Cummins generator services are of special importance since the generator manufacturers are in the power generation business. They make energy solutions and power generating units that are crucial for providing energy in such diverse industries as healthcare, data centres and manufacturing. Since these industries of great import require uninterrupted, reliable power supply, it is pertinent that these Cummins generators are as durable and efficient as they can be. It is also true, however, that to maximise the potential of your Cummins generator, you need not only to purchase it and install it but also to regularly, meticulously service and maintain it.

Maintenance is not a checkup where a doctor lounging on a massage chair listens to your heartbeat for a fleeting moment while you are seated comfortably on a couch. It is as a financial investment for the lifetime and dependability of your power generation equipment. The widely recognised power systems expert, James Hamilton, once said: “A generator is as reliable as its maintenance programme. Failure to service on schedule is an invitation to failure.” This goes to show that Cummins generators service is highly significant as they keep the powerhouses at the top of their game, helping them to avoid expensive breakdown and repairs.

You know, paraphrased version: ‘Regular servicing of a Cummins generator makes it more efficient. That’s because that servicing finds and fixes small problems before they have a chance to turn into big problems and seriously impact the unit’s ability to maintain proper essence.

Finally, understanding the crucial importance of Cummins generators service will start you down the path to enjoying the reliability and efficiency you deserve from your generator purchase. That means committing to a maintenance plan that will protect your purchase and deliver continuous, efficient, reliable electric power for years to come.

The Fundamentals of Cummins Generator Maintenance

Maintaining amedical generator service is key to ensure that your generator operates at maximum efficiency, optimum reliability and a longer life. At the base of a good maintenance program is adherence to service schedule prescribed by the generator’s manufacturer. This is not just a suggestion by your manufacturer! It is a carefully designed timetable to ensure that all the components of your generator are operating at optimum conditions, as stated by Alex Martinez, one of the pioneers of generator technology: ‘Sticking to the service schedule is like giving your generator a new lease on life at a regular interval.

The basic maintenance service for tyler generators includes a wide array of checkups and services, to preserve the performance of the generator:

- Fuelling System: We check this weekly (minus the radiator cap and dip-stick) to make sure there is no clogged fuel stream depriving parts of necessary fuel. We also clean it so that the engine isn’t working as hard as things get dirty. Contamination can be quite damaging and can seriously affect efficiency You might be wondering, isn’t this supposed to be about positive thinking? Won’t all this analysis and hard work get me down in the dumps? The answer is no, it won’t. Here’s why.

- Air Intake System: Check that the air intake is not blocked so that the air-to-fuel ratio cannot be detected, and that the engine does not become overheated, which could lead to damage.

- Cooling System: Ensure that the cooling system’s coolant level is correct, and look for any indications of a coolant leak. The cooling system is a key element in keeping the generator running at a normal (and safe) operating temperature, so any indication of a problem should be checked and addressed.

- Oil System: Regular oil changing, oil and grease supply your generator’s moving parts continuously. The oil system could reduce friction between generator parts, thus protect your Cummins generator from wear and heat damage that will shorten your generator’s service life.

It’s not the schedule, but the understanding of the importance of each part in the whole system of your generator engine and how each one is interconnected in keeping the generator going smoothly and ceaselessly. Cummins generators service means routine check-up of every part of your continuity generator, minimising the occurrence of downtime and hefty repairs.

For one, maintenance is a holistic approach, rather than a set of checks and cleanings. As Martinez reminds his readers: ‘Good maintenance today is the guarantee to tomorrow reliability.’ In other words, internalising these basics is absolutely necessary to extract the full potential out of your cummins generator parts.

Advanced Maintenance Techniques for Enhanced Performance

Looking even deeper into the Cummins generator maintanence, sometimes there are a lot of hi-tech method executions and diagnoses for solving these issues. These methods are not just for maintenace, but used to predict and avoid these situations. And hi-tech tools are always involved.

Diagnostic Tools and Techniques: Common diagnostic tools are used today to gain insight into the operational health of the Cummins generator. Software and hardware diagnostics allow for irregular patterns, wear and failures to be observed before they become large problems. Vibration analysis and thermal imaging are just a few of the methods that can be used to diagnose the condition of a generator, and allow for pinpoint challenges to arise before an extensive issue.

