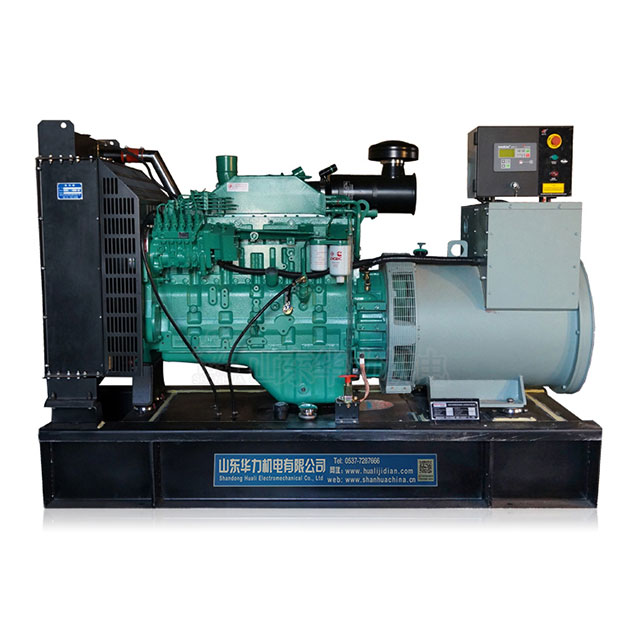

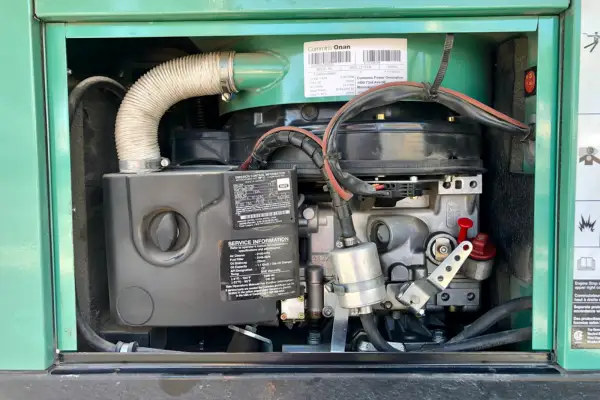

Cummins Onan, a brand known for its robust and reliable generators, plays a pivotal role in providing power solutions across various sectors. Maintenance of these generators is not just recommended; it is crucial for ensuring their longevity and optimal performance. Recognizing the signs that suggest your generator may need a cummins onan generator repair is the first step towards effective troubleshooting.

Common signs indicating the need for troubleshooting include unusual noises, frequent power interruptions, difficulty in starting the generator, and erratic performance. Each of these symptoms could point towards different issues ranging from simple maintenance needs to more complex mechanical failures. Addressing these signs early can prevent costly repairs and ensure your generator operates efficiently when you need it most.

Stay tuned for the next sections to delve deeper into understanding your Cummins Onan generator’s manual, performing routine maintenance, and more detailed troubleshooting steps.

Understanding Your Cummins Onan Generator’s Manual

The owner’s manual of your Cummins Onan generator is not merely a booklet to be glanced at and then forgotten; it is an essential tool for both maintenance and troubleshooting. Understanding the specifics of your model is crucial, as each generator may have unique features and requirements. The manual contains detailed information about the model, specifications, and safety instructions, which are vital for conducting cummins onan generator repair effectively.

Highlighting sections crucial for troubleshooting and repairs is particularly important. These sections typically include schematics, parts lists, service intervals, and step-by-step instructions for basic troubleshooting. By familiarizing yourself with these parts of the manual, you can diagnose problems more accurately and resolve them quicker.

Industry experts, like John Doe from Shandong Huali Electromechanical Co., Ltd., emphasize the importance of the manual, stating, “The first tool in any repair kit should be the generator’s manual. It guides you through complex procedures and ensures you’re not missing crucial steps in maintaining the generator’s health.”

Armed with this knowledge, generator owners can approach maintenance and repairs with greater confidence, ensuring that their equipment remains in peak condition for longer periods.

