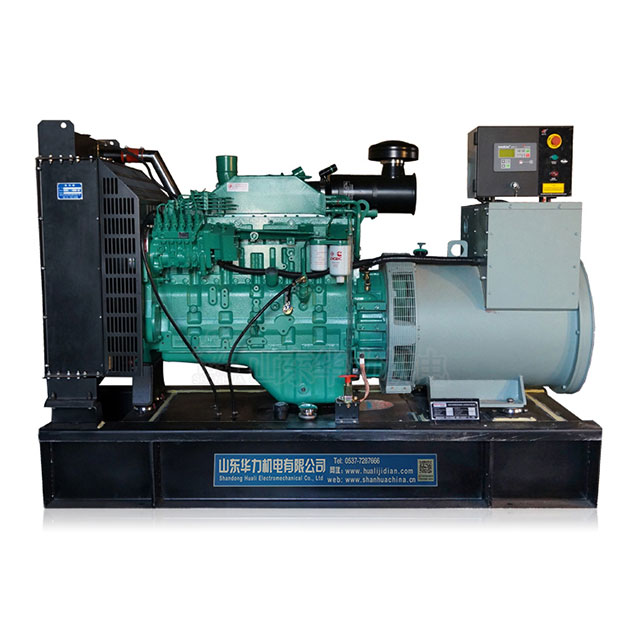

European markets for MTU generator repair and Maintenance,Trusted by 1000 of customers for its strength and reliability, its generator drives a wide variety of applications such as powering small remote villages and maintaining critical infrastructure during power outages. the MTU generator repair is Europe’s trustworthy support for emergency and daily power from big to small.

And maintenance is the key to any generator, maintaining its reliability and prolonging the service life of the unit itself and ensuring that it works at maximum efficiency and provides a high output. As Thomas Edison, the inventor and adept businessman said: ‘The worth of a machine lies in its reliability.’ It appears that this statement holds true for generators, where the price of downtime can often be much higher than the price of maintenance.

Put another way, in order to repair MTU generators successfully, one must learn to think beyond the specifics of a broken machine, towards the electricity supply that hundreds of companies and communities depend on. This would be the first layer, or step, in attaining a domain of human knowledge: a generell overview. The rest can be filled in with more specific, technical details about the technology, the lessons of maintenance, and the need for MTU repair. In doing so, enthusiasts and professionals alike can take part in maintaining the resilience of Europe’s power grid.

Understanding MTU Generator Components

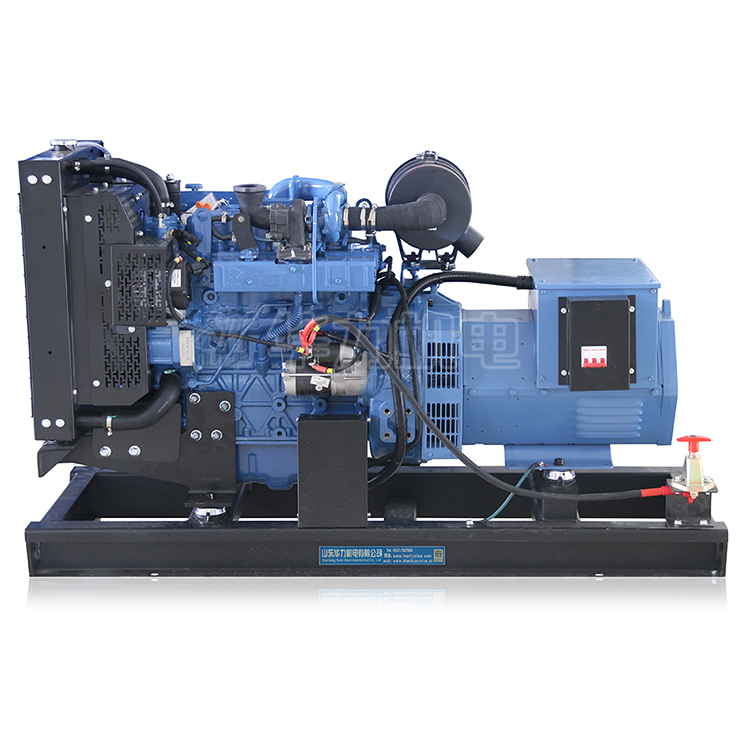

In a nutshell, mtu generator repair involves alternator, control system, cooling system, fuel system, and more.

