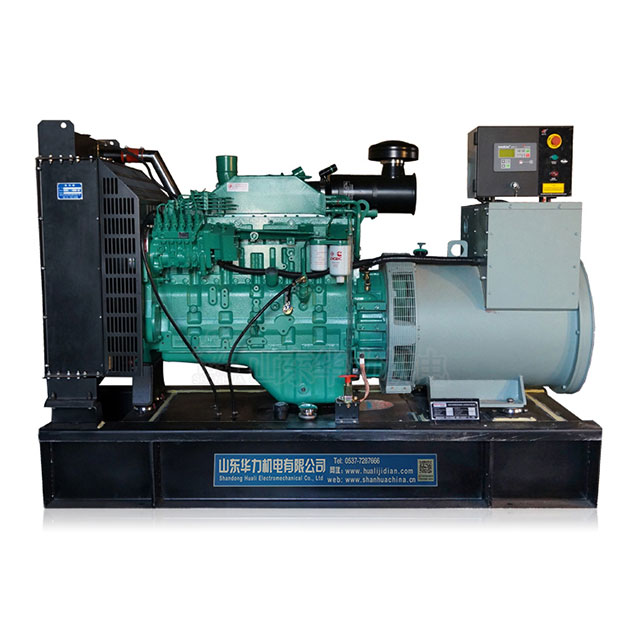

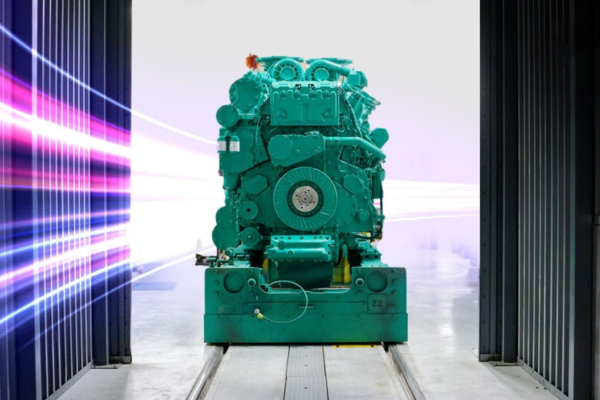

Generators that are reliable enough to power a multitude of applications worldwide.The world leader in power supply is Cummins generators, a versatile, durable and innovative line of generators selling a multitude of power applications worldwide. With a legacy that spans 90 years since the inception of Cummins-diesel company in 1919 by its founder Clessie Cummins in Columbus, Indiana, the power leader has expanded to its current status from a modest company to a multinational power solutions provider, distributing advanced diesel, natural gas, and hybrid power generators.

The story of the leaping cummins generators represent the succesfull journey of the company through the years with a model clearly engineered for superior performance, quality and innovation, demonstrating Cummins’ concept of sustainability and achieving a balance between people, planet and profit. Throughout the history of the company, Cummins has always been at the forefront of technology innovation, introducing groundbreaking technologies to increase efficiency, sustainability and performance of its generators. The excellence of quality behind every single unit produced is of utmost importance for the company, enabling Cumins to maintain its position of power and reliability on the ever-changing needs of the current global market.

Is an example of Cummins’ proud record of manufacturing operations serving customers around the globe. Cummins has manufacturing facilities worldwide. This is part of a strategy that combines regional market insights, learned experiences and resources to produce the best quality generators to stand the test of time. Manufacturing globally enables cummins generators to directly serve its global customer base on the sites.

The closer we pay attention to the where of Cummins generators, the more it becomes clear that the company’s global presence is the key to its ability to innovate – and power – our world. By powering everything from hospitals to refineries to cell phones and laptops, Cummins generators work to provide efficient mechanical power where and when it is needed, thanks to the company’s global manufacturing footprint.

In the subsections that follow, we will look at the main manufacturing countries and regions, where cummins generators are made, some of which have played an eclectic as well as politically significant role in the making of cummins generators. Elvis has left the building. from its core cummins generators made in the USA to its global manufacturing locations worldwide, the tale of where Cummins generators are made is a story of global cooperation, innovation and an unparalleled dedication to top quality.

Cummins Generators Made Manufacturing Locations

cummins generators global manufacturing commitment to is part of the corporate soul of the company, and reflects a strategic manufacturing approach in the global arena, from United States and UK to China and India, and many more countries. On one hand, the word of manufacturing illustrates Cummins’ position as the world leader in power generation. On the other hand, the definition provides the aspect of maintaining manufacturing continously to seriously satisfy globally diversified clients.

