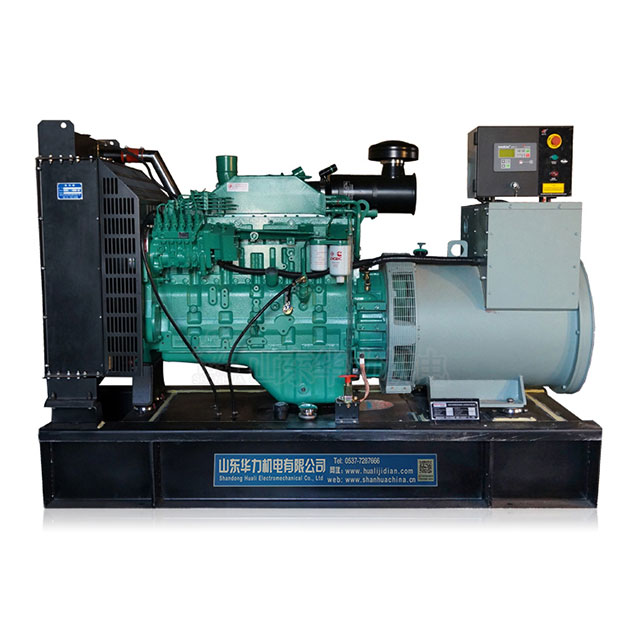

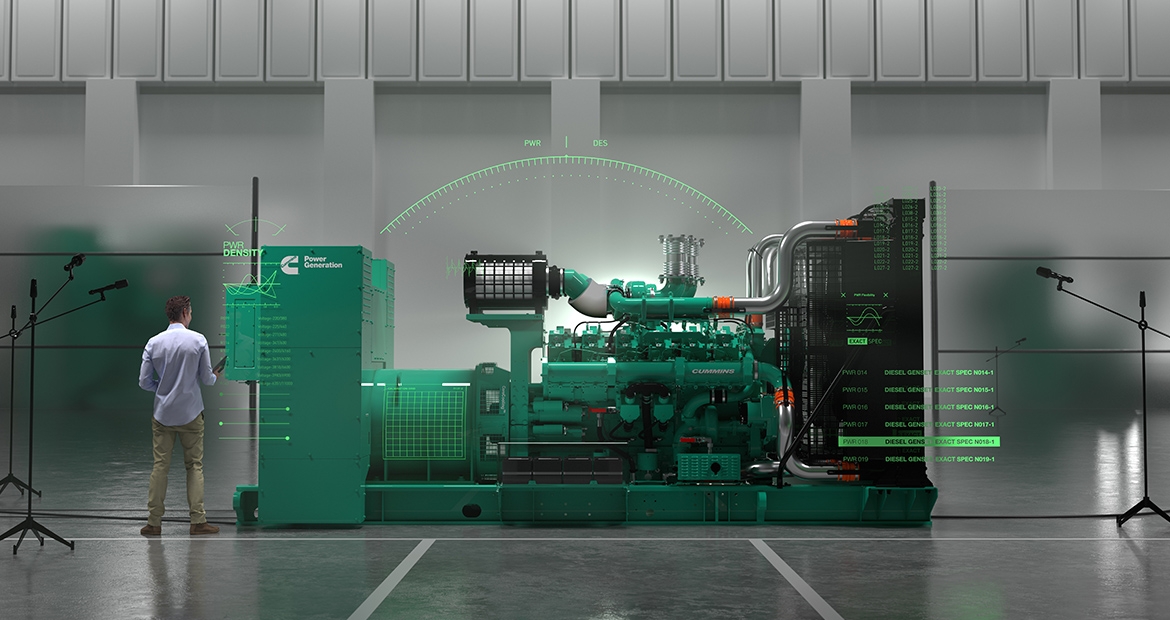

Cummins Inc. is globally recognized as a powerhouse in the field of standby generators, renowned for their reliability and advanced engineering. However, even the most robust systems can encounter issues. Understanding common faults in Cummins standby generators is crucial for effective maintenance and ensuring their longevity. This article aims to shed light on prevalent Cummins standby generator problems, offering practical troubleshooting solutions to help owners and technicians maintain optimal performance.

The significance of diagnosing and resolving generator faults cannot be overstated. Not only does this knowledge prevent prolonged downtimes, but it also extends the life of the equipment, ensuring that it delivers power reliably when needed most. By addressing common and specific issues, we provide a comprehensive guide to help users navigate the complexities of generator maintenance and repair, reinforcing the importance of proactive care and knowledgeable intervention.

