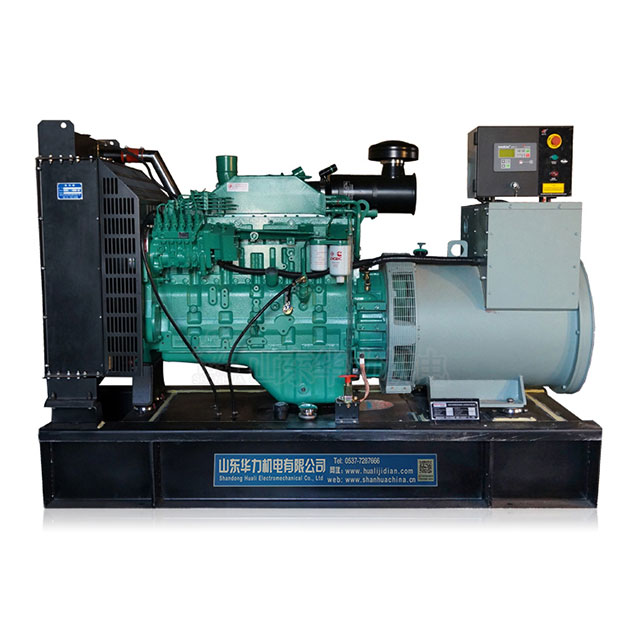

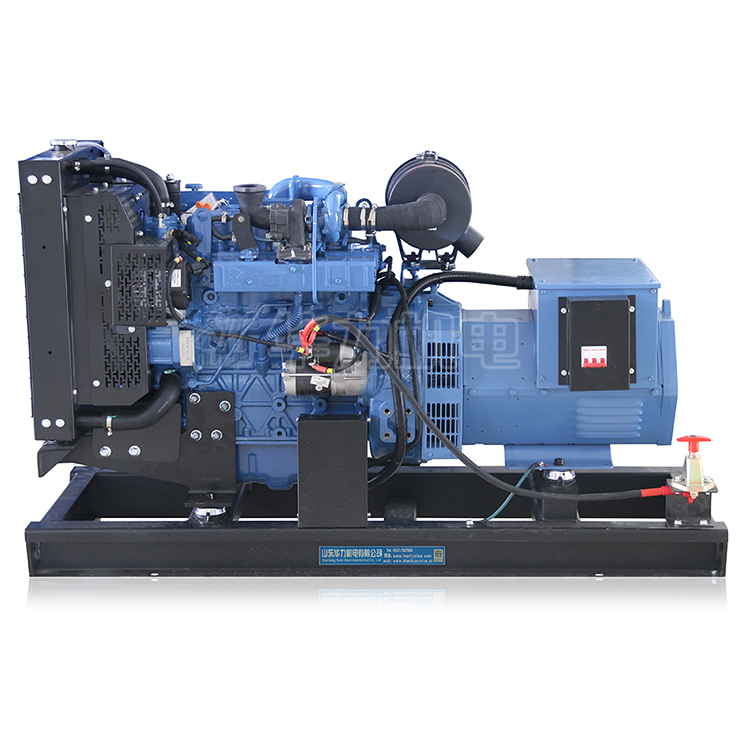

MTU generator engines are the backbone of the energy infrastructure in Europe, ensuring the functioning of hospitals, factories and other critical operations, from industrial sites in the mountains to pharmaceutical sites on islands.

Mounting power demands and the need for robust reliable power solutions are driving Europe’s diverse energy needs. At MTU, our generator engines repair serve as reliable power plants where grid electricity is unavailable, unreliable or simply too expensive. They are capable of delivering power even in the harshest conditions and these are places where, in particularly in critical applications such as hospitals, in data centres, in ambulance or fire brigades, with emergency services or in production, for example, power failure and outages simply are not an option.

MTU generators are used in many different applications in Europe, from construction sites and mines to agriculture and leisure facilities, where they supply primary or standby power. MTU generator engines repair fit for use in very a cold and dry climate – Northern Europe in winter – and for a warm and humid climate in the Mediterranean region.