Global Manufacturing Strategy

cummins generators operates in a philosophy that emphasises engaging local talent, local resources and local market knowledge, which translated to the setting up of factories in various critical markets and locations world wide. The production of cummins generators is done in dummy production facilities strategically located in those countries and markets which are customers, the majority of them are located in Europe and China, to shorten the distances the generators have to travel in order to reach their customers, with its aim to solidify Cummins comprehensive marketing presence!

Key Countries and Regions

Cummins has concentrated manufacturing investments across diverse continents – North America, Asia and Europe – each home to a specific strategic advantage for a Cummins supply chain and customer base.

- North America: The United States continues to be a key location for Cummins, with up-to-date manufacturing plants and research and development facilities. This ensures consistency and contemporary technology in their generators.

- Asia: Major Cummins manufacturing facilities are found in countries such as India and China, where the companies benefit from well-established manufacturing infrastructures, well-trained workforces, and access to nearby quick-growing markets that need more reliable power solutions.

- Europe: Europe’s standards for emissions and energy efficiency pair perfectly with Cummins’ commitment to environmental stewardship, making it an obvious region for producing generators that meet the highest possible standard. Cummins’ UK and European facilities serve the EMEA (Europe, Middle East and Africa) market.

Emphasizing Diversity in Production Locations

The diversity of cummins generators made production locations is a testament to the company’s global outlook. By manufacturing generators in different regions, Cummins can cater to specific market requirements, adhere to local regulations, and mitigate risks associated with geopolitical tensions or supply chain disruptions. This geographical diversification also allows Cummins to tap into local engineering talents and technological advancements, further enhancing the quality and competitiveness of its generators.

cummins generators made global manufacturing footprint is a key element of its success, enabling the company to maintain its position as a leader in the power generation industry. By strategically locating its manufacturing facilities around the world, Cummins ensures that it can meet the evolving needs of its global customer base with efficiency and agility. This commitment to global manufacturing and supply chain excellence is what enables Cummins to deliver reliable, high-quality generators that power essential services and industries worldwide.

United States: The Heart of Cummins Generators Made Production

The US is not just the country where cummins generators are made, it is still at the very centre of operations when it comes to Cummins’ global generator production efforts. While the history of innovation and the mastery of manufacturing have long been at the forefront of the Cummins US operations that support operations around the world, Cummins supports its customers around our world with its range of power solutions.

Facilities Across the States

The company’s manufacturing footprint in the US is widespread, with plants located in multiple states, making use of the most contemporary manufacturing technologies and staffed by teams of professionals who are dedicated to building high-quality generators. The company’s hometown of Indiana continues to be a cornerstone of Cummins’s sprawling manufacturing network, with multiple major facilities located there.

Innovation and Design

As much as these U.S facilities make generators, they are also places of research and development (R&D), where Cummins engineers and designers strive to design and develop new ways of making better generators through improved efficiency, reduced emissions, and longer run times. The result is a more reliable product that matches customers’ needs, not only in the US, but throughout the world.

Contributing to Local and National Economies

cummins generators made manufacturing operations in the US contribute mightily to the local and national economies by providing jobs and skill-building opportunities, and working with local suppliers, thus helping to advance, grow and sustain local and national economies. This mutually beneficial relationship between Cummins and its host communities is a testament to the company’s commitment to practice global corporate social responsibility and to be a good neighbour.

A Foundation for Global Success

The US serves as a headquarters for its global operations, providing the manufacturer with the stability and resources to be a leader in the global power generation sector. Technological innovations from its US facilities often set new industry standards.

Its US operations exemplify its commitment to manufacturing excellence, innovation, and community, and an integrated approach to modern manufacturing, manufacturing for sustainability, and a culture of manufacturing excellence. These operations represent the future of not only the generators being produced at facilities such as Columbus, but also Cummins’ commitment to it. These contributed to making Cummins a formidable company in manufacturing accessories and generators manufacturing it. This dedication represented its presence in Columbus for the foreseeable future, and for a long time to come.