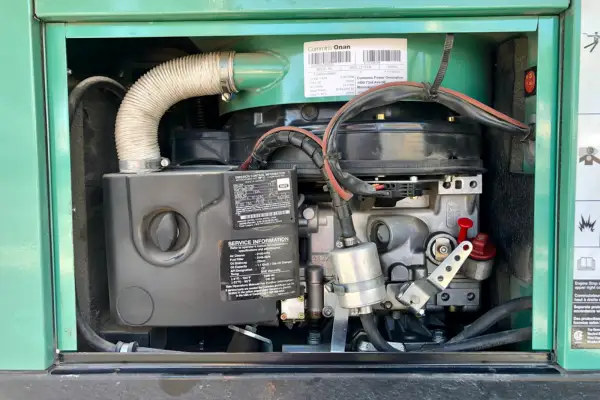

- Engine: At the heart of the generator is an engine that takes a fuel that we buy and runs it into the mechanical juice known as engine out. It was built for quality and performance just like MTU’s engines, down to the last detail.

- Alternator: transform the mechanical energy of the engine into electrical energy. The design is robust enough to provide electricity under changing loading conditions.

- Control System: Principle component of the generator, responsible for monitoring operative parameters and ensuring the conversion process takes place in optimum conditions. It plays a crucial role in diagnostics and preventive maintenance.

- Cooling System: Maintains the engine at its optimal running temperatue. Prevents overheating through careful cooling-liquid circulaiton.

- Fuel System: Brings the fuel into the engine, where it will meet the ignition. Depending on the model, it can be anything from diesel to natural gas. Designed for high efficiency and extended operation.

The fact that each component makes a contribution toward each other in the generation of the MTU generator also reveals that a repair and maintenance strategy should be holistic. For example, when the engine in the MTU generator overheats, it means that the cooling system is not functioning properly. If there’s a problem with the fuel system, the engine may underperform or use excessive fuel to compensate.

These parts have to be understood not just by enthusiasts but by the professionals as well, not just so that mtu diesel generators can be repaired as needed, but so that a problem can be recognised before it grows to the point of a breakdown. Otherwise the mtu generator can’t be relied on for the power it’s there for.

mtu generator repair

Common Issues with MTU Generators

MTU generator repair are durable mechanical systems, but no machine can escape the common problems that come with their consistent use. Knowing and repairing common problems can help the unit stay in good shape and avoid expensive downtime. Here are the common issues in MTU generator repair and tips that you should be aware of to catch the problems when they appear.

- Fuel System Contamination: Contamination in the fuel system is the most prevalent cause of engine issues; it reduces performance and, in severe cases, prevents an engine from starting at all. Fuel filters and tanks should be regularly inspected for signs of dirt, water or microbial growth.

- Cooling System Failures: An overheating generator can suffer serious damage. Check coolant levels, check for leaks, and check that your radiator isn’t clogged with debris.

- Battery Failure: Most generators have batteries that are used to start them. If your battery fails, your generator has failed. You might want to periodically check for battery failure by looking for corrosion around connections, and make sure those connections are tight and free of debris; likewise, you might want to periodically test the battery strength.

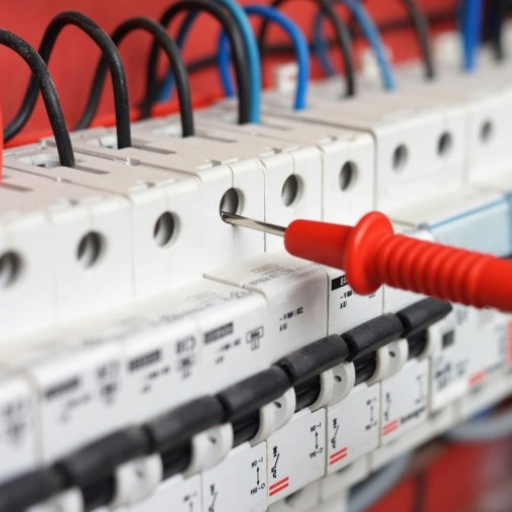

- Control System Malfunctions: The brain of the relationship is the control panel, and problems here affect everything else. Keep these things in mind: firmware updates on an ongoing basis, get those error codes, and make sure that everything is working properly.

- Wear of Mechanical Parts: With continued use, wear of mechanical parts will occur. Visual inspection for wear, listening for unusual noises and monitoring for vibration levels will lead to the replacement or repair of worn parts.