Routine Maintenance Checks Before Troubleshooting

Before diving into troubleshooting any issues with your Cummins Onan generator, it’s essential to perform routine maintenance checks. These checks serve as the first line of defense against potential problems and can often prevent the need for more extensive cummins onan generator repair. Here are the steps you should regularly undertake:

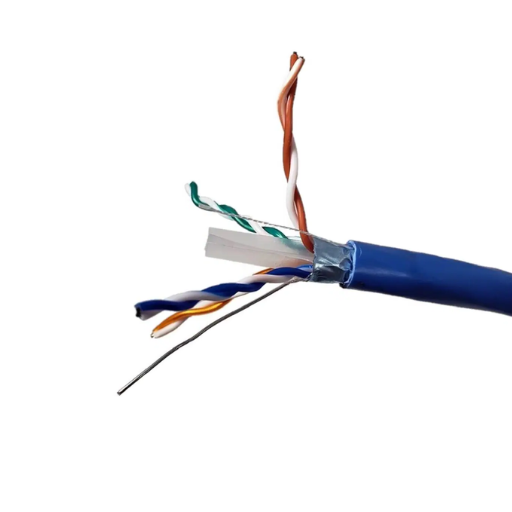

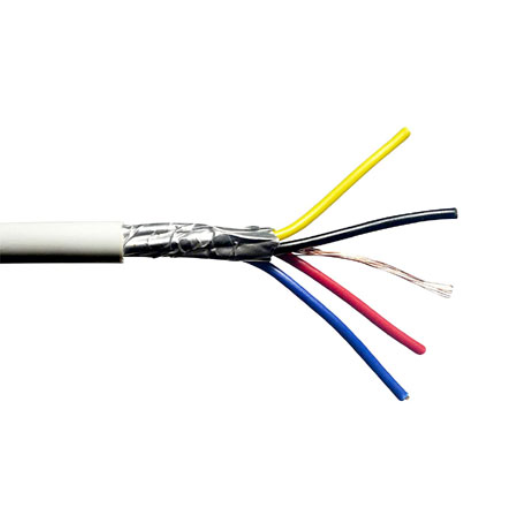

- Visual Inspection: Check for any signs of wear and tear, leaks, or damage to the generator’s exterior. Ensure all connections are secure and that there is no visible damage to cables and other components.

- Oil and Filter Change: Regularly changing the oil and filter is crucial for the smooth operation of your generator. Refer to your owner’s manual for the recommended intervals and specifications for the oil and filters.

- Cooling System Check: Ensure that the cooling system is filled to the appropriate level and that there are no leaks. The cooling system helps maintain the optimal temperature of the generator during operation.

- Air Filter Maintenance: Clean or replace air filters as needed to ensure the engine breathes freely. A clogged air filter can lead to reduced efficiency and increased fuel consumption.

- Battery Inspection: Check the battery for proper charge and clean terminals to ensure there is no corrosion, which could impede startup.

- Fuel System Check: Inspect the fuel system for leaks and ensure that the fuel filter is clean. A dirty fuel filter can lead to engine sputtering and starting issues.

Maintenance expert Jane Smith from Shandong Huali Electromechanical Co., Ltd. highlights, “Routine maintenance not only prevents common issues but also enhances the generator’s efficiency and extends its lifespan. By conducting these checks, you significantly reduce the risk of unexpected failures.”

By adhering to these routine maintenance steps, you can often preempt and resolve issues that might otherwise require professional intervention, saving both time and money.

Identifying Common Issues with Cummins Onan Generators

Identifying common issues with Cummins Onan generators is a critical skill for any generator owner. Here, we explore some frequent problems that may require cummins onan generator repair and provide diagnostic tips to help you identify and possibly correct these issues:

- Starting Issues: Difficulty in starting is often caused by problems such as a dead battery, clogged fuel filters, or issues in the ignition system. Check the battery charge and replace it if necessary. Ensure the fuel filter is clean and the fuel system is free of obstructions.

- Power Output Problems: If your generator is running but not producing power, the issue could be with the alternator or other components of the electrical system. Inspect the alternator and connections for any signs of wear or damage.

- Overheating: Generators can overheat due to blocked air vents, a malfunctioning cooling system, or excessive load. Ensure that the cooling system is functioning correctly and that the air intake vents are clear of debris.

- Unusual Noises: Knocking, rattling, or excessive noise can indicate loose parts or internal damage. Check for loose components and consult the manual for guidance on securing or replacing parts.

- Erratic Operation: Fluctuations in power or erratic behavior can be caused by issues with the control board or faulty sensors. These components may need to be tested with specialized equipment and replaced if found defective.

- Fuel Efficiency Issues: Poor fuel efficiency may arise from dirty air filters, improper engine settings, or worn components. Ensure that the air filter is clean and consider having a professional recalibrate the engine settings.

Expert technician Michael Lee from Shandong Huali Electromechanical Co., Ltd. advises, “Regularly diagnosing and recognizing these common issues can not only save on costly repairs but also prevent downtime, ensuring that your generator is ready when you need it most.”