Identifying Common Faults in Cummins Standby Generators

Start-up Failures: Causes and Quick Fixes

One of the most frequent issues with Cummins standby generators is start-up failures. These problems often stem from battery issues, such as insufficient charge or poor connections, and can be exacerbated by colder climates where battery performance typically declines. To address this, ensure that the battery is fully charged and connections are clean and tight. Checking and replacing old batteries before they fail can prevent these issues.

Power Output Issues: Symptoms of Underperformance and Potential Culprits

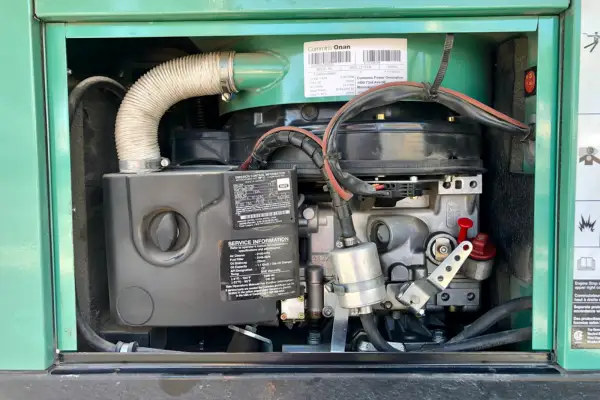

Underperformance in power output is another common concern, which may manifest as the generator failing to handle the expected load. Potential causes include clogged air filters, fuel supply problems, or issues with the exhaust system. Regular maintenance checks can help identify these problems early. Cleaning or replacing air filters and ensuring the fuel system is free of obstructions and leaks are essential steps in restoring full power functionality.

Overheating Problems: Why It Happens and How to Prevent It

Overheating in Cummins generators can occur due to several factors, including an overloaded generator, blocked air passages, or a malfunctioning cooling system. It’s crucial to ensure that the generator is not running beyond its capacity. Keeping the generator and its surroundings clean from debris will help maintain proper airflow, and regularly checking the coolant levels will prevent most overheating issues.

By identifying and addressing these common faults, operators can significantly reduce downtime and extend the service life of their Cummins standby generators. Regular checks and timely maintenance are key strategies in ensuring that these generators remain reliable sources of power.

Specific Cummins Standby Generator Problems

Battery Malfunctions: Diagnosis and Maintenance Tips

Battery issues are a primary culprit in generator failures. For Cummins standby generators, battery malfunctions may present as slow cranking or failure to start. Regular testing and charging are imperative. Use a voltmeter to check the battery’s voltage level; it should typically read around 12.6 volts when fully charged and not under load. Replacing batteries every three to five years, or as indicated by a drop in performance, is a proactive measure to prevent failures.

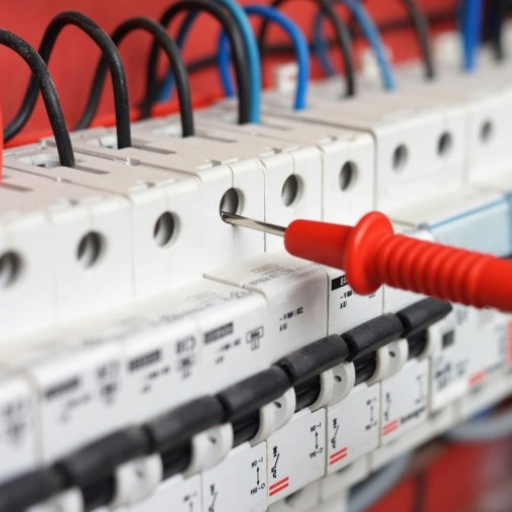

Control Panel Errors: Common Error Codes and Their Meanings

The control panel on a Cummins generator is the brain of the operation, providing crucial information about performance and potential problems. Error codes can signal specific issues, ranging from low oil pressure to failed start attempts. Each code has a specific meaning, often detailed in the generator’s manual. For instance, a common error code like ‘Overcrank’ points to a failure in starting after several attempts, suggesting battery or fuel issues. Keeping a manual handy for quick reference or consulting Cummins’ digital resources can help in swiftly diagnosing and addressing these errors.