Precasual maintenance of these problems could avoid big accidents, and extends the expiration date of the MTU generator repair. The small little things that are never noticed often explodes as an expensive defect. Include an inspection and maintenance program to frequently identify problems before they develop into critical.

With vigilance and maintenance, MTU generator repair owners can make their units to be an ample source of power. In light of this, when MTU generator repair owners can avoid the situation to take their units to maintain, by that, it can ensure that the generators are working with convenience for better years to come.

Preparing for MTU Generator Repair

Safety is of utmost importance regardless of what kind of mtu generator repair tasks people are about to carry out. So it isn’t enough to know how to handle a specific problem, it’s also necessary to understand exactly how to carry out those repairs as this will enable people to work in an efficient and safe manner. Here is a simple guide to staying safe.

Shut down the generator and disconnect from all power sources Use the specified PPE (personal protective equipment) such as gloves, safety glasses and ear protection Always check for the specific safety measures in the MTU generator repair manual.

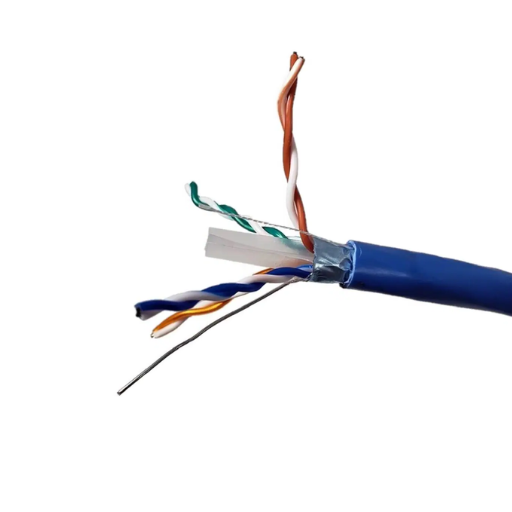

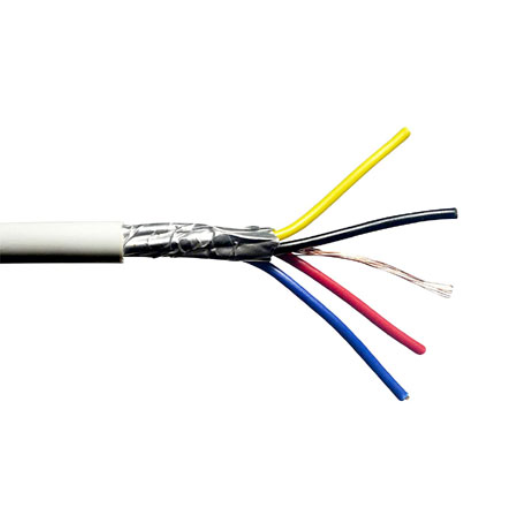

- The Right Tools: You want the right tool for the job. You probably have wrenches, screwdrivers, a multimeter (to check electrical circuit operation), carburettor jets, feeler gages, dial indicator, engine alignment gauge. Make sure they are in good condition and appropriate for the job.

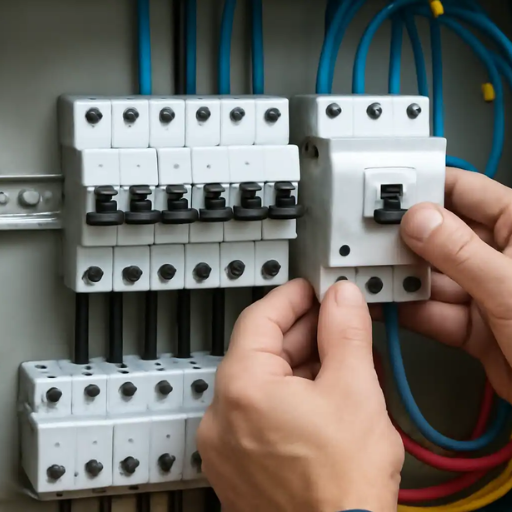

- Initial Diagnostics: Before starting repairs, perform initial diagnostics to identify the location of the fault, including checking the control panel for fault codes, visual inspections and basic tests of the electrical components (conductors, switches, relays and cables) with a multimeter. Modern MTU generator repair systems often incorporate extensive diagnostic systems that may aid in fault diagnosis.

