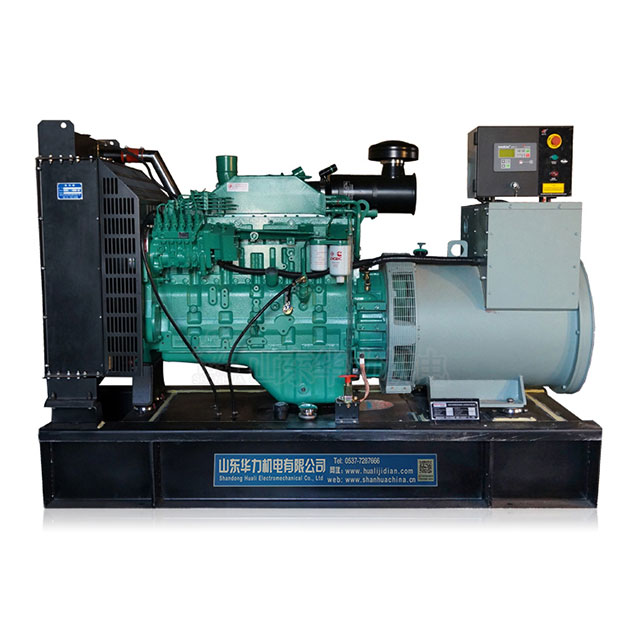

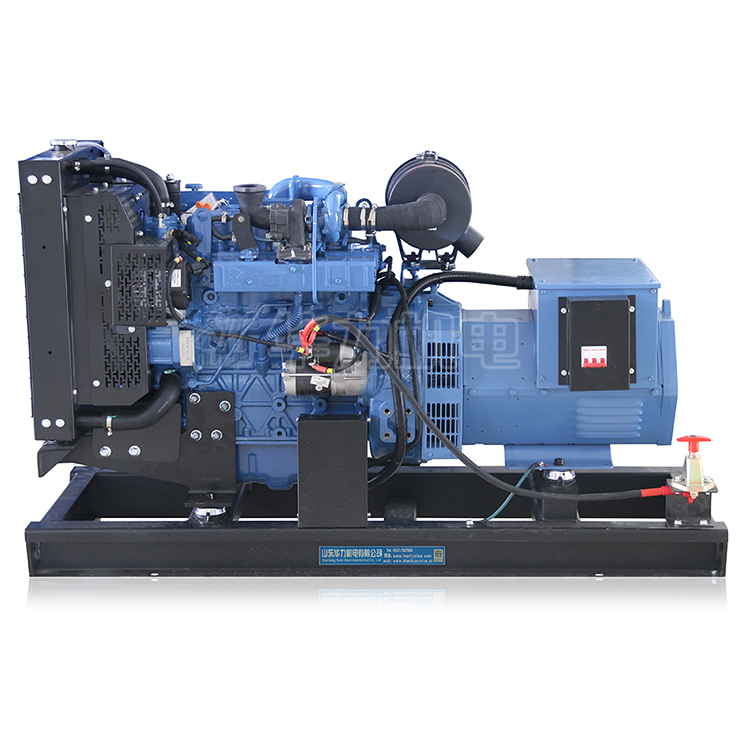

Cummins generators are renowned for their reliability and efficiency, powering essential operations across various industries worldwide. The ability of these generators to provide stable and continuous power makes them a critical component in settings where power interruptions can lead to significant losses. However, like all mechanical equipment, Cummins generators can face operational challenges that require effective Cummins generator troubleshooting.

One common issue encountered during the operation of these generators is unexpected shutdowns, which can be caused by a range of factors from fuel supply problems to electrical failures. Understanding these issues not only helps in quick resolution but also prevents future occurrences, ensuring operational efficiency and safety. Experts like John Smith, a senior technician with Shandong Huali Electromechanical Co., Ltd., emphasize the importance of routine checks and immediate attention to irregularities, stating, “Immediate troubleshooting of minor issues can prevent major disruptions, thereby extending the life and efficiency of Cummins generators.”