Fundamentals of MTU Generator Engines

It is very important for the mechanics for MTU generator engines repair to learn the basics If precision engineering were a craft, the MTU generator engine would certainly be a masterpiece since it continues to provide reliable power solutions for different types of applications. In this discussion, we will try to enlighten the basic anatomy of these engines, as well as on the crux of the technology that propels them.

Basic Anatomy of MTU Generator Engines: Key Components and Their Functions

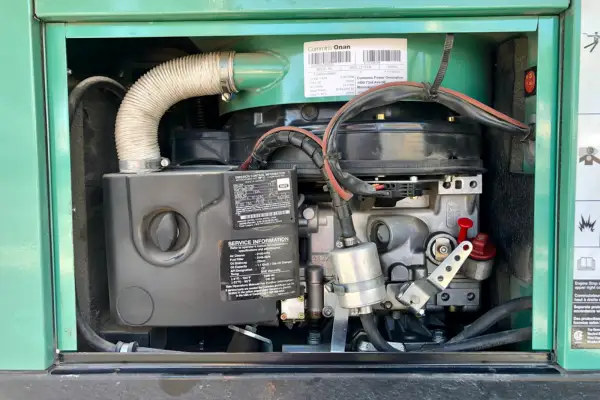

All MTU generator engines consists of at least a set of components that are the following:

- Engine Block: The foundation that houses the cylinders and other components of the engine.

- Crankshaft: Converts the linear motion of pistons into rotational motion to generate power.

- Camshaft: Controls the opening and closing of valves for air intake and exhaust.

- Fuel injection system: Delivers the correct amount of fuel with perfect timing into the combustion chamber.

- Cooling System: Maintains optimal operating temperatures through a coolant that absorbs engine heat.

Understanding the Technology Behind MTU Generator Engines

MTU generator engines repair are renowned for their advanced technology, which includes:

Precise valve timing, with optimised rise time and duty cycle for full maximum crankcase efficiency: a fully sensorised cylinder will continuously send a input feedback to the ECU that will organise boost and switching profiles for the pump, improving efficiency and maintaining low emissions. Common Rail Fuel Injection: The fuel injection, or rather the combustion parameters that define its injection, will be managed hydraulically with nearly 100 per cent precision, avoiding pressure loss in the distribution line due to the relative intensity of its volume (15,000 bar, the Automotive industry’s upper limit).

- Turbocharging: Increases engine power. It involves creating extra airflow into the combustion chamber.

- Exhaust Gas Aftertreatment: Provides technologies such as Selective Catalytic Reduction (SCR) and Diesel Particulate Filters (DPF), comprising different physical components designed for cleaning engine exhaust to enhance efficiency in reducing emissions.

- Advanced Control Systems: Processor-controlled onboard computer that continuously monitors and alters engine parameters in real time, optimising engine operation and improving fuel economy.

Thanks to that knowledge, a repair technician can gain a real understanding of what inside the generator of the MTU engine engine accounts for it to work like it does. That allows them to dive into complex cause-and-effect relations between components and parts and work out the root of the problem through diagnosis and repair. Such foundational knowledge of the MTU engines is therefore crucial to maintaining high performance standards and faultless operation at any time.

Image Source:https://www.aggbusiness.com/ab7/news/rolls-royce-powers-ahead-first-half-2021

Common Issues in MTU Generator Engines

An MTU generator engine is made to be robust and reliable. However, all equipment and machinery, especially complex ones, will wear out. Where failure is possible that could compromise performance, the problem must be identified and actioned before an incident occurs.

Identifying Signs of Wear and Potential Failures in Engine Components

Common signs of wear in MTU generator engines include:

- Lower Power Output: Reduced power output can be caused by something as simple as a fault with the fuel system or by a plugged air intake.

- Strange Noises: Knocking, rattling or any unconventional engine sounds might signify a mechanical problem such as bearing failure or piston assembly issues.

- Oil Leaks:‣ Oil spots under the engine can indicate a leak. ‣ Weird oil consumption can also indicate an issue with a seal or gasket.

- Soot: Exhaust smoke can be a sign of problems; thick black smoke may indicate incomplete combustion; blue smoke can mean burning oil.