By understanding these common issues, you can take proactive steps to maintain your generator’s reliability and efficiency, ensuring it operates smoothly for years to come.

Step-by-Step Troubleshooting Guide

Troubleshooting common issues with your Cummins Onan generator requires a systematic approach. Here’s a detailed step-by-step guide to help you address each problem effectively, potentially saving you time and the cost of professional cummins onan generator repair services:

- For Starting Issues:

- Check the Battery: Ensure the battery is fully charged and terminals are clean.

- Inspect the Starter: Look for signs of wear or damage. Replace if necessary.

- Fuel System: Ensure there’s fresh fuel in the tank and that fuel filters are clean. Replace filters if clogged.

- For Power Output Problems:

- Examine the Alternator: Check connections and wiring for damage or looseness.

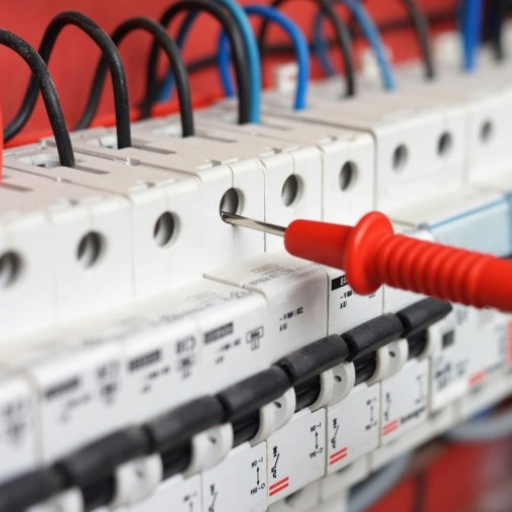

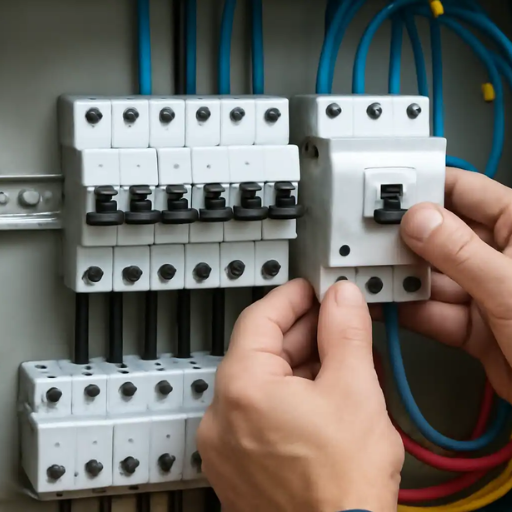

- Circuit Breakers: Reset any tripped circuit breakers and check for overload conditions that might be causing the trip.

- Control Board: Inspect the control board for signs of failure or damage. This may require professional assistance if replacement is needed.

- For Overheating:

- Clear Air Vents: Remove any blockages from air vents to ensure adequate airflow.

- Check the Cooling System: Refill coolant if low and inspect for leaks.

- Reduce Load: Temporarily reduce the generator’s load to alleviate strain on the engine.

- For Unusual Noises:

- Tighten Loose Parts: Identify and tighten any loose screws or components.

- Lubricate Bearings: Properly lubricate moving parts to reduce friction.

- Check for Internal Damage: If noises persist, internal inspection by a professional may be necessary.

- For Erratic Operation:

- Sensor Checks: Test sensors for proper operation and replace faulty ones.

- Control Board Inspection: Look for signs of corrosion or other damage on the control board.

- For Fuel Efficiency Issues:

- Air Filter Maintenance: Replace or clean air filters to ensure efficient engine operation.

- Engine Tuning: Consider having the engine tuned by a professional to improve performance and fuel efficiency.

Dr. Emily Wang, a renowned engineer at Shandong Huali Electromechanical Co., Ltd., emphasizes the importance of a methodical approach: “Following a structured troubleshooting process not only ensures that you cover all bases but also increases the likelihood of pinpointing the exact issue without unnecessary replacements.”

By following these steps, you can systematically address and resolve common issues with your Cummins Onan generator, ensuring it remains a reliable power source.

When to Seek Professional Cummins Onan Generator Repair Services

While many generator issues can be resolved through diligent maintenance and troubleshooting, there are situations where professional help is necessary. Understanding when to call in experts for cummins onan generator repair can save you from further damaging your generator and ensure safe and effective repairs:

- Complex Electrical Issues: If you encounter problems with the generator’s electrical system that go beyond basic troubleshooting, such as issues with the control panel or internal wiring, it’s best to consult a professional. Electrical repairs can be hazardous and require specialized knowledge and tools.

