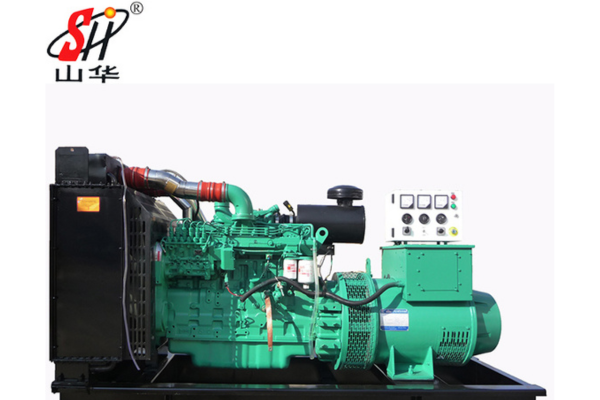

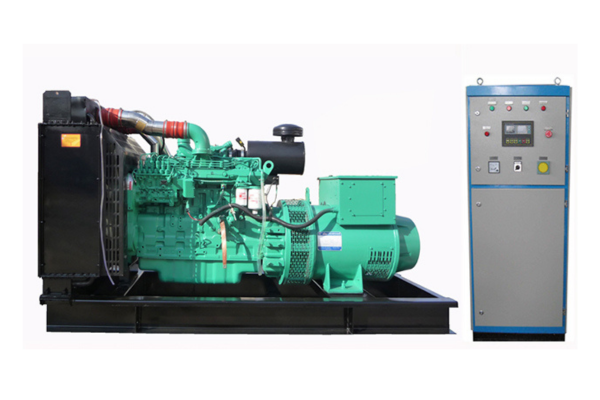

Maintaining a Cummins generator is crucial for ensuring it operates efficiently and reliably over its lifespan. Regular maintenance not only extends the operational life of the generator but also prevents costly repairs and downtime. Cummins generators, known for their durability and performance, come in various models tailored to different applications, ranging from residential use to industrial settings.