Fuel System Issues: How to Detect and Resolve Fuel-Related Problems

Fuel system complications can severely impact generator performance, manifesting as poor engine running or starting issues. Regular inspection for leaks, sediment build-up, and blockages in fuel lines is crucial. For diesel-powered units, ensuring that the fuel is free of contamination by water or debris is vital, as these can lead to significant engine damage. Implementing a routine of using only clean, fresh fuel, and adding stabilizers if the generator is not used frequently, will help maintain the integrity of the fuel system.

Addressing these specific problems requires a keen eye and adherence to a regular maintenance schedule. By focusing on these critical areas, users can significantly enhance the reliability and efficiency of their Cummins standby generators, ensuring they are ready when needed most.

Step-by-Step Troubleshooting Guide

How to Safely Assess and Diagnose Issues

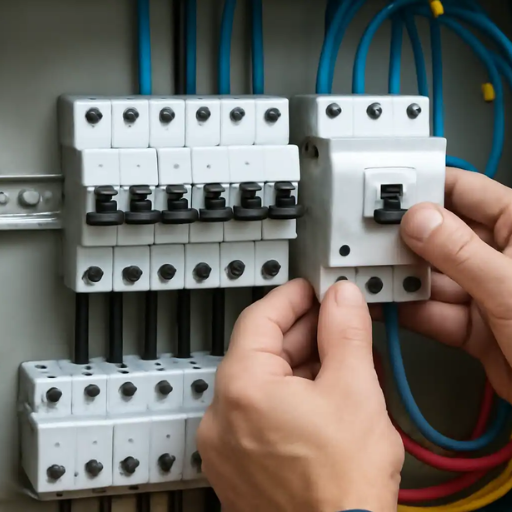

Safety is paramount when diagnosing issues with Cummins standby generators. Before beginning any troubleshooting, ensure the generator is turned off and disconnected from any power source. Wear appropriate safety gear, such as gloves and eye protection, especially when checking electrical components. Begin by visually inspecting the generator for any obvious signs of damage or wear, such as frayed wires, leaks, or corrosion. Use a multimeter to check electrical connections for continuity and proper voltage levels, ensuring all readings align with the specifications outlined in the generator’s manual.

Detailed Steps to Resolve the Most Frequent Operational Faults

- Battery Check: If the generator fails to start, first check the battery’s voltage and connections. If the battery is below 12 volts, it may need charging or replacement.

- Fuel System Inspection: For issues related to starting or power output, inspect the fuel lines for blockages or leaks. Replace fuel filters and ensure that the fuel is fresh; stale fuel is a common cause of generator malfunctions.

- Cooling System: To address overheating, check the coolant levels and refill if necessary. Inspect the radiator and clean any debris obstructing the airflow.

Tips on When to Call a Professional for Help

While many issues can be resolved with basic troubleshooting, some problems require professional expertise, especially when dealing with complex engine faults or electrical failures. If the generator:

- Continues to display error codes after basic troubleshooting,

- Emits smoke or unusual noises,

- Fails to start despite all basic checks and corrections, it’s time to call a certified Cummins technician. Professional servicing is also recommended for routine maintenance or when handling warranty issues to ensure the work is done correctly and safely.

This guide aims to empower owners with the knowledge to handle common issues but underscores the importance of professional intervention when necessary to maintain the generator’s safety and operational integrity.

Preventative Maintenance and Best Practices

Preventative maintenance is essential for ensuring the reliable operation of Cummins standby generators. Regular checks and routine care can prevent many common issues and prolong the lifespan of your generator.

Routine Checks to Avoid Common Faults

Regular visual inspections and functional tests should be conducted to ensure that all components of the generator are in good working order. Check for:

- Leaks: Look for oil, fuel, or coolant leaks which could indicate seal or gasket failures.

- Corrosion: Inspect battery terminals and electrical connections for signs of corrosion, which can impair functionality.

- Wear and Tear: Examine belts, hoses, and other rubber and plastic components for cracks or brittleness.

Scheduled Maintenance: What to Do and When to Do It

Adhere to the maintenance schedule recommended by Cummins, which is typically detailed in the user manual. Key maintenance tasks include:

- Oil Change: Perform oil changes according to the manufacturer’s specifications, generally after every 200 hours of operation or annually.

- Filter Replacement: Replace air, fuel, and oil filters at the recommended intervals to ensure clean and unobstructed flow.

- System Checks: Regularly test the battery, charging systems, and transfer switch to ensure they activate properly during power outages.