Global Footprint: Cummins Generators Made Around the World

Cummins manufacturing footprint now spans the globe in pursuit of expanding its reach, positioning itself simultaneously as a globally influential supplier of generators. The decision to expand manufacturing abroad instead of simply opening warehouses is significant because Cummins acknowledges the importance of being a truly global power supplier of generators: manufacturing globally fosters Cummins’ ability to become a global influence, keeping them connected to the needs of every world market.

Strategic Importance of Global Manufacturing Sites

While cummins generators can be produced at various different specialist plants, the cummins generators made international facilities are the strategic locations in this global network of factories. What makes them strategic is that they are not randomly chosen, but are located in locations of strategic geographical importance: close to a large market, or in proximity of particular global shipping routes, or in locations which make it easier and cheaper for cummins generators to access a given part of the global market. This is what we mean by strategic locations. Another important factor, but not the main reason for having these manufacturing sites is for cummins generators to directly follow and trace regional regulations, which can differ across regions around the world.

Europe: A Hub of Innovation and Quality

European manufacturing plants turned out not only robust and quality products, but pioneering innovations as well Cummins has two major manufacturing and RD hubs in Europe in the form of the Untied Kingdom, where the company manufactures its generators to the highest pollution and energy-efficiency standards, which pay great dividends in the innovative European market.

Asia: Meeting the Demand of Fast-Growing Markets

For Cummins, the fast-growing Asian economies represent a key opportunity. Not just because India and China are growing wealthy rapidly, and because much of that new-found wealth will be spent on reliable power. The Indian and Chinese facilities of Cummins produce not only generators for their local consumers, but also directly contribute to the needs of the Cummins supply chain.

Commitment to Local Markets

signs emphasise that cummins generators’ approach to global manufacturing is rooted in the belief that ‘we serve local markets best by manufacturing where we sell.’ John Binz, plant director in Charleston, South Carolina, told me that manufacturing generators near the points of sale enables customisation to fit local ‘needs and specifications’ and to ensure ‘our customers keep power on at home and abroad’. For Cummins, local manufacturing means access to local and national markets, ‘as well as tapping into local talents, innovations and manufacturing best practices’. On the plant walls, leading up to.and underneath the main sign, are phrases that underscore Cummins’s role as an innovation-driven solutions provider. These phrases tie Cummins’s commitment to global quality standards with its local pivot to market assessments and insights. It is a pivot that promises a meaningful local knowledge and access to generators and related products that are both global in their consistency and locally relevant for market demands.

A Worldwide Network of Excellence

cummins generator manufacturing global footprint is an important part of our success in becoming the single global leader in the design, manufacturing, distribution and service of power generation equipment. Our international facilities help provide both operational efficiencies and a higher level of responsiveness to the needs of our worldwide markets. Through innovation based upon the diverse talents and ideas we see in our global manufacturing footprint, Cummins is able to deliver dependable power wherever you need it, whenever you need it.

The presence of Cummins around the world is not purely about expanding the business; it is about enhancing lives, industries and communities through delivery of power at its best. As Cummins grows and opens up new markets across the globe, it is staying true to its values nurtured across 100 years, when it emerged as a trusted name in power generation, and it shows no signs of slowing down.