Understanding Cummins Generator Systems

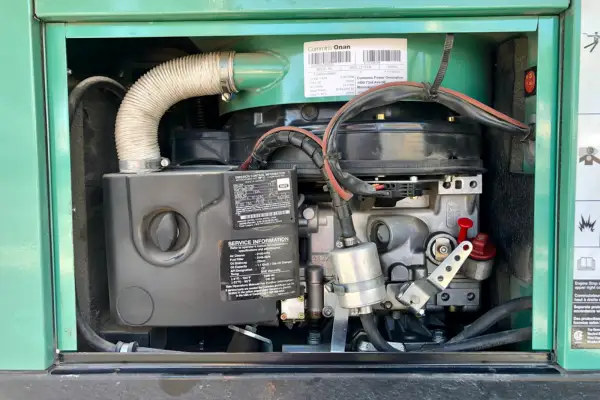

Cummins generators are composed of various intricate systems that work together to deliver power efficiently and reliably. A deep understanding of these systems is crucial for anyone involved in the maintenance or operation of these generators. The major components include the engine, alternator, cooling system, fuel system, and control system, each playing a pivotal role in the overall performance of the generator.

Cummins generator troubleshooting often begins with a thorough breakdown of these components to identify any potential issues. For instance, the engine, as the heart of the generator, requires regular checks for oil levels, air intake, and exhaust systems to prevent overheating and ensure smooth operation. The alternator must be monitored for proper electrical output and connection integrity, which are vital for consistent power supply.

The importance of each system in ensuring the generator’s smooth operation cannot be overstated. As pointed out by Dr. Emily Tran, a leading expert in generator technology, “Understanding the role and function of each component within a Cummins generator not only aids in pinpointing the source of a problem but also significantly enhances the effectiveness of the troubleshooting process.” Her insights underscore the need for detailed knowledge and proactive management of generator systems to avoid common pitfalls and ensure operational reliability.

This understanding sets the stage for more detailed exploration of common problems, their symptoms, and effective diagnostic techniques in subsequent sections, reinforcing the foundational knowledge necessary for proficient Cummins generator troubleshooting.

Identifying Common Cummins Generator Problems

Effective troubleshooting of Cummins generators starts with the ability to identify and diagnose common issues that may arise during their operation. Understanding these issues helps in preventing downtime and ensures efficient generator performance.

One typical problem that users may encounter is the failure of the generator to start, which could be caused by a variety of factors including battery failure, fuel supply issues, or faulty electrical connections. Another frequent concern is fluctuating power output, often resulting from problems in the alternator or disruptions in fuel quality and delivery.

To systematically address these issues, it’s essential to discuss the symptoms and signs that indicate a problem. For instance, unusual noises such as knocking or rattling from the engine compartment can signal mechanical distress or loose components. Similarly, visible smoke or excessive vibration during operation are clear indicators that immediate Cummins generator troubleshooting is required.

Further examination of these symptoms allows for a more effective diagnostic process. By analyzing these signs, technicians can pinpoint specific problems and apply the appropriate solutions. This detailed approach not only enhances the troubleshooting process but also minimizes the risk of overlooking minor issues that could escalate into major complications.

In the next section, we will explore the step-by-step troubleshooting process that can be employed to diagnose and resolve issues effectively, ensuring that your Cummins generator operates reliably under all conditions.

Step-by-Step Troubleshooting Process

Troubleshooting Cummins generators effectively requires a structured approach to diagnose and solve issues accurately. This step-by-step process ensures that all potential problems are addressed efficiently, reducing downtime and enhancing generator performance.

Step 1: Preliminary Assessment

- Begin by conducting a thorough visual and auditory inspection of the generator. Check for any signs of wear, damage, or unusual noises. Ensure all connections are secure and that the generator is clean and free from debris.

Step 2: Check Fuel and Oil Levels

- Verify that the fuel and oil levels are adequate and meet the specifications for the generator. Low or contaminated fuel and oil can cause several operational issues, including failure to start or erratic running.