In support of this cutting-edge diagnostics, the leading generator maintenance expert Dr Emily Robertson notes: ‘Modern diagnostic tools take care of maintenance and turn it into an exact science, this helps not only to extend the life of the generator but also to improve its performance and fault-resilience.’

By anticipating the most common problems faced by Cummins generators, uptime and opportunity can be maximised: – Faulty batteries often lead to starting problems. Constant testing and batteries replacement (depending on diagnosis info) can both prevent this issue – Clean and tight connections can avoid electric failures.

Performance-oriented maintenance planning: Setting up with fine-grained service practices, and while emergency maintenance might be needed from time to time, advanced maintenance will be about adjusting settings to match demand (hence reducing wear and increasing efficiency), as well as setting the generator up in a way which optimises its performance.

‘Good service practices, based on detailed diagnostics, keep the generator running and set it up to run in just the right way for whatever demands its environmental context sets it,’ writes Robertson. ‘A good service practice is a carefully contestable and debatable prospect that reduces improbabilities before they become problems.

Advance diagnostics based on years of actual maintenance support can help Cummins users to think beyond repair and maintenance: advanced maintenance helps improve the performance of Cummins generator and assists in achievein higher value from every Cummins generator. These advanced practices ensure that each diesel generator from Cummins is always operating at its best while delivering as much power as possible when needed the most.

Cummins Generators Service: European Best Practices

Cummins generators in Europe have the benefit of being upheld to mandatory safety and environmental standards, which become a significant parameter of maintenance policies. These standards not only extend the potential operational life of the equipment, but also ensure that Cummins generators stay efficient, reliable and sustainable over time. European best practices in generator maintenance are built upon an extensive knowledge of safety and environmental standards, which are adapted to the specific commercial needs of the major European markets.

Following European Standards: Cummins generator operators make use of a comprehensive set of requirements established by the European Union which govern aspects such as service intervals, maintenance guidelines, noise-dampeners, emissions levels and even the kind of lubricants and fuels used. Cummins is ISO 14001 certified for the environmental management of their entire production chain, ensuring that their operations follow directives. The strict standards adhered to offer businesses a great resource for engaging with customers and widening their networks.

As Hans Müller, vice president of one leading European specialist for legislative compliance in power systems, put it: ‘Because there are high standards for European [generator maintenance] compliance, it is broader than just legal compliance. It represents an aspiration toward operational excellence and sustainability. It’s an attitude: we do things right. We keep our facilities safe. We have a commitment to quality.’

Other benefits of sticking to the European guidelines as outlined above are that it can also both save fuel and reduce emissions and also make your generator last longer. Additionally, many of these practices generally can help in reducing running costs as well because keeping your generator regularly maintained can help prevent costly breakdowns and help it run more efficiently.

Effective Maintenance Regimes Outside North America, maintenance regimes for Cummins generators that result in reliable performance stress early awareness and prevention, a maximum program of predictive maintenance before devolution into more costly uncorrective maintenance as well as the implementation of appropriate technical and training systems for maintenance personnel to avoid unserviceability caused by operating environments. Finally, an effective maintenance regime should have a new philosophy on generators where all stakeholders understand the whole health picture, not just mechanical, but operating and environmental too.

Müller adds: ‘The message to our generator maintainers is that the best diagnostics, the most skilled workers and the best practices in maintenance are the basis on which you can rely for high availability.’ ‘For us in Europe, this is not only a maintenance strategy, but a philosophy of power generation as a whole.’

Find Best European Practices and see the Cummins generators service in a new way. Following European best practices, the Cummins generators service will not only provide such output to be considered of high-reliability and electrically efficient, but to enable them to be implemented to be in line with ecological and environmentally sound solutions of power generation. With efficient managerial solutions, which are concentrated in a drive to resource-sparing standards and a ‘maintenance before failure’ doctrine, A new Approach For The Best Generator Maintenance as a universal standard.