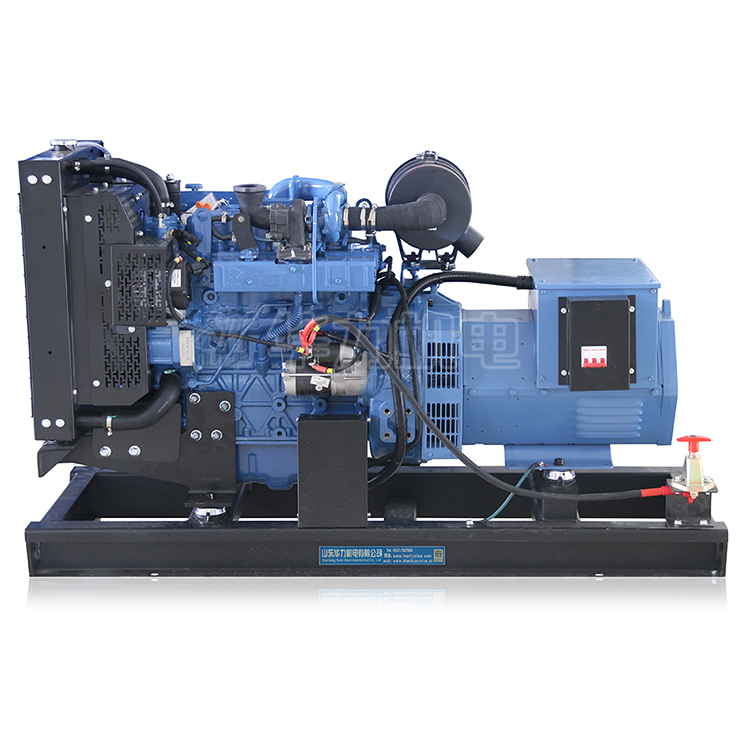

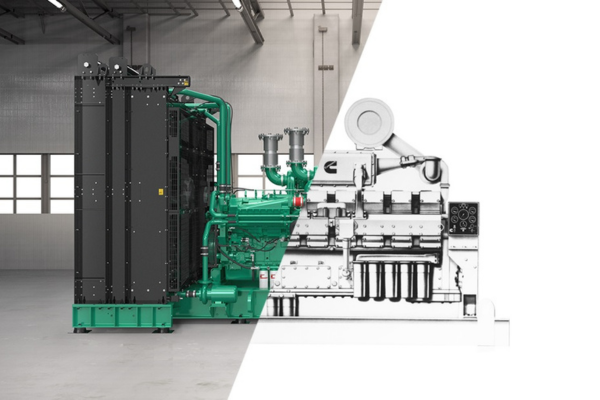

The Manufacturing Process: How Cummins Generators Made

The production of cummins generators made is a testament to the company’s engineering prowess and commitment to quality. From the initial design to the final assembly, each step in the manufacturing process is meticulously planned and executed to ensure that every Cummins generator meets the highest standards of reliability and performance.

Design and Innovation

The journey of a cummins generators made begins with its design. Cummins’ engineering teams across the globe collaborate to innovate and refine generator technologies, focusing on efficiency, durability, and environmental sustainability. Using advanced computer-aided design (CAD) tools, engineers simulate and test various aspects of generator performance, from fuel consumption to emission levels, ensuring that the final product can withstand the rigors of its intended application.

Component Manufacturing

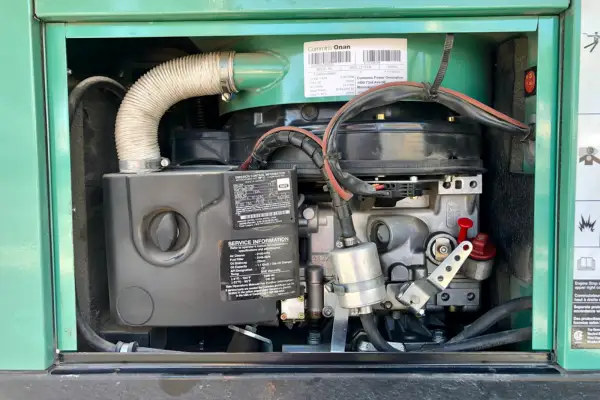

Once a design is finalized, the manufacturing process moves to the production of components. Cummins operates several specialized facilities dedicated to the manufacturing of key generator components, such as engines, alternators, and control systems. These components are produced using state-of-the-art manufacturing technologies, including precision machining, robotic welding, and automated assembly lines, to achieve high levels of accuracy and consistency.

Assembly and Testing

With all components manufactured, the assembly of the Cummins generator begins. This process is carried out at Cummins’ assembly plants, where skilled technicians meticulously put together each part of the generator. The assembly process is characterized by strict quality control measures, ensuring that every generator meets Cummins’ standards of excellence.

Before a Cummins generator leaves the factory, it undergoes rigorous testing. These tests simulate a variety of operational conditions to ensure the generator’s performance, reliability, and safety. Only after passing these tests does a Cummins generator receive the final seal of approval, ready to be shipped to customers around the world.

Quality Control and Innovation

cummins generators made manufacturing plants are not just production facilities but centers of quality control and innovation. The company invests heavily in research and development, continually seeking ways to improve the manufacturing process, reduce waste, and enhance the overall quality of its generators. This commitment to innovation ensures that Cummins can respond effectively to the evolving needs of the market, incorporating the latest technologies into its generators.

Sustainability in Manufacturing

Cummins generators made is deeply committed to sustainability in its manufacturing processes. The company has implemented various initiatives aimed at reducing its environmental footprint, such as minimizing energy consumption, reducing emissions, and recycling waste materials. By integrating sustainable practices into its manufacturing operations, Cummins demonstrates its dedication to protecting the environment while delivering high-quality power solutions.