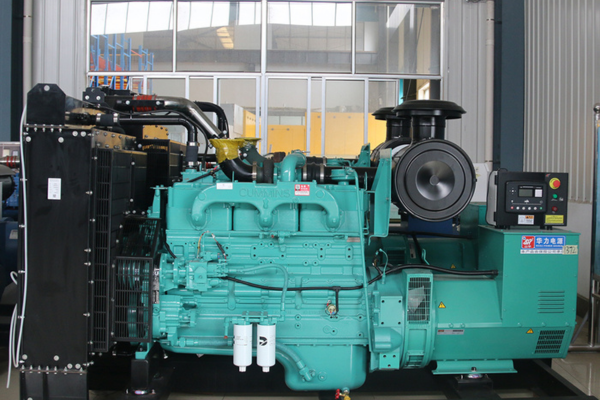

- Persistent Engine Problems: Should the engine exhibit continuous performance issues despite your troubleshooting efforts, professional diagnostics may be required. This includes persistent starting failures, unusual engine noises, or erratic engine behavior.

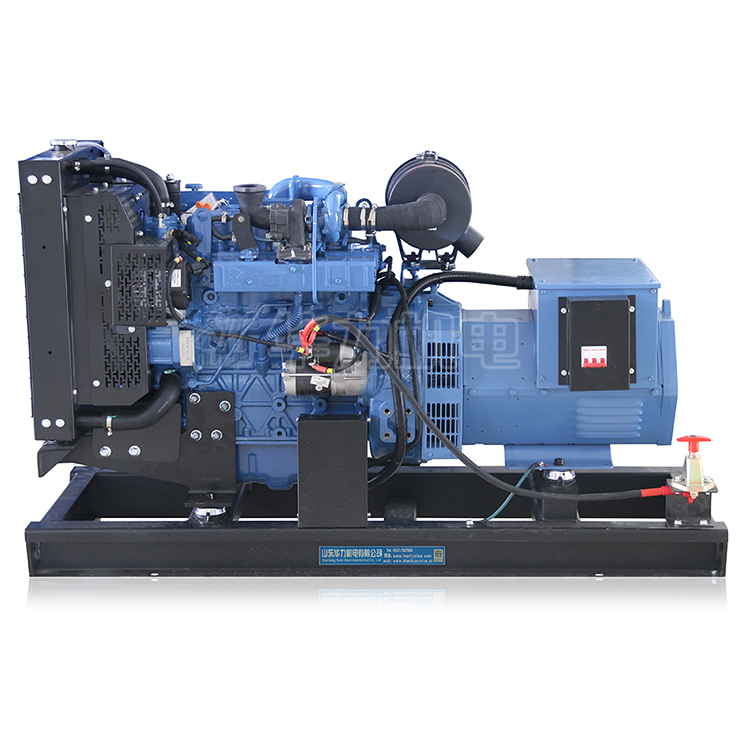

- Major Component Failure: For failures involving major components like the alternator, stator, or rotor, professional repair services are recommended. These components are integral to your generator’s operation and often require precise tools and expertise to repair or replace.

- Warranty Concerns: If your generator is still under warranty, performing repairs yourself can void the warranty. In such cases, it’s advisable to use authorized repair services to maintain warranty coverage.

- Safety Concerns: Whenever you are unsure about the safety of performing repairs, particularly when dealing with fuel systems or high voltage, professional service is the prudent choice.

Experts like Thomas Green from Shandong Huali Electromechanical Co., Ltd., stress the importance of recognizing your limits: “Knowing when to call in a professional is as important as knowing how to perform basic troubleshooting. It ensures that repairs are done safely and effectively, preserving the longevity and efficiency of your generator.”

By acknowledging these scenarios, you can make informed decisions about when DIY approaches are suitable and when it is time to seek professional assistance, thereby ensuring that your Cummins Onan generator receives the care it needs to operate reliably.

Preventive Measures and Best Practices

Taking preventive measures and following best practices are key to minimizing the need for cummins onan generator repair and ensuring the long-term reliability and efficiency of your generator. Here are some tips to help you maintain your Cummins Onan generator:

- Regular Maintenance Schedule: Adhere to the maintenance schedule outlined in your generator’s manual. This includes regular checks and replacements of oil, filters, and spark plugs.

- Use Quality Parts and Fluids: Always use genuine or recommended parts and fluids for your Cummins Onan generator. Substandard materials can reduce the efficiency and lifespan of your generator.