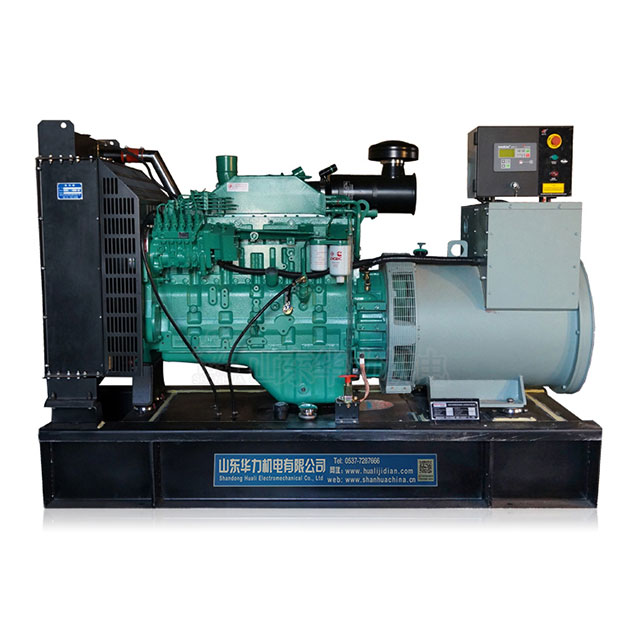

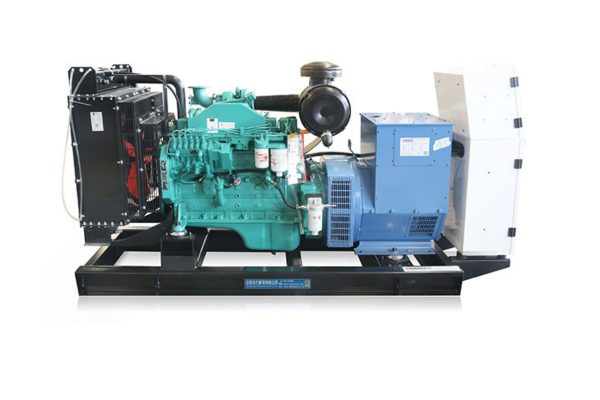

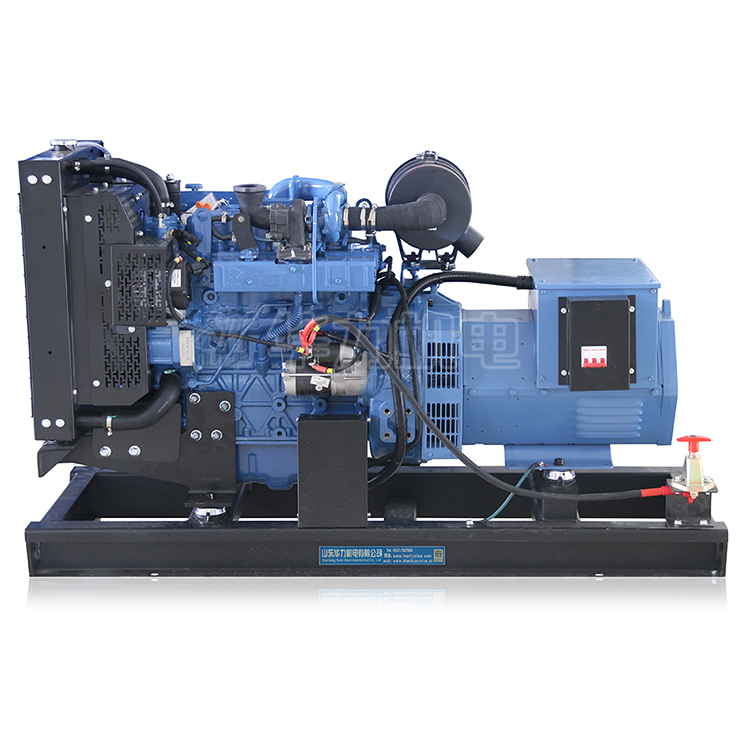

Cummins and Its Generators: Cummins Inc. is a global leader in power solutions, offering a broad array of generators designed for a variety of markets. These include portable units for small-scale applications and large diesel systems designed for industrial use. Each type of generator has specific maintenance needs that, when addressed regularly, can prevent the majority of operational issues.

Understanding the significance of scheduled maintenance is the first step toward mastering Cummins generator repair. By committing to a routine maintenance schedule, you are not only safeguarding your investment but also ensuring that your generator is ready to perform when needed most.

In the following sections, we will delve deeper into the mechanics of Cummins generators, explore diagnostic tools for effective maintenance, and discuss both routine and advanced repair techniques. This foundational knowledge will equip you with the tools needed to ensure your Cummins generator provides reliable power for years to come.

Understanding Cummins Generator Mechanics

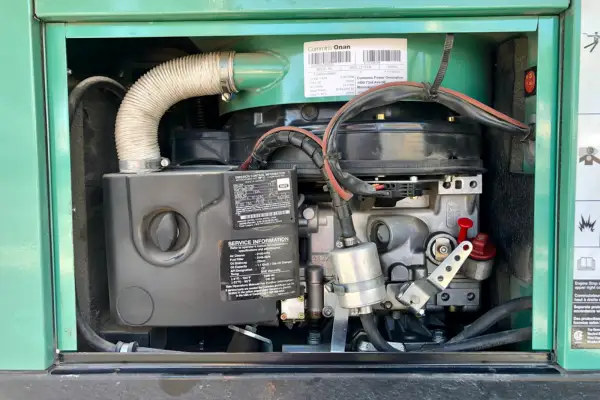

To effectively maintain and repair Cummins generators, a thorough understanding of their mechanical components and common issues is essential. Here’s a detailed exploration of the key parts and typical mechanical problems associated with Cummins generators:

Key Components of Cummins Generators:

- Engine: The heart of any Cummins generator, where fuel is converted into mechanical energy. Components like pistons, crankshafts, and camshafts play critical roles in the engine’s operation.