The manufacturing process of Cummins generators is a complex and nuanced operation that reflects the company’s dedication to excellence and innovation. From the initial design phase to the final testing, Cummins ensures that each generator is built to perform reliably under the most demanding conditions, embodying the company’s commitment to powering a more prosperous world.

Environmental and Technological Advancements in Manufacturing

Cummins belief in generators manufacturing process of your Cummins generators is based on a twin philosophy of environmental responsibility and technological excellence. This helps them in achieving the international environmental goals as well as assure your source of power in a most efficient performance.

Sustainable Manufacturing Practices

Cummins has integrated dozens of sustainability practices into its plants worldwide to preserve the environment, reduce its footprint and benefit its communities:

- Energy Efficiency: All of Cummin’s plants are equipped with smart energy management systems that help to optimise power usage. This helps Cummins reduce its carbon footprint. Cummins is also installing renewable energy sources such as solar panels and wind turbines to contribute to the cause.

- Waste Reduction: By employing more efficient manufacturing techniques, less amount of waste is produced by Cummins. Additional focus on recyclability and reuse of materials helps to eliminate waste from the landfill and to reduce the use of precious resources.

- Water Conservation: Because Cummins views the availability of water as critical to our future, the company is very careful to use as little water as technically possible by employing state-of -the-art water-treatment and recycling technologies, and returning to the environment water that has been reused.

Technological Innovations in Manufacturing

Technology is a driving force behind Cummins’ manufacturing strategy, and efficiency, quality and customisation are the main benefits Cummins has recently enhanced its technological capabilities by:

- Increasing automation and robotics are helping Cummins produce parts more consistently, so its generators become increasingly high-quality. Additionally, there is a lot of cutting and welding involved in the process.

- Digitalisation and Data Analytics:Digitalising Cummins’ manufacturing so that it knows what’s happening on the shop floor at any time, in any place, has enabled insights into how to improve production efficiency, machine health and reduce waste and costs in Cummins’ supply chain. Data analytics enables ‘predictive maintenance’ to keep Cummins’ products out of repair shops and ‘keeping it running’, and to run a more efficient operation.

- Additive Manufacturing: Cummins examines the potential of additive manufacturing (3D printing) in producing high-complexity components with improved structural qualities and functionality. Not only can it lead to greater efficiency in production, but it can also improve the product design by going beyond the limitations imposed by casting and forging processes. Given the market’s fast-paced nature, this type of flexible manufacturing holds great potential both in making prototypes quickly and in producing spare parts when and where needed.

Future Directions: Embracing Renewable Energy and Smart Technologies

In the future, Cummins is committed to bringing renewable energy and smart technologies deeper into its manufacturing operations. For example, the company is developing generators that can use alternative fuels, such as hydrogen and biofuels. It is also exploring the use of Internet of Things (IoT) technologies to monitor and manage its manufacturing operations in real time.

It’s not just about simply complying with regulations or sourcing a product more efficiently – it’s about driving new standards of sustainability and technological innovation for power generation, looking beyond what companies are required to do by law. Cummins leads not only in power generation today, but also in shaping the plant of tomorrow.

The Future of Cummins Generator Manufacturing

At cummins it’s the same big picture when we start looking smarter about the future: what is changing and what is shaping the industry in terms of innovation. What is sustaining it today and what are the newer energy demands and needs that will come to the forefront on the global playing field.

The future of manufacturing for cummins generators has been influenced by a number of developmental trends and projected needs.

Adapting to Market Trends and Global Energy Demands

Cummins closely monitors energy trends worldwide and what customers are demanding globally With the growth of energy’s digitalisation, reliability and sustainability have become the new generation’s pursuit, and the world’s growing demand for more efficient and flexible power sources has driven the emergence of generators that can seamlessly integrate renewable energy sources into the new energy paradigm. Cummins realises that while the world is progressing swiftly towards a greener future with renewable energy, it will also require high-quality generators for more efficient and flexible power. This is the new trend in power.

Investment in Renewable Energy Solutions

It’s a huge part of our R Britannia cummins generators future strategy,” he says, “is to develop generators that can work on alternative fuels such as hydrogen and biofuels; they have a much lower environmental impact than fossil fuels. The other thing we are looking at is hybrid systems. So combining a conventional generator with solar or wind to create a first-class flexible power source.’