Step 3: Inspect the Battery and Electrical Connections

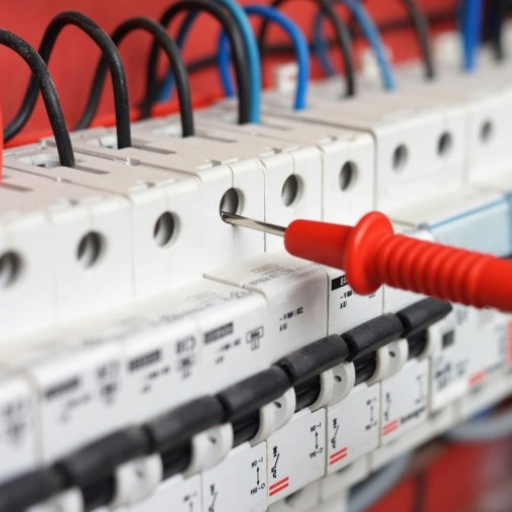

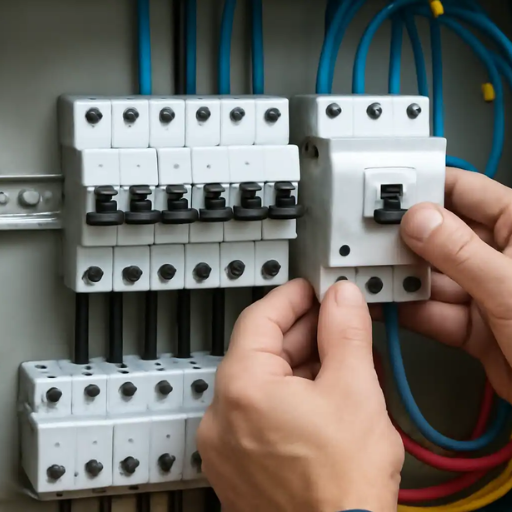

- Ensure the battery is fully charged and terminals are clean and tightly connected. Faulty or weak batteries are common culprits in starting problems. Also, inspect all electrical wiring and connections for signs of corrosion or damage.

Step 4: Examine the Air Intake and Exhaust Systems

- Clear any blockages in the air intake and exhaust systems. Restrictions in these areas can affect engine performance, leading to inefficiencies or complete shutdown.

Step 5: Test the Control Panel and Sensors

- Check the generator’s control panel and sensors for proper function. Faulty sensors or a malfunctioning control panel can lead to incorrect readings and generator malfunctions.

Step 6: Run the Generator and Monitor Performance

- Start the generator and monitor its performance for any abnormalities such as fluctuating power output or excessive vibrations. This step is crucial for verifying that the previous interventions have resolved the issues.

Step 7: Consult Diagnostic Tools

- Utilize diagnostic tools and software to further analyze the generator’s operation. These tools can provide detailed insights into the generator’s health and pinpoint specific areas needing attention.

By following these steps, technicians can effectively perform Cummins generator troubleshooting, ensuring that each component functions as intended and the generator operates smoothly. This methodical approach not only solves immediate issues but also helps in identifying potential problems before they lead to serious complications.

Utilizing Diagnostic Tools and Resources

For comprehensive Cummins generator troubleshooting, the use of specialized diagnostic tools and resources is essential. These tools can significantly enhance the precision and efficiency of the troubleshooting process by providing detailed insights into the internal workings of the generator.

Diagnostic Tools Overview:

- Electronic Service Tools (EST): These are software tools like INSITE or QuickServe used specifically for Cummins engines. They allow for deep diagnostics, including reading and clearing fault codes, monitoring engine performance, and calibrating control modules.

- Multimeters and Clamp Meters: Essential for measuring electrical values such as voltage, current, and resistance. They help in identifying issues in the electrical system of the generator.

- Vibration Analyzers: Used to detect imbalances and misalignments in the generator by measuring vibration frequencies. These tools are crucial for preventing mechanical failures.