Troubleshooting Common Electrical and Mechanical Issues

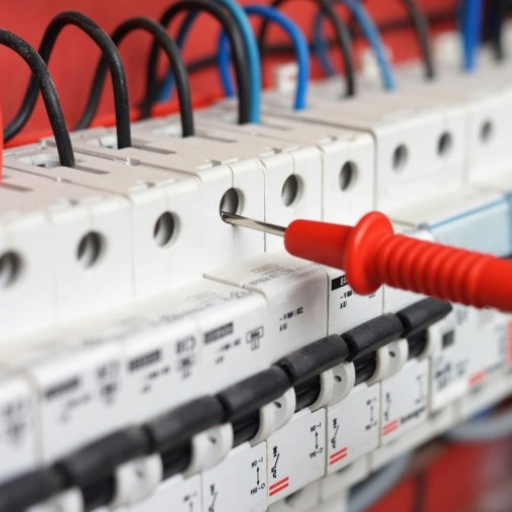

Troubleshooting MTU generator engines, in a way that fixes both kinds of problems – electric and mechanical – has to follow some systematic method:

- Electrical Problems: Check the battery condition and cable connections first, if it is fully charged.Check the voltage and resistance using multimeter.

- Mechanical Problems: Listen for any unusual roughness or length in the sound of the engine, which might suggest a malfunction or damage to some internal part of the engine. Look at movable parts that could be wearing down, or, worse, are broken. Are the engine’s fuel and air filters clean, and is there anything blocking either the air intake or the exhaust system?

MTU generator engines repair is always done by combining technical understanding, keen observation and practical experiences. The early detection and proper diagnosis of problems can prevent minor issues from developing into major failures and make sure these engines keep running at their best. The Regular maintenance and keeping up with service schedules are the best ways to defend against problems and keep the engines ready for action when they are needed most.

Preparatory Steps for Engine Repair

Before diving into the repair of MTU generator engines, certain preparatory steps must be undertaken to ensure the safety of technicians and the effective diagnosis of issues. These steps lay the groundwork for a smooth repair process.

Safety Protocols and Tools Required for MTU Generator Engines Repair

Safety must always be the top priority. Adhering to the following protocols is essential:

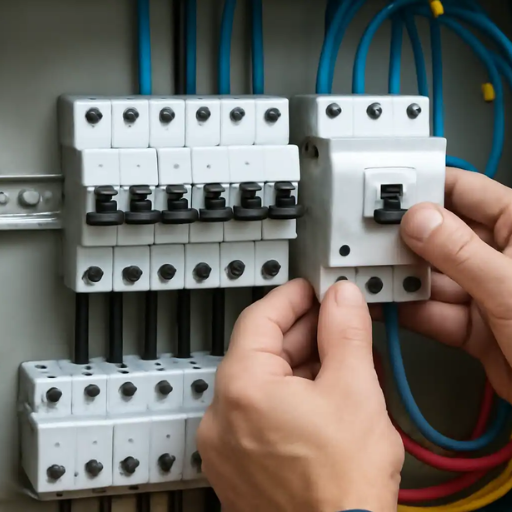

- Disconnect the Power: Ensure the generator is off and disconnected from any power source to prevent accidental starts.

- Wear Proper Protective Equipment: Gloves, safety glasses, and appropriate footwear should be worn at all times.

- Ventilate the Area: If working indoors, ensure proper ventilation to avoid the accumulation of exhaust fumes.

Having the right tools at hand is crucial for efficient repair work:

- A set of wrenches, screwdrivers, and pliers for dismantling and reassembling parts.

- A digital multimeter for electrical diagnostics.

- Specialized tools recommended by MTU for specific engine models, ensuring compatibility and precision.

Initial Diagnostics: Best Practices for Assessing Engine Condition

Conducting a thorough initial diagnosis can pinpoint the exact issues needing attention:

- Visual Inspection: Look for signs of wear, oil leaks, or damaged components.

- Check Engine Codes: Modern MTU engines are equipped with diagnostic systems that can provide error codes, offering clues to the underlying issues.