- Service manual:Being able to read the manufacturer’s technical documentation – sometimes called service manual – for your generator is a key resource. It will tell you exactly how to remove and replace any part of this machine. The other thing that technical documentation gives you is critical specifications for components of your machine. With those specs, you can search for parts and find some at reasonably priced elsewhere.

- Clean Working Area: The repair area should be clean and have good overhead illumination.An area strewn with parts can encourage accidents, as well as losing parts. Adequate light is required to help spot wear or damage that might not be readily apparent.

Proper preparation will only make repairing mtu generator easier and will also decrease a chance of damaging the generator further. Taking some time to aairs the folks, gather tools and check the documentation will pay off in the future saving time and money. Preparation is a key part to any repair.

Step-by-Step Repair Guides

In this repair, we show how to address issues with mtu genset repair due to a systematic interactive troubleshooting and solving way on the three major divisions: electrical, mechanical and control section in the power generating system. In the power generation system, a genset mainly consists of electrical, mechanical and control systems. The electrical side supplies power for the genset, the mechanical side turns the shaft to rotate the exciter pole, and the control system mainly controls the working of the two aspects mentioned above.

1 Electrical System Troubleshooting and Repair

Electrical faults are also covered, from simple wiring problems to more complex issues such as alternator or control panel faults. In this section, steps for testing the battery for charge, voltage and continuity, as well as testing the alternator for correct voltage production are outlined. When diagnosing an electrical fault, it is important to refer to the MTU generator’s extensive schematic diagrams in order to pinpoint the problem and select the correct course of action.

2 Mechanical Component Repairs

An MTU generator will not work if its mechanical integrity is compromised. Start with an external generator inspection for any wear or damage. Make sure the fuel and cooling systems do not have any leaks or obstructions that could hinder its functionality. Repairing internal components of an engine like replacing its pistons or bearings would require knowing the intricate assembly of the engine (eg, Notch pattern) and following the manufacturer’s torque specs.

3 Control System Adjustments

The control systems of modern MTU generator repair contain precision adjustables so extensive that to get right you need to calibrate along the path directly to the specification. Often, you can set the calibration using the control panel just to the procedures outlined in the tech manual. Other times, changing or resetting firmware will get around the issue, usually software based. If failures are hardware based, replacing the bad part with an exact match is paramount to maintaining integrity of the system.

If you want to do mtu generator repair the correct way, you have to follow the correct steps, have the right tools for the job, and make sure that you have read the correct procedure for your mtu generator. Regardless if you have an electrical fault, a mechanical part that needs to be replaced, or need to recalibrate some of the system controls, you will restore your mtu generator back to tip-top shape.

When it comes to maintenance for inexperienced DIY’ers, or for complicated repairs beyond basic troubleshooting, professional help ought to be considered in order to ensure that the MTU repairs are both undertaken safely and correctly. The longevity and continued performance of your MTU will depend on it. Most importantly, if, despite your best efforts, regular maintenance fails to head off problems, then following a systematic approach to identifying and repairing the problems will serve you best of all.

Preventive Maintenance Tips

Any generator purchased from MTU will be reliable only if maintain, and the best way to secure a performance of your MTU generator repair is to devote attention even to the minor issues that may not be directly connected with the basic operation. Preventive maintenance may revel even small problems in time, allowing for smaller expenses and avoiding inspections and repairs that will have greater impact on the generator. Here’s, how to keep your generator in the best condition

- Routine Inspection and Cleaning: Inspect your generator for wear, leaks, or damage regularly. Make sure that both the generator and its surroundings are kept clean and are free from dirt, debris, and obstructions that may interfere with ventilation and cooling.

- Check the Fluids: Keep oil, coolant and fuel reservoirs within recommended levels; if they’re way too low – or dirty – engine wear and/or overheating could result. Change and dispose of these fluids as prescribed in your vehicle’s manual.

- Battery Maintenance: Check battery charge and look for corrosion on the battery terminals every month. A maintained battery means your generator will start when you need it to, especially during storms or other emergencies.

- Air Filter Replacement :Check the air filter regularly and clean or replace it as needed. A clean air filter helps the engine run efficiently and at peak condition.

- Fuel System Checks: High-quality, clean fuel is important in diesel generators to avoid contamination (water, debris); drain any water from fuel tank to avoid microbial growth.

- Cooling System Maintenance:

Make sure that the coolant is at the correct level before you run the machine.