Preventive Maintenance: The Key to Longevity for Your Cummins Generator

Preventive maintenance is the key to the life and reliability of the Cummins generator, which is the active operating maintenance of the generator to prevent equipment failure before it occurs. A series of check-ups, maintenance and adjustment should be carried out on a regular basis. Make a complete plan of preventive maintenance in order to keep the generator under normal operation, and reduce the risk of sudden failure, thus ensure the normal operation of the generator.

Importance of being proactive: The key aspect of preventive maintenance stands in being proactive, meaning performing a job before something potentially threatening could occur, in contrast to a reactive approach aimed at fixing something after it goes wrong. ‘An ounce of prevention is worth a pound of cure’ – Laura Chen, IEEE senior member and energy systems engineer laid emphasis on the importance of performing preventive maintenance on the solar generators to preserve the good health of them and the company. Performing preventive maintenance also means that Cummins generators will live longer and remain in their optimal efficiency parameters, which consequently reduces the probability of emergency repairs.

scheduling and periodic follow-through entails devising a preventive maintenance schedule unique to Cummins generators by paying a special factor to the model, use and environmental conditions of the generator in question, and it should encompass reglar inspection of critical parts such as the fuel system, air filter, cooling system, electrical connections, change of oil and filter at the prescribed point in time.

‘You have to tailor the schedule to the specific context, if you want to keep up the generator’s health and fully utilise its capabilities,’ Chen says. ‘That means tweaking the regime and adjusting it on the fly, based on operational feedback and information from diagnostic data’.

Maintenance Checklist for Chemical Ancillaries: A checklist should include points that require maintenance like:

Checking air intake tracts and fuel lines for any blockage and cleaning them to ensure an unrestricted flow of air and fuel.

Checking and topping up fluids – whether it’s the coolant or lubricants – so that the device can run cool and smooth.

Testing of battery charge and connections to prevent startup failures.

Inspecting belts and hoses for any signs of wear or deterioration, and changing them accordingly so as not to break down.

Checking that the control panel model number, serial number and ratings match the information on the nameplate.Activating the data display to verify the generator control panel functions and settings are set correctly, so that the generator runs at rated voltage and frequency under load.

Effective preventative maintenance on cummins generators service is a lifelong commitment to excellence. ‘Regularly changing parts and performing preventive maintenance is a statement about our commitment to uptime, efficiency, and the reliability of the generator,’ Chen explains. By providing the best possible care for a Cummins generator, operators can significantly increase its reliability and enhance its performance over the years.

Navigating Challenges in Cummins Generators Service

Ensuring cummins generators service can remain operational is not a simple task. Factors such as diagnosing complicated errors and scheduling maintenance cannot be undermined. A successful strategy will entail overcoming these problems and applying best practices to prevent failure and keep generators service at full capacity.

Maintenance challenges Common challenges include early fault detection and repair. For example, things such as fuel contamination can cause inefficiencies leading to increased wear and downtime. Electrical system failure, like the generator alarm being triggered, can also cause unexpected downtime. This might be caused by vibration from the engine shifting out of its original position. Environmental conditions also affect wear and tear of the generator components, including extreme temperatures, humidity and dust.

‘So, there are a lot of technical challenges to understanding how generators work,’ says Dr. Sara Nguyen, an expert in modern generator technology, ‘to the extent that maintenance of these machines is no longer a trivial problem – it becomes an interesting technical problem.’

Strategic Solutions and Best Practices: The most effective course of action with regard to these challenges includes the use of diagnostic tools tailored for individual units, regular training of maintenance personnel and a maintenance plan that agrees on the structure of maintenance and on the solutions that have proven effective in previous endeavours. The condition-based monitoring is a great tool for early detecting problems and never-ending learning ensures that the maintenance teams are knowledgeable with the state-of-the-art service approaches and technologies being used.

‘This is why it’s really important to take advantage of the new diagnostics that are available, and make sure that your maintenance engineers are trained,’ adds Nguyen. ‘It is very important to stay on top of things. It’s a proactive activity rather than a reactive one.

Professional Service vs In-house Maintenance: One of the main concerns is if you want to use professional Cummins service attendant to perform the service or you want in-house staff to handle it. In-house staff may handle routine maintenance and small repairs but complicated issues might require service from authorised Cummins service staff or equipment to do the job.