- Listen to the Engine: Upon starting, listen for any unusual noises that could indicate problems such as bearing failure or misalignments.

By following these preparatory steps, technicians can ensure that they approach MTU generator engines repair with the necessary safety measures in place, equipped with the right tools and a clear understanding of the engine’s condition. This preparation is critical in facilitating efficient and effective repairs, ultimately ensuring the generator’s return to optimal performance.

Step-by-Step Repair Processes

Tackling the repair of MTU generator engines repair demands a methodical approach to address each system’s complexities. Here’s a detailed walkthrough for electrical system repairs, mechanical repairs, fuel system maintenance, and cooling system upkeep.

Electrical faults can significantly impact the performance of MTU generator engines. Begin by:

- Inspecting Wiring and Connections: Check for any loose, frayed, or damaged wires. Ensure all connections are secure and corrosion-free.

- Testing Electrical Components: Use a multimeter to test components such as the alternator and starter motor for proper function. Any components not meeting specifications should be repaired or replaced.

- Battery Maintenance: Verify the battery’s charge level and look for signs of corrosion on terminals. A well-maintained battery is crucial for reliable starts.

Mechanical issues require a keen understanding of the engine’s inner workings. Focus on:

- Replacing Worn Parts: Components like belts, hoses, and filters that show signs of wear should be replaced to prevent failures.

- Engine Overhaul: For more severe mechanical issues, such as damaged pistons or bearings, a complete engine overhaul may be necessary. This process involves disassembling the engine, repairing or replacing damaged components, and reassembling.

The fuel system is vital for the engine’s operation. Key maintenance tasks include:

- Cleaning or Replacing Fuel Filters: Dirty fuel filters can restrict fuel flow, leading to performance issues.

- Inspecting Fuel Lines and Connections: Check for leaks or damage that could affect fuel delivery.

- Adjusting Fuel Injection Timing: Proper timing is essential for efficient combustion. Refer to the MTU service manual for specific adjustment procedures.

The cooling system plays a crucial role in engine health by regulating temperature. Maintenance steps involve:

- Checking Coolant Levels: Ensure the coolant is at the recommended level and replace it according to the maintenance schedule.

- Inspecting Radiator and Hoses: Look for leaks or blockages that could impair cooling efficiency.

- Cleaning the Cooling System: Remove any debris from the radiator fins and ensure adequate airflow for effective cooling.

By following these step-by-step repair processes, technicians can address the multifaceted needs of MTU generator engines, ensuring they return to optimal operation. Each system within the engine has unique requirements, and addressing them with precision is key to successful maintenance and repair. Regular attention to these areas can prevent significant issues and extend the engine’s service life.

Advanced Diagnostic Tools and Techniques

Leveraging advanced diagnostic tools and techniques is essential for the precise maintenance and repair of MTU generator engines. These tools not only streamline the diagnostic process but also enhance the accuracy of troubleshooting, ultimately leading to more effective repairs.

Modern MTU generators are equipped with sophisticated software that can provide comprehensive diagnostics, including:

- Engine Management Systems: These systems offer real-time monitoring of engine performance parameters, facilitating early detection of potential issues.

- Diagnostic Software: Specific software tools designed by MTU allow for detailed analysis of engine data, helping to pinpoint the exact cause of problems.

- Performance Optimization Tools: Software solutions are available to optimize engine settings for enhanced efficiency and performance, based on the diagnostic data collected.

Using Original Equipment Manufacturer (OEM) tools ensures that all diagnostics and repairs are done to the manufacturer’s exact specifications:

- OEM Diagnostic Kits: These kits include specialized tools and software provided by MTU, ensuring compatibility with their engines. They enable technicians to perform accurate diagnostics and make precise adjustments.

- Technical Support Access: Often, OEM tools come with the advantage of direct support from MTU, providing access to expert advice and troubleshooting assistance.

Incorporating these advanced diagnostic tools and techniques into the maintenance routine of MTU generator engines ensures that all repairs and adjustments are carried out with precision. This not only safeguards the engine’s performance but also extends its lifespan by ensuring issues are accurately identified and rectified. By staying up-to-date with the latest diagnostic technologies, technicians can maintain the high standards of reliability and efficiency that MTU engines are known for.