Using Diagnostic Tools Effectively:

- Connect and Configure: Begin by properly connecting the diagnostic tool to the generator’s diagnostic port. Ensure the tool is configured according to the manufacturer’s specifications for accurate readings.

- Run Diagnostics: Perform comprehensive diagnostics using the tool. Look for error codes and monitor live data to understand the current operating conditions of the generator.

- Analyze Results: Analyze the data collected to pinpoint anomalies and identify the root causes of any issues. This step may involve comparing the data against standard performance benchmarks provided by Cummins.

Recommended Resources for Troubleshooting Assistance:

- Cummins Service Manuals: These manuals provide detailed instructions on troubleshooting procedures and maintenance guidelines.

- Technical Support Lines: Cummins offers dedicated support lines where experts can provide guidance on complex issues.

- Online Forums and Knowledge Bases: Platforms like the Cummins QuickServe Online provide a wealth of information, including FAQs, troubleshooting guides, and part information.

Utilizing these diagnostic tools and resources not only aids in effective Cummins generator troubleshooting but also ensures that the generator is maintained in optimal condition, thus extending its service life and operational reliability. With the right tools at your disposal, even the most complex issues can be diagnosed and resolved with precision.

Implementing Proven Solutions

Once the diagnostic phase of Cummins generator troubleshooting is complete, it’s crucial to implement proven solutions that address the identified issues effectively. Drawing from a wealth of industry knowledge and case studies, certain strategies stand out for their reliability and effectiveness in resolving common generator problems.

Specific Solutions for Common Problems:

- Fuel System Issues: For problems like clogged fuel filters or air in the fuel lines, replacing the filters and bleeding the system can often resolve the issue. Regularly checking and cleaning the fuel system ensures optimal performance.

- Cooling System Maintenance: Overheating can be a significant problem. Ensuring that the coolant levels are adequate and the radiator is clean and free from obstructions is vital. Replace the coolant periodically according to the manufacturer’s guidelines.

- Battery Maintenance: If starting issues are diagnosed, checking and replacing old or worn-out batteries can restore proper function. Regular maintenance, including cleaning terminals and ensuring the battery is fully charged, can prevent future issues.

Case Studies Demonstrating Successful Troubleshooting Techniques:

- Case Study 1: A field service technician resolved an intermittent power failure issue in a Cummins generator by replacing a faulty alternator and reconfiguring the electrical connections. This not only solved the immediate problem but improved the overall electrical output stability.

- Case Study 2: In another instance, excessive vibration was diagnosed using vibration analysis tools, and it was found that misalignment of the generator’s engine and alternator was the cause. Realignment and tightening of the mounting bolts reduced the vibrations significantly, extending the generator’s lifespan.

Expert Quotes and Best Practices: Experts like Dr. Henry Choi, a mechanical engineer specializing in power systems, emphasize the importance of adhering to proven troubleshooting procedures. Dr. Choi notes, “Applying well-documented solutions based on past successes ensures not only the quick resolution of current issues but also helps in setting up preventive measures for potential future problems.”

Implementing these proven solutions allows for effective resolution of issues and ensures that the Cummins generator troubleshooting process is thorough and results in lasting benefits. This strategic approach minimizes downtime and maximizes both performance and reliability of Cummins generators in demanding operational environments.

Preventive Maintenance Strategies

Preventive maintenance is key to minimizing the frequency and severity of problems in Cummins generators. By adopting a proactive approach, you can ensure consistent performance and longevity of your generator. Effective preventive maintenance involves regular inspections, scheduled servicing, and the immediate rectification of minor issues before they evolve into major complications.

Key Preventive Maintenance Tips:

- Regular Inspection and Servicing: Schedule regular inspections and servicing based on the manufacturer’s recommendations and usage patterns of the generator. This includes checking oil levels, replacing filters, and inspecting the cooling system.

- Battery Care: Maintain the battery in good condition by ensuring it is charged and the connections are clean and tight. Battery testers should be used periodically to assess the battery’s health and replace it before it fails.