- Alternator: Converts mechanical energy from the engine into electrical power. It consists of a rotor, stator, and diodes, all of which must be in good condition to ensure efficient power output.

- Cooling System: Keeps the engine at an optimal operating temperature. Includes a radiator, coolant, hoses, and fans.

- Fuel System: Includes tanks, fuel pumps, injectors, and filters. Proper maintenance is crucial for efficient fuel consumption and performance.

- Control System: The user interface that monitors and controls generator operations, including start-up, shut down, and protective measures against operational faults.

Common Mechanical Issues:

- Battery Failure: Often the first point of failure in a generator. Regular testing and charging are vital to prevent start-up issues.

- Coolant Leaks: Can lead to overheating, which is dangerous for engine health. Routine checks for leaks and coolant levels are necessary.

- Fuel System Issues: Dirty fuel or clogged filters can lead to poor engine performance or failure to start. Regular replacement of filters and using clean, high-quality fuel are best practices.

- Worn Out Belts and Hoses: These can lead to failures in the cooling and charging systems, so they should be inspected regularly for signs of wear and replaced as needed.

- Control System Malfunctions: Faults in the control system can lead to incorrect readings and operational failures. Regular firmware updates and checks are recommended.

Impact of Mechanical Issues on Generator Performance: Mechanical issues can lead to reduced efficiency, increased fuel consumption, and, in worst cases, complete system failures. Understanding these components and their common faults helps in preempting major repairs, ensuring that the generator performs reliably, especially during critical times when power is needed the most.

By mastering the mechanics of your Cummins generator, you can effectively diagnose issues before they become serious problems, leading to more efficient repairs and longer-lasting performance. This foundational knowledge is crucial for anyone looking to maintain or repair Cummins generators effectively. Next, we’ll delve into the diagnostic tools and techniques that can help identify these issues more precisely.

Diagnostic Tools and Techniques

Effective maintenance of Cummins generators relies heavily on the ability to accurately diagnose issues before they escalate. Utilizing the right diagnostic tools and techniques is crucial in identifying and resolving problems efficiently. Here’s a detailed guide on the tools used and the steps involved in diagnosing issues with Cummins generators:

Diagnostic Tools Used in Cummins Generator Repair:

- Electronic Service Tools (EST): These are software-based tools like Cummins INSITE or QuickServe Online (QSOL) that allow for deep diagnostics, performance analysis, and monitoring of engine functions.

- Multimeters: Essential for testing electrical components, multimeters can help diagnose issues with the generator’s alternator or battery.

- Load Banks: These devices simulate electrical loads to test whether the generator can handle its intended load effectively.

- Thermal Imaging Cameras: Useful in identifying overheating parts or electrical faults by detecting heat signatures.

- Oil Analysis Kits: These can analyze engine oil for contaminants and wear metals, which can indicate internal engine wear before it becomes a significant problem.

Step-by-Step Guide on Using Diagnostic Tools:

- Connect EST Software: Hook up the EST software to the generator’s data link connector. This tool will read various operational parameters and fault codes which are critical in pinpointing issues.

- Run Full Diagnostic Scan: Using the EST, perform a full diagnostic scan to retrieve any fault codes and monitor live data for anomalies.

- Check Electrical Outputs: Use a multimeter to test voltage outputs from the alternator and battery to ensure they are within specified limits.

- Perform Load Testing: Connect a load bank and run the generator at full load to verify that it can handle the load and to check for performance issues under stress.

- Inspect for Leaks or Overheating: Use thermal imaging to check for hot spots or areas where there is excessive heat, which can indicate potential failures.

- Analyze Engine Oil: Send a sample of the engine oil to a laboratory for analysis or use an on-site oil analysis kit to assess the engine’s internal condition.

Importance of Regular Diagnostic Checks: Regular diagnostic checks allow for early detection of potential issues, which can be resolved before they lead to major failures. This practice not only extends the life of the generator but also ensures it operates efficiently when needed most. Technicians should keep detailed records of all diagnostic results to track the generator’s health over time and predict when parts might need replacing or servicing.

