generators often serve as critical backup power sources during outages. A notable case is in hurricane-prone areas where consistent power supply is a challenge. For instance, a family living in Florida relies on a Cummins residential generator to maintain power for essential appliances like refrigerators, air conditioning, and medical equipment during frequent storms. This application not only provides comfort but ensures safety and preserves quality of life during power interruptions.

Commercial Use: Construction Sites

Cummins generators are indispensable in commercial applications such as construction sites. These sites require reliable power for tools and machinery that cannot be connected to the main grid due to location or temporary setup. For example, a construction company utilized a Cummins portable generator to power an entire site in a remote area, facilitating the use of heavy machinery and lighting systems. This capability allowed the project to proceed on schedule without delays related to power supply issues.

Industrial Use: Manufacturing Facilities

In industrial environments, Cummins generators play a vital role in continuous manufacturing processes. A manufacturing plant may use a high-capacity Cummins generator as a standby power source to prevent downtime and protect sensitive equipment from damage caused by sudden power failures. One case involved a textile factory that installed a Cummins generator to ensure their production line remained operational 24/7, significantly reducing potential financial losses from halted production.

These case studies illustrate the critical role Cummins generators play across various sectors. By ensuring reliable and efficient power supply, these generators help mitigate risks associated with power outages, enhance operational efficiency, and support continuous productivity in demanding environments. Their ability to adapt to different operational scales and environments further solidifies their reputation as versatile and dependable power solutions.

Choosing the Right Cummins Generator for Your Needs

Selecting the appropriate Cummins generator requires a thorough assessment of your specific power needs, environmental conditions, and budget considerations. Here’s how to ensure you choose a generator that best fits your requirements:

Assess Your Power Needs

Begin by calculating the total wattage of the appliances and equipment you need to power. This includes understanding peak and continuous power requirements, as different devices have different starting and running wattage needs. Cummins offers a range of generators with varying power outputs, so identifying your exact needs will help you choose a model that neither underpowers nor wastes capacity.

Consider Environmental Conditions

The environment where the generator will operate influences the type of generator you should choose. For instance, if you’re in a region with stringent emissions regulations, a natural gas or low-emission diesel model from Cummins might be appropriate. Similarly, if noise is a concern, such as in residential areas or hospitals, selecting from Cummins’ line of quiet generators will ensure compliance and reduce disturbance.

Budget Considerations

While initial purchase price is a factor, consider the total cost of ownership, which includes maintenance, fuel consumption, and potential downtime costs. Cummins generators are known for their durability and efficiency, but choosing a model that balances upfront costs with operational expenses is crucial for long-term satisfaction.

Resources and Purchasing Options

Cummins generators can be purchased through authorized dealers, which can be found on their official website. Additionally, some models are available for direct purchase online. It’s advisable to consult with a Cummins certified dealer who can provide expert advice tailored to your specific needs and help facilitate the purchase and installation process.

By carefully considering these factors, you can choose a Cummins generator that not only meets your current power requirements but also adapts to future needs, ensuring reliable power delivery and operational efficiency for years to come.

FAQs: Common Questions About Cummins Generator Specifications

When exploring Cummins generators, potential users often have a range of questions regarding their specifications, operation, and best practices. Here are some frequently asked questions that can help clarify common queries about Cummins generator specifications:

What Are the Typical Fuel Options for Cummins Generators?

Cummins generators typically offer several fuel options, including diesel, natural gas, and propane, with some models offering flexibility through dual-fuel capabilities. The choice of fuel impacts the generator’s application, efficiency, and operational costs.

How Do I Determine the Right Size Generator for My Needs?

To select the appropriate size for a Cummins generator, calculate the total wattage of all appliances and equipment you plan to run simultaneously. This will guide you to a generator that can handle the load without being oversized, which can be inefficient and costly.

Can Cummins Generators Run Continuously?

Yes, many Cummins generators are designed for continuous operation, especially models geared towards industrial and commercial use. However, the operational capacity can vary based on the model and the specific setup, so it’s crucial to consult specific product documentation for precise capabilities.

What Is the Lifespan of a Cummins Generator?

The lifespan of a Cummins generator depends on several factors, including usage, maintenance, and environmental conditions. With proper maintenance, Cummins generators can operate reliably for many years.

Are Cummins Generators Weatherproof?

Cummins offers models with weatherproof enclosures that are designed to withstand harsh environmental conditions. These are particularly useful in outdoor installations where the generator is exposed to elements like rain, snow, and extreme temperatures.

How Often Should Maintenance Be Performed on a Cummins Generator?

Regular maintenance is key to the longevity and reliability of any generator. Cummins recommends checking the owner’s manual for specific maintenance schedules, but general practices include regular oil and filter changes, checking and cleaning air filters, and ensuring the unit is run periodically to keep mechanical parts lubricated.

References

Cummins diesel generators are recognized for their reliability and performance, with power outputs ranging from 15 to 3,750 kVA. The generators are available in models suitable for different fuel types, including diesel, natural gas, and renewable options like Hydrotreated Vegetable Oil (HVO)

Specific models, such as the QSK95 series, feature a cast iron, V16 cylinder configuration with a displacement of 95.3 liters, highlighting their substantial power capabilities. These generators are equipped with advanced fuel systems and comprehensive cooling solutions, making them suitable for heavy-duty applications

Cummins also provides detailed spec sheets for individual models, which include information on power output, fuel type, and engine specifications. For example, the C3000 series offers models with various kW/kVA ratings for different applications like continuous, prime, and standby power