Preventive Maintenance Strategies

The longevity and performance of MTU generator engines greatly depend on preventive maintenance. By implementing a comprehensive maintenance strategy, potential failures can be avoided, ensuring the engines operate reliably and efficiently. Here’s how to establish effective preventive maintenance for MTU engines.

Regular inspections are crucial for identifying early signs of wear or damage. Key components to check include:

- Air and Fuel Filters: Replace these filters at intervals recommended by MTU to ensure clean air and fuel supply to the engine.

- Oil Changes: Regular oil changes are vital for engine lubrication and cooling. Use the specific oil type recommended by MTU.

- Cooling System: Check coolant levels and the condition of hoses and the radiator to prevent overheating.

Not all MTU engines will have the same maintenance needs. Customizing maintenance plans involves:

- Understanding Specific Engine Models: Different models may have unique requirements for maintenance and service intervals.

- Monitoring Usage Patterns: Generators used continuously have different wear patterns compared to those used sporadically. Adjust maintenance schedules based on operational hours and load conditions.

Incorporating these preventive maintenance strategies ensures that MTU generator engines remain in peak condition, minimizing downtime and extending their operational lifespan. Regular maintenance not only safeguards the engine against unexpected failures but also optimizes its performance and efficiency, contributing to overall cost savings.

Conclusion and Best Practices

The path we followed in learning the repair of MTU generator engines whole shows not only how difficult it is to troubleshoot their mechanisms, but also the delight to get them working not only at optimal performance, but also at the highest level.

In this detailed manual, the importance of following systematic approach in isolating the cause of the failure and in regular service has once again been highlighted. Speaking about your future professional growth, it is encouraged to take extra courses to stay up to date with newest technologies available at every step of the generator’s repair.

By now, we have learned to diagnose problems and repair an MTU generator engine through the essential steps; from their basic anatomy and problems, to conducting detailed curative actions and preventive maintenance strategies.The use of diagnostic tools and strict safety rules have been stressed to be crucial factors in ensuring successful MTU repairs.

MTU engineer’s field is a fast evolving area, with new technologies and methods coming up every day and new situations must be assessed and new solutions found. This is why the continuous learning and adapting is devoted.That’s why he says professionals in that field should:

- Continuing Education: If you want to maintain your edge, you’ll need to stay abreast of the latest technologies with training courses and certifications.

- Leverage ResourcesUnderstand From: Delve deeply into two targeted areas of expertise, constantly seeking advanced information through technical manuals, online courses and industry forums, to build stronger capabilities and resilience.

- Get connected: Join professional networks to share information, deliver training, solve problems, and build collective knowledge.

Finally, learning to care for MTU generator engines is a lifelong dynamic process and we need elite craftspeople to help us along that journey. If enough of us read this and use some of these techniques, the MTU service experts of the future will be well trained to serve our critical infrastructure, and MTU engines everywhere will be cared for with the utmost care and attention. The path towards mastery in MTU engine repair is a commitment to excellence and innovation, and the ability to stay strong under every rough wave and storm.

References

MTU Solutions: Offers a wide array of services including repair, maintenance, and parts for diesel generator sets. They emphasize on robust design, optimal fuel consumption, and reliability across various applications such as healthcare, data centers, and more.

Mitchell Powersystems: As the official MTU Solutions UK Aftersales Service Support Dealer, they provide overhaul & repair services and genuine MTU parts for a range of industries. Their services include maintenance for emergency and standby generators across various sectors.

W.W. Williams: They serve as an authorized distributor for MTU America Inc., offering diesel engine repair, parts, service, and more. Their locations span across multiple states, providing accessible service options for MTU generator owners.

Bartech Marine: With a focus on quality and OEM support, Bartech Marine is highlighted for its MTU engine expertise. They offer repair, overhaul, servicing, and parts with a strong emphasis on training and OEM support for their engineers.

Central Power: Known for fast diagnosis, rapid repair times, and a robust parts department, Central Power provides generator installation, repair, and service, particularly noted for their service in the Phoenix.