By mastering these diagnostic tools and techniques, you ensure that your Cummins generator is always in optimal working condition, reducing downtime and repair costs. In the next section, we will explore routine maintenance procedures that are essential for keeping your Cummins generator running smoothly.

Routine Maintenance Procedures

Maintaining a Cummins generator through regular, scheduled procedures is key to ensuring its reliability and longevity. Implementing a comprehensive routine maintenance schedule prevents common mechanical failures and keeps the generator ready for uninterrupted operation. Here’s a guide to the essential maintenance tasks for Cummins generators:

List of Essential Routine Maintenance Tasks:

- Oil and Filter Changes: Regular oil changes are crucial for the health of the engine. Replace oil and oil filters at intervals recommended by Cummins, typically every 250-500 hours of operation, depending on the model and usage conditions.

- Coolant Level and Quality Check: Inspect coolant levels and quality before each use. Replace coolant as recommended, usually every 2 years, to prevent corrosion and overheating.

- Fuel System Maintenance: Drain and replace fuel filters and check for water or sediment buildup to ensure clean fuel supply and prevent injector and pump damage.

- Air Filter Replacement: Clean or replace air filters regularly to prevent dirt, dust, and debris from entering the engine and reducing its efficiency.

- Battery Inspection and Care: Check battery charge and clean terminals regularly to ensure reliable starting. Replace batteries as needed, typically every 3-5 years.

- Belt and Hose Inspections: Inspect belts and hoses for signs of wear or cracking. Replace worn parts to avoid unexpected failures related to the cooling and charging systems.

- Control Panel and Connections Check: Regularly inspect the control panel and electrical connections for signs of wear or corrosion. Tighten connections and replace damaged wiring as necessary.

How Regular Maintenance Prevents Mechanical Failures:

- Prevents Buildup of Contaminants: Regularly replacing filters and fluids eliminates contaminants that can wear down engine components and lead to failures.

- Reduces Wear and Tear: Frequent inspections and replacements of wearable parts like belts and hoses reduce the overall wear and tear, extending the life of the generator.

- Ensures Efficient Operation: Keeping all systems clean and well-maintained ensures that the generator operates efficiently, providing reliable power and reducing fuel consumption.

- Avoids Costly Repairs and Downtime: By catching issues early during routine checks, you can prevent small problems from turning into major failures that require expensive repairs and cause significant downtime.

Implementing these routine maintenance procedures as part of your ongoing care for a Cummins generator will significantly enhance its performance and reliability. This proactive approach not only saves money in the long term but also ensures that your generator is always ready when you need it most. In the next section, we will delve into advanced repair techniques for dealing with more complex issues that may arise despite regular maintenance.

Advanced Repair Techniques

When routine maintenance isn’t enough to solve a problem with a Cummins generator, advanced repair techniques become necessary. These methods address more complex issues that can arise, often involving deep system diagnostics, component overhauls, or replacements. Here’s an exploration of advanced repair techniques useful for maintaining long-lasting performance in Cummins generators:

In-depth Discussion of Advanced Repair Techniques:

- Component Overhaul: For components that are worn out or damaged beyond simple repairs, a complete overhaul may be required. This involves disassembling the component, cleaning all parts, replacing worn out parts, and reassembling it. Common components that might need an overhaul include the turbocharger, fuel injectors, and the engine itself.

- Electronic Control Module (ECM) Reprogramming: The ECM controls the electrical systems and interfaces with the mechanical operations of the generator. Sometimes, reprogramming the ECM can improve performance, resolve software issues, or update the system to handle new types of fuel more efficiently.

- Vibration Analysis: Persistent vibrations can lead to premature wear and tear on the generator. Using vibration analysis tools, technicians can pinpoint the source of the vibration and correct it, which might involve balancing rotating parts, aligning components, or replacing faulty bearings.

- Thermal Imaging: Advanced thermal imaging cameras can detect overheated areas before they fail. This technique is particularly useful for identifying and addressing hot spots in the electrical system that could lead to failures if left unattended.