Importance of Using Genuine Parts and Authorized Service Providers

Using genuine Cummins parts ensures compatibility and reliability, which non-original parts may not guarantee. Genuine parts are designed to meet specific operational standards and are often covered by a warranty. Additionally, servicing your generator through authorized Cummins service providers ensures that the technicians handling your equipment are trained and certified by Cummins, providing peace of mind that the service and parts are up to standard.

This approach to preventative maintenance not only helps in keeping the Cummins standby generator in optimal condition but also safeguards your investment by ensuring that the generator is ready to operate efficiently and effectively when needed, thereby minimizing potential downtimes.

Conclusion

This article has explored the common and specific issues associated with Cummins standby generators, providing clear guidelines on identifying, troubleshooting, and resolving these problems. Regular maintenance, alongside proactive checks and repairs, plays a crucial role in ensuring the reliability and longevity of these essential power solutions.

It is important for owners and operators of Cummins generators to stay vigilant about routine maintenance and to respond swiftly to any signs of trouble. By doing so, they can ensure that their generator remains a dependable source of power during critical times. Additionally, adhering to the recommended practices, such as using genuine parts and consulting with authorized service providers, further enhances the generator’s performance and safety.

In summary, maintaining a Cummins standby generator involves a combination of technical knowledge, regular maintenance, and the awareness to seek professional help when necessary. Following these guidelines will help minimize downtime and extend the operational life of the generator, ensuring it performs optimally when you need it most. Through regular care and preventive measures, users can confidently rely on their Cummins generator to provide a steady and reliable power supply.

FAQs: Common Questions About cummins standby generator problems

What are the most common start-up problems with Cummins standby generators?

The most frequent start-up issues include battery failure, fuel system problems, and control panel errors. Ensuring the battery is fully charged, the fuel quality is high, and the control panel settings are correct can mitigate these issues.

How can I prevent my Cummins generator from overheating?

Overheating can be prevented by ensuring the generator is not overloaded, maintaining clear ventilation paths, and regularly checking and refilling coolant levels. It’s also important to remove any debris from the air intakes and exhausts to keep air circulation unimpeded.

What should I do if my generator shows error codes?

First, consult the generator’s manual to understand the meaning of the code. Common codes may relate to low oil pressure, high engine temperature, or charging faults. Address the specific issue as suggested in the manual, or contact a certified technician if the solution is not straightforward.

How often should I perform maintenance on my Cummins standby generator?

Cummins recommends conducting routine maintenance according to the schedule provided in your generator’s manual. Generally, this includes regular oil and filter changes, system checks, and annual professional inspections.

Is it necessary to use only Cummins parts for replacements?

Using genuine Cummins parts is advisable to ensure compatibility and reliability. Genuine parts are designed to meet specific operational standards of Cummins generators and are often essential for maintaining a valid warranty.

By regularly addressing these common questions and concerns, owners of Cummins standby generators can significantly enhance the reliability and efficiency of their equipment, ensuring it operates smoothly when needed most.

Related literature

- Osburn Services – Cummins Generator Troubleshooting: This guide provides a comprehensive overview of troubleshooting steps for common issues, including checking oil levels, air filters, and spark plugs, as well as inspecting the exhaust and cooling systems to prevent overheating. The article also offers advice on maintaining the fuel injection system and regular maintenance practices to ensure long-term reliability. Read more at Osburn Services.

- Mastering Cummins Generator Troubleshooting – Osburn Services: This article emphasizes safety precautions and offers a step-by-step approach to identifying common problems such as issues with starting, automatic shutoff, and power output. It stresses the importance of regular maintenance and professional assistance for more complex repairs. Explore more on Osburn Services.

- Cummins Generator Fault Codes List – RV and Playa: This resource details the various fault codes for Cummins generators, categorized by the nature and severity of the issues, ranging from critical operational faults to non-critical status indicators. The guide explains how to address each fault code and when professional help is required. Learn more at RV and Playa.

- Common Generator Problems with Troubleshooting Tables – Powered Outdoors: This article provides troubleshooting tables for frequent generator problems, including issues with starting, fuel supply, and component failures like air and fuel filters. It offers practical tips for resolving each issue, emphasizing the importance of proper maintenance. Detailed guide available at Powered Outdoors.

- Most Common Home Generator Problems & Solutions – AirPlus: This piece discusses typical issues with home generators, such as battery failures, stalling during operations, and coolant problems. It offers actionable tips for each problem and underscores the importance of routine maintenance to prevent common issues. Read further at AirPlus.