Leveraging Advanced Technologies

Technological innovations will remain central to Cummins’s future manufacturing endeavours. The company is investing in smart manufacturing technologies such as artificial intelligence and the Internet of Things, which are likely to improve efficiency and quality control, and expand the range of generators that can be customised to the exact needs of consumers. These technologies will enable the production of more energy-efficient generators capable of intelligent interaction with the grid and other energy systems, optimising performance for a wide range of operational conditions.

Global Manufacturing Footprint

Here Cummins recognises the value of maintaining a strategic global manufacturing footprint, to service the broadening global customer base properly. Cummins may consider the possibility of expanding its global manufacturing footprint, particularly in emerging markets to be closer to their growing energy demand, cost-wise reasons, to tailor OEM requirements.

Commitment to Sustainability

Sustainability will emphatically remain at the forefront of the cummins generator made manufacturing philosophy, ensuring that we provide an environmentally responsible manufacturing of original equipment and aftermarket parts using manufacturing practices that aim to minimize our carbon footprint and better manage resources, and improve the environment in every community in which we do business.

Powered with a thirst for innovation and driven by a commitment to a cleaner tomorrow, cummins generators manufacturing is poised to continue delivering a wide range of advanced power generation equipment that anticipates the needs of a rapidly changing world. The industry’s progression towards fewer emissions, cleaner energy sources, and expanded technological solutions will help keep Cummins at the technological forefront of advancing clean power development and execution.

Conclusion: Cummins’ Global Manufacturing Excellence

Cummins Inc goes beyond just high-quality power generation equipment – it is a vanguard of innovation, green manufacturing and quality products. From India to China, through the UK, South Africa, South America and the United States, trEine Cummins’ high-performance equipment illustrates its commitment to build responsibly and sustainably, with an eye to the future.

A Tradition of Excellence and Innovation

cummins generating has, longstanding from the base construction to the final arehiving, emphasis on top quality products have made Cummins Generators brands – cummins generator prices is essential position in the industry today.

Embracing Sustainability

While Cummins’ approach to sustainability differs from that of Brown University in many ways, it is noteworthy for its focus on reducing the environmental footprint of its manufacturing business. Cummins has reduced energy use, waste and emissions.

Looking to the Future

Now, the company looks forward to consolidating its position as an industry leader in the power generation market. To meet the emerging needs of its global customers, cummins generators will invest in renewable energy, engage in innovations in advanced manufacturing technologies and expand its global footprint. Cummins generators is looking forward to the future rather than back and wanting to be the best.

Powering a Prosperous World

The Cummins global manufacturing excellence is a proud commitment to a business always powering a more prosperous world: from its production processes to its robust environmental standards and consistent quality, its materials and solutions don’t just serve the needs of today, but the challenges of the very near future. Every part of Cummins’ worldwide operation plays a part in helping the company chart a path to success for years and decades to come. Tomorrow’s industries, communities and generational projects will depend on reliable power.

In conclusion, Cummins’s strategic approach to globally-distributed power generation manufacturing, which prioritises high quality, green technologies and innovative novelties, is complementary to their drive for continuous power. In order to remain at the forefront of the power generators business, Cummins keeps its ear to the ground about market trends and new technologies, while remaining committed to producing more efficient and innovative products with respect for the environment, paving the way to a brighter and more sustainable future across the planet.

References

Cummins Official Website: Start by visiting Cummins’ official website, specifically sections like “About Us,” “Our Company,” or “Newsroom” where they might share details about their manufacturing facilities and operations. Look for pages that discuss their global footprint or provide factory tours and locations.

Industry Reports: Websites like Statista or MarketWatch often publish industry reports that can include manufacturing insights. Searching for “Cummins generators manufacturing locations” on these platforms may yield reports on the power generation sector, including where major companies like Cummins operate factories.

Business News Websites: Platforms such as Bloomberg or Forbes frequently cover major manufacturing and industry news. They might have articles or features on Cummins that discuss where their products are made.

Academic and Professional Journals: For more detailed analyses, Google Scholar and similar databases can provide academic papers and industry studies that examine Cummins’ manufacturing strategies and global operations.

Cummins Investor Relations: The investor relations section of the Cummins website may offer annual reports, press releases, and other documents that detail the company’s manufacturing activities and locations as part of their corporate transparency efforts.