‘It’s important to know when to call in an expert,’ adds Dr Nguyen. ‘It’s just as much about having confidence in the service and knowing that a maintenance job will be done professionally, with genuine parts and to the manufacturer’s standards, as it is about a highly skilled difficulty of the repair.’

In short, addressing the maintenance dilemma related to Cummins generators service is no easy task. It necessitates a balanced approach that swings between sufficiently broad expertise to ensure seamless operation, strategic preparedness to identify the best maintenance strategy, and flexibility to modify the maintenance strategy based on upcoming workloads. By exercising expert practices and leveraging professional service to make decisions regarding the Cummins generators, operators can easily navigate the maintenance regime and make the most out of any given situation.

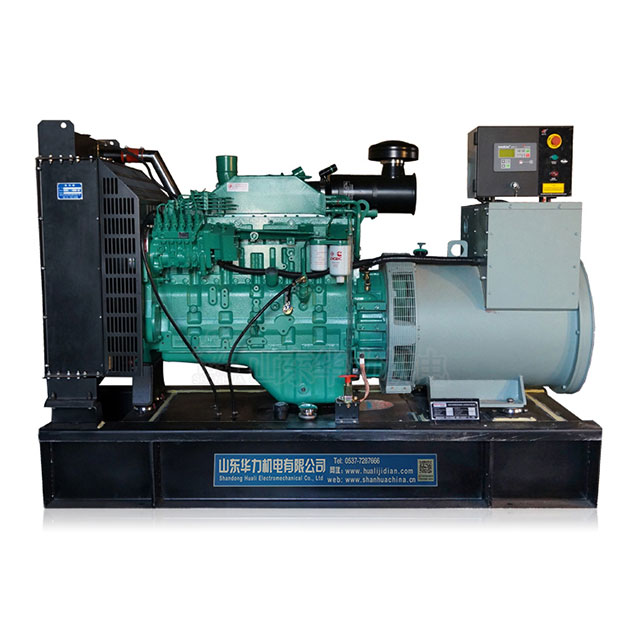

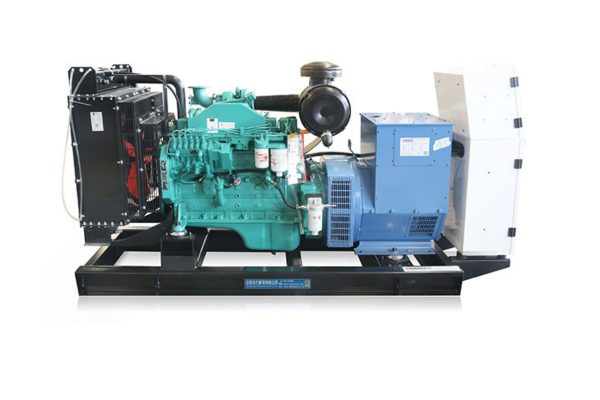

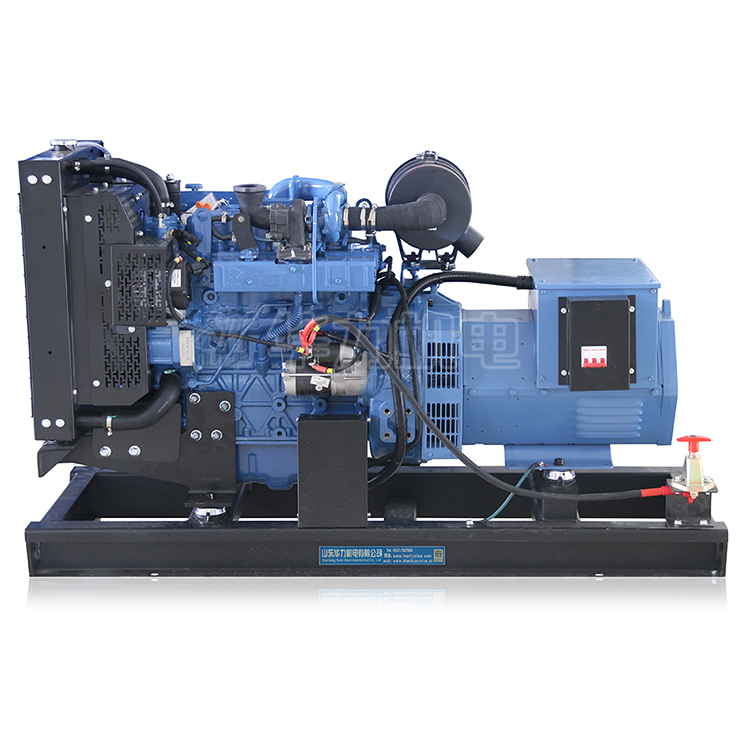

cummins generators serviceImage Source:https://pleavinpower.co.uk/news/what-is-included-in-a-generator-repair-service/

Conclusion: Ensuring the Reliability of Your Cummins Generator Through Expert Maintenance

For any operation that relies on power supply day in and out, keeping the generators by Cummins in good condition is crucial. Using the directions as given in this article by ranging from the facts about the need of Cummins generators service on a regular basis to the utilisation of technology to the main attribute of the those service providers who are true Cummins generators dealer, generator operators can now confidently look out for ways to make their generators work at maximum capacity.

From my vantage point, the path to reliably servicing your Cummins generator must include an emphasis on preventative and predictive maintenance, an appreciation of the complexities of modern maintenance practises, and a willingness to engage service providers before something goes wrong. The secret to getting the most from your Cummins generator, according to Micheal Anderson and Stephen Grant, is a technologically advanced approach to maintenance informed by best practise, a deep understanding of how your generator is meant to operate, and an appreciation of how modern maintenance practices have evolved over time.