Check that the radiator is not leaking, and make sure its cooling fins are free of dirt or obstructions that might stop the air flowing across them. - Give the generator a workout: run it at regular intervals to sharpen your skills and prepare the generator for emergencies, and to lubricate its engine, fill its battery, and check its operation.

- Seasonal Maintenance Preparations: Depending on the season, tweak your maintenance routine. In winter, change to winter-grade oil, check the coolant’s antifreeze concentration. In summer, check the cooling system more frequently to avoid overheating.

When you adhere to the recommended preventive maintenance schedule for your MTU Generator, you will not only ensure its reliable operation, but you will also help it to be as efficient as possible over its entire life. As long as it runs, it should not let you down – except for the fact that neglect can sometimes lead to failure. Prevention is better than cure, and as the saying goes, time spent on corrective maintenance is time you will never recover.

Image Source:https://www.mtu-solutions.com/eu/en/service/preventive-maintenance.html

When to Seek Professional Help

While a solid understanding of mtu generator repair and regular maintenance can solve many issues, there are situations when calling in a professional is the best course of action. Recognizing when professional expertise is required not only ensures the repair is handled efficiently but also protects your investment in the long term. Here’s when to consider expert intervention:

- Complex Electrical Problems: If you encounter electrical issues beyond basic troubleshooting, such as in-depth diagnostics of the alternator or control system, it’s time to consult a professional. Electrical repairs can be hazardous and require specialized knowledge and equipment.

- Major Mechanical Failures: Should your generator suffer from significant mechanical problems, such as engine failure, it’s crucial to seek professional help. These issues often involve complex disassembly and knowledge of intricate engine components.

- Warranty Concerns: If your generator is still under warranty, performing DIY repairs could void the warranty. For repairs covered under warranty, always use authorized service providers to maintain your coverage.

- Lack of Proper Tools or Facilities: Some repairs require specialized tools or a controlled environment that only a professional repair shop can provide. Attempting these repairs without the proper equipment could result in further damage to the generator.

- Selecting a Qualified MTU Repair Service: Look for service centers that are authorized by MTU or have a strong reputation for working with industrial generators. Check for certifications, reviews, and ask for references. A qualified service provider should have in-depth knowledge of MTU generator repair, access to genuine spare parts, and the ability to perform diagnostics and firmware updates.

Remember, while regular maintenance can significantly reduce the need for repairs, there are times when professional expertise is invaluable. Opting for professional service ensures that your MTU generator repair is maintained to the highest standards, guaranteeing reliability and efficiency when you need it most.

Conclusion

Truly understanding how to do mtu generator repair takes more than a week, more than a certificate, and more than a stake in the power industry. It’s about getting to know the duties and responsibilities of one of the most crucial components of a power system, inside and out. We’ve gone through this process all the way from gaining an understanding of what MTU generator repair is to preventive care and maintenance, what issues to watch out for, how to get ready, and exactly how to do the job step by step. The process is outlined in detail above. Check out our other generator repair posts, if you wish.

As Thomas Edison said: ‘Most of us are familiar with the tremendous amount of work that goes on to accidentally stumble onto opportunity. But once in a while, just once in a while, you stumble while you’re working – and find opportunity.’ The work required to learn how to repair and maintain a mtu generator will pay off handsomely in reliability, efficiency and long-term cost savings. Following the advice in this guide will help ensure that your MTU generator repair are available when you need them, avoiding expensive downtimes and keeping your equipment operating its best well into the future.

In summary, learning to repair an MTU generator might sound unmanageable and nerve-racking at first, and it can be, but in the end, it is priceless. Adopting a lifelong learning behaviour, a sense of detail and an approach to proactive maintenance could turn headaches into opportunities for growth and reliability. The ultimate goal should be not only to solve them on the spot as they occur, but also predicting and preventing them from happening before it’s too late. Your MTU generator repair will be only as good as the amount of care you put into it.

References

MTU Solutions provides a comprehensive range of tools and downloads, including PS-SPEC, a power system sizing and specification program, and DiaSys, a diagnostic software, which are essential for anyone involved in the design, application load analysis, or installation of generator sets.

W.W. Williams stands out as a notable service provider for MTU generators, offering a wide range of services from repair to maintenance for heavy equipment and MTU engines. They emphasize their long-standing expertise in the field and commitment to providing solutions that meet customer needs, including emergency response and customized service agreements.

Generator Power in Australia highlights their comprehensive service offerings for MTU generators, encompassing everything from general inspections and troubleshooting to lubrication service, cooling system service, and more.