- Root Cause Analysis (RCA): When a generator fails repeatedly or unpredictably, RCA is employed to dig deeper into the systemic issues. This approach helps in identifying the underlying causes of failures, leading to more effective long-term solutions rather than temporary fixes.

Case Studies Showing Successful Complex Repairs:

- Engine Rebuild: A case study might detail the process of a complete engine rebuild for a Cummins generator that suffered a major failure due to prolonged overheating. The study would discuss how each part was assessed, repaired or replaced, and the outcomes of the rebuild in terms of generator performance and reliability.

- Control System Upgrade: Another case might explore the upgrade of the control system in an older Cummins generator, highlighting the challenges of integrating new technology with older hardware, the steps taken to ensure compatibility, and the benefits realized from the upgrade.

What Can Be Learned from These Repairs:

- Cost-Effectiveness: Sometimes, advanced repairs can be more cost-effective in the long term than repeated minor repairs.

- Prevention Strategies: Learning from complex repairs can help in developing better maintenance strategies to prevent similar issues.

- Upgrade Opportunities: These repairs often reveal opportunities for upgrades that can extend the life and functionality of the generator.

Advanced repair techniques require a deeper understanding of the Cummins generator technology and often need specialized tools and skills. These methods are crucial for resolving complex issues that could significantly impact the performance and lifespan of the generator. By applying these advanced techniques, you ensure that your Cummins generator remains a reliable source of power for critical applications. In the next section, we will discuss the replacement of parts and upgrading components to further enhance generator performance.

Replacing Parts and Upgrading Components

To ensure your Cummins generator continues to operate efficiently and to extend its lifespan, it’s crucial to know when to replace parts and how to upgrade components effectively. Here’s a detailed guide on identifying when parts need replacement and recommendations for upgrading components for better performance and longevity:

Guide on How to Identify When Parts Need Replacement:

- Monitor Wear and Tear: Regular inspections can reveal wear and tear on critical components such as belts, hoses, batteries, and filters. Look for signs of physical damage, such as cracks, fraying, or leaks.

- Adhere to Maintenance Schedules: Cummins provides recommended schedules for replacing various parts. Following these guidelines helps maintain optimal performance and prevent unexpected failures.

- Check Performance Indicators: Decreases in efficiency or power output can indicate that certain components need replacement. Utilize diagnostic tools to help pinpoint underperforming parts.

- Listen to the Generator: Unusual noises, such as knocking, grinding, or humming, can signal that specific parts are failing and need immediate attention.

Recommendations for Upgrading Components:

- Upgrade for Efficiency: Consider upgrading components like the fuel injection system or the exhaust system to improve fuel efficiency and reduce emissions.

- Enhance Reliability: Upgrading electrical components, such as the alternator and control panels, can enhance the reliability of your generator. Modern controls can also offer better monitoring and diagnostic capabilities.

- Improve Environmental Compliance: For older generators, upgrading components to comply with current environmental regulations can be necessary. This might include installing newer, cleaner engines or retrofitting exhaust systems with emissions-reducing technologies.

- Consult with Experts: Before undertaking upgrades, consult with certified Cummins technicians or authorized dealers. They can provide advice on which upgrades are beneficial and compatible with your specific generator model.

Benefits of Timely Replacements and Strategic Upgrades:

- Minimized Downtime: Proactively replacing worn parts and upgrading components can minimize downtime, ensuring that your generator is always ready when needed.

- Extended Generator Life: Regular updates and replacements of outdated or worn components can significantly extend the life of your generator.

- Increased Resale Value: Generators that are well-maintained and upgraded with the latest technology often retain higher resale values.

By understanding when to replace parts and how to strategically upgrade components, you can ensure that your Cummins generator remains a reliable power source. This proactive approach not only saves money in the long run by reducing the need for repairs but also ensures that the generator operates at peak efficiency. In the next section, we’ll explore the benefits of working with Cummins certified technicians to achieve these maintenance and upgrade goals.