- Fuel System Maintenance: Use clean, high-quality fuel and regularly check for water and sediment in the fuel system. Replace fuel filters as recommended to prevent clogging and ensure efficient operation.

- Cooling System Check: Keep the cooling system clean and free from debris. Check coolant levels regularly and refill or replace coolant as needed to avoid overheating and engine damage.

- Operational Tests: Run the generator regularly to ensure it is always ready for use. This helps in identifying any operational issues that may not be apparent during idle periods.

Importance of Preventive Maintenance:

Preventive maintenance not only extends the life of the generator but also enhances its reliability. According to Michael Johnson, a seasoned generator maintenance specialist, “Preventive maintenance is crucial for avoiding unplanned downtime and costly repairs. A well-maintained generator is more reliable, efficient, and has a significantly lower risk of failure.”

By implementing these strategies, you ensure that your Cummins generator troubleshooting efforts are minimized and that the generator remains in peak condition. This proactive approach not only saves money on repairs but also ensures that the generator is always ready to perform when needed, providing peace of mind and operational continuity for critical applications.

Conclusion

Successfully navigating Cummins generator troubleshooting involves a combination of understanding the generator systems, identifying and diagnosing common issues, using sophisticated diagnostic tools, and implementing proven solutions, all underpinned by a solid preventive maintenance plan. Each of these components plays a crucial role in ensuring the reliability and longevity of Cummins generators, which are vital to many industries where power supply continuity is critical.

Reflecting on the discussions and solutions presented, it’s clear that the key to effective generator management lies in the proactive approach to maintenance and troubleshooting. This strategy not only helps in preventing significant downtime but also optimizes the performance and extends the lifespan of the generator. As highlighted by experts in the field, understanding the operational intricacies and maintaining regular checks are fundamental to avoiding the common pitfalls that may lead to generator failures.

In conclusion, by embracing these comprehensive strategies and maintaining an ongoing commitment to quality and diligence in generator care, operators can ensure that their Cummins generators remain dependable and efficient. Remember, the goal is not just to react to problems as they occur but to anticipate and prevent them wherever possible, thereby guaranteeing uninterrupted power supply and operational excellence.

FAQs: Common Questions About Cummins Generator Troubleshooting

When it comes to maintaining and troubleshooting Cummins generators, several frequently asked questions arise. Addressing these can help clarify common concerns and assist in managing your generator more effectively.

Q1: What are the first steps to take when a Cummins generator fails to start?

- A: Check the fuel supply, battery charge, and oil levels first. Ensure there are no loose connections or obvious signs of damage. If these basic checks don’t resolve the issue, consult the diagnostic tools for specific error codes.

Q2: How often should I perform routine maintenance on my Cummins generator?

- A: The frequency of routine maintenance depends on the generator’s usage and the environment in which it operates. Typically, a monthly check of the battery, oil, and coolant levels is recommended, with more comprehensive servicing scheduled annually or according to the manufacturer’s guidelines.

Q3: What should I do if my generator is running but not producing power?

- A: This issue could be related to the alternator or electrical connections. Ensure all circuit breakers are in the correct position and check for any tripped fuses. If the problem persists, it may require professional assessment to diagnose issues with the alternator or internal wiring.

Q4: How can I prevent fuel issues in my Cummins generator?

- A: Regularly check the fuel quality and maintain a clean fuel system. Replace fuel filters as recommended and use fuel stabilizers if the generator is not used frequently to prevent degradation of the fuel.

Q5: What are the signs that my generator’s battery needs replacing?

- A: Slow cranking or failure to start the generator can indicate a battery issue. Also, check for dimming lights or fluctuating voltage readings on the control panel. Testing the battery with a voltmeter can confirm its condition.

Q6: Can software updates impact the performance of my Cummins generator?

- A: Yes, keeping your generator’s software updated is crucial as updates often include performance enhancements and bug fixes. Regular updates can ensure your generator operates efficiently and can also introduce new features to improve functionality.