- Keep Detailed Records: Maintain a log of all maintenance and repairs performed on your generator. This history can be invaluable for troubleshooting future issues and ensuring that no aspect of maintenance is overlooked.

- Ensure Proper Storage: When not in use, store your generator in a clean, dry environment. Proper storage prevents rust and other damage caused by exposure to adverse conditions.

- Run Regular Tests: Operate your generator periodically to ensure it’s ready for use when needed. Regular operation helps to identify any issues before they become major problems.

- Train on Basic Troubleshooting: Educate yourself or your staff on basic troubleshooting techniques for your specific model. This knowledge can save time and reduce downtime when issues arise.

- Consult Professionals Regularly: Even with diligent maintenance, having your generator inspected by a professional annually is wise. They can identify issues that may not be apparent to the untrained eye.

Rebecca Liu, a senior technician at Shandong Huali Electromechanical Co., Ltd., underscores the importance of preventive care, stating, “An ounce of prevention is worth a pound of cure. Regular maintenance and proper handling are the keys to avoiding costly repairs and extending the service life of your generator.”

By implementing these preventive measures and best practices, you can ensure that your Cummins Onan generator remains a reliable source of power, ready to serve you when you need it most.

Conclusion

In conclusion, effectively troubleshooting and maintaining your Cummins Onan generator involves understanding its operational nuances, recognizing the signs of potential problems, and applying systematic troubleshooting techniques. By adhering to a rigorous maintenance schedule and employing the right troubleshooting steps, most common issues can be addressed without the need for extensive professional help. However, recognizing when to involve expert technicians is crucial to ensure your generator’s longevity and reliability.

Investing time in learning about your generator’s specific needs and potential issues, as emphasized through routine checks and the maintenance of crucial components, can significantly prevent unexpected failures. The tips and steps provided in this guide are designed to equip you with the knowledge to maintain your generator’s optimal performance and to handle issues as they arise confidently.

Ultimately, the goal is to ensure that your cummins onan generator repair needs are minimized, allowing you to rely on your generator for continuous and efficient power whenever it is needed. Remember, a well-maintained generator is not just a reliable asset; it’s also a safe one.

FAQs: Common Questions About Cummins Onan Generator Repair

Here are some frequently asked questions about cummins onan generator repair that can help you better understand how to maintain and troubleshoot your generator:

Q1: How often should I perform routine maintenance on my Cummins Onan generator?

- A1: Routine maintenance should be performed according to the schedule provided in your generator’s owner’s manual. Typically, this includes regular checks every 100 hours of operation or annually, whichever comes first. Key activities include changing the oil, checking the spark plugs, and replacing air and fuel filters.

Q2: What are the first things I should check if my generator won’t start?

- A2: First, ensure that there is enough fuel in the tank and that the battery is adequately charged. Check for clogged fuel filters and ensure the spark plugs are in good condition. Also, inspect the starter and other electrical connections for any signs of damage or wear.

Q3: Can I perform repairs on my Cummins Onan generator myself?

- A3: Many basic maintenance tasks can be performed by the generator owner, such as replacing filters, changing oil, and basic troubleshooting as outlined in the owner’s manual. However, more complex issues, especially those involving the electrical system or engine components, should be handled by a professional to avoid causing further damage or voiding warranties.

Q4: What should I do if my generator is producing power inconsistently?

- A4: Inconsistent power can be caused by several issues, including problems with the fuel line, air intake, or a malfunctioning alternator. Check for any blockages or leaks in the fuel and air intake systems. If the problem persists, it may require professional diagnosis and repair.

Q5: How do I find a certified repair service for my Cummins Onan generator?

- A5: You can find certified repair services by contacting the manufacturer directly or visiting their website. They can provide a list of authorized service centers in your area. Always ensure that the service provider is certified to handle Cummins Onan generators to maintain your warranty and ensure high-quality service.

By keeping these FAQs in mind and referring back to them as needed, you can ensure that you are well-prepared to handle common issues and maintain your Cummins Onan generator effectively.

References

Cummins Inc. provides comprehensive technical support and maintenance services for all makes of Cummins generators, ensuring reliable solutions and efficient service to minimize downtime. Their technical support page offers valuable resources for generator maintenance and repair.

RVside.com offers practical tips for troubleshooting Cummins Onan RV generators, emphasizing the importance of understanding the generator’s safety features, maintenance needs, and error codes for effective troubleshooting.

GeneratorStop.com discusses common issues with Onan generators and provides DIY repair tips. It also points to resources for finding manuals and parts diagrams. This can be a helpful resource for more detailed repair steps and finding the right parts for your generator.