Working with Cummins Certified Technicians

For optimal maintenance and repair of your Cummins generator, working with Cummins certified technicians provides numerous benefits. These professionals are trained specifically in Cummins systems, ensuring that all servicing, repairs, and upgrades are performed correctly and efficiently. Here’s why you should consider professional service for your generator maintenance:

Benefits of Working with Certified Technicians:

- Expert Knowledge: Cummins certified technicians are experts in all models of Cummins generators. They have access to the latest training, tools, and diagnostic software provided by Cummins, which allows them to quickly and accurately diagnose issues and perform repairs.

- Genuine Parts: When working with certified technicians, you can be assured that all parts used are genuine Cummins parts. These parts are designed to fit perfectly and function optimally with your generator, ensuring longevity and reliability.

- Warranty Compliance: Maintaining your generator with certified technicians helps keep your warranty intact. Many warranties require that service and repairs be performed by certified professionals to remain valid.

- Up-to-Date Service: Certified technicians have access to the latest Cummins service bulletins and updates. This means your generator will always benefit from the latest service procedures and part updates, keeping it in line with current standards.

How to Find Qualified Service Providers:

- Cummins Dealer Locator: Use Shandong Huali Electromechanical Co., Ltd Cummins dealer locator tool on their website to find authorized service centers near you.

- Service Reviews: Check online reviews or seek recommendations from other Cummins generator owners to find reputable technicians.

- Direct Inquiry: Contact Cummins directly to ask for certified service providers in your area. They can direct you to partners who meet their standards for quality and expertise.

What to Expect During Servicing:

- Thorough Inspection: A comprehensive assessment of your generator’s condition.

- Detailed Reporting: Technicians will provide a detailed report of any issues found and the repairs or maintenance tasks performed.

- Service Follow-Up: Many technicians offer follow-up services to ensure that your generator continues to operate correctly after initial repairs or maintenance.

Choosing to work with Cummins certified technicians ensures that your generator receives the highest level of care, using the most appropriate tools, knowledge, and parts available. This professional attention helps maximize the efficiency, reliability, and lifespan of your Cummins generator, providing peace of mind that your power needs will be met reliably in the future. In conclusion, investing in professional service is a wise decision for maintaining the long-term performance and reliability of your Cummins generator.

FAQs: Common Questions About Cummins Generator Repair

Addressing frequently asked questions is an essential part of understanding the nuances of Cummins generator repair. Here are some of the most common queries that users and technicians encounter, with clear and concise answers to help ensure your generator operates at its best:

- What are the first steps I should take if my Cummins generator isn’t starting?

- Check the fuel and battery: Ensure there is enough fuel and that the battery is charged.

- Inspect the air and fuel filters for blockages.

- Review the error codes on the control panel, if available, for specific troubleshooting.

- How often should I have my Cummins generator serviced?

- Cummins typically recommends a comprehensive service check at least once a year or after 250 to 500 hours of operation, depending on the model and usage conditions.

- Can I perform maintenance tasks on my Cummins generator myself?

- Simple maintenance tasks such as changing filters and oil can be done by the owner if they feel competent. However, more complex services should be handled by certified Cummins technicians to ensure quality and maintain warranty conditions.

- What should I do if I need parts replaced on my Cummins generator?

- Always opt for genuine Cummins parts to ensure compatibility and reliability. You can order these parts through authorized Cummins dealers or service centers.

- What common signs indicate that my generator needs repair or troubleshooting?

- Warning signs include unusual noises (knocking, grinding), frequent shutdowns, power fluctuation, and visible smoke or leaks.

- How can I find a certified Cummins technician?

- Visit the official Cummins website to use their dealer locator tool, which provides information on authorized service centers and certified technicians in your area.

References

Cummins QuickServe Online provides detailed parts and service information accessible by entering your generator’s serial number. This platform is essential for obtaining precise service documents and parts details specific to your generator model

Cummins Inc. offers guidance on identifying your generator model and spec through their “How to Identify Your Generator Model” page. This can be particularly useful if you need to order parts or request service and do not have the serial number readily available

For Genuine Cummins Parts, the official Cummins parts catalog allows you to search by part number or engine serial number, ensuring you get the correct and genuine components necessary for maintaining the reliability and performance of your generator