The wisdom and long-term benefits of systematic maintenance practices can not be stressed enough. Not only do they prolong the operating life of your generator, they also help the generator stay efficient, which in turn lowers operating costs and reduces the impact on our environment. Routine maintenance ensures readiness and sustainability. It will guarantee that your Cummins generator is always ready to deliver when needed.

And the goal of keeping your Cummins generator in top shape — for unlocking its full performance potential — can almost be achieved only by the consistent maintenance procedures outlined above. With this guide, operators who really place these maintenance priorities first will be better equipped to let their Cummins generators shine even at the extremes of temperature. If they do, they’ll have every reason to trust in the reliability of this power source, on which their teams and their companies depend.

References

Cummins Care Customer Support: Cummins offers comprehensive support for their products, including generators. They provide a search knowledge base, contact information for global support, and the ability to find a dealer or service provider near you.

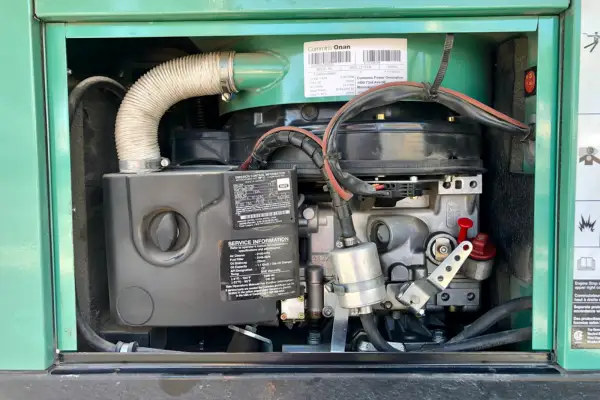

Cummins RV Generator Service and Parts: This section details the service and parts available for Cummins RV generators. It emphasizes the importance of using genuine parts for optimal performance and reliability, and also provides resources for maintenance routines, such as checking air filters, spark plugs, and oil filters.

Shop Cummins for Onan Generator Parts: An official source for purchasing genuine Onan generator parts, ensuring compatibility and performance.

Genuine Cummins Parts: For those looking for genuine parts for their Cummins engine, fleet, or generator, Cummins provides an official online catalog where you can search by engine serial number, part number, or description to find the right parts.

Online Cummins Parts and Service Catalogue: Cummins QuickServe Online is a resource for all your Cummins engine parts and service reference information needs. It offers instant access to parts and service information for over 12 million Cummins engine serial numbers, including manuals, service bulletins, wiring diagrams, and much more. It is updated continuously with the latest information.