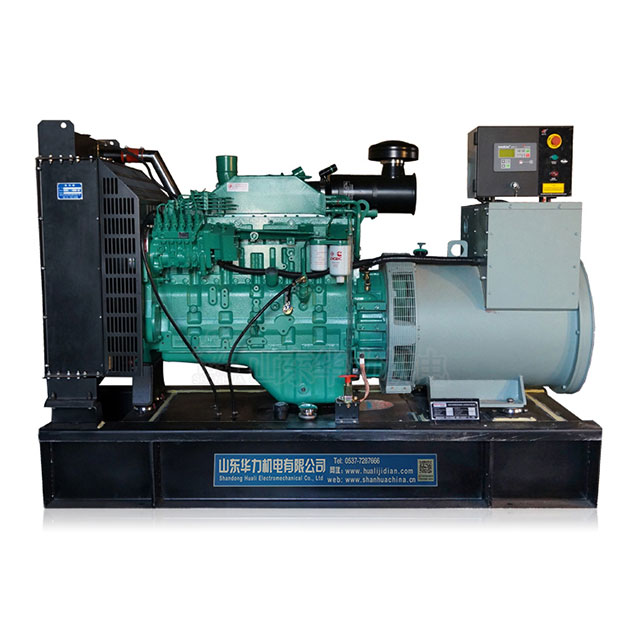

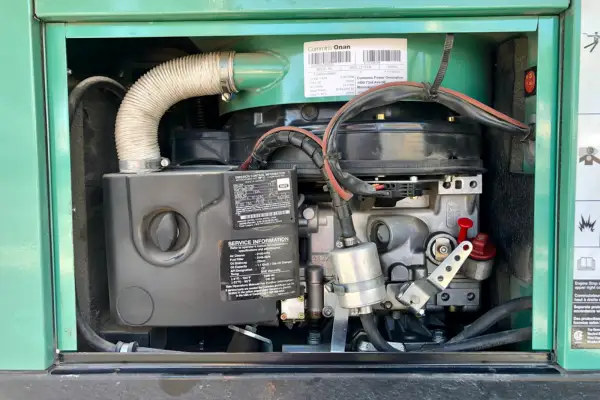

Cummins Onan has risen to its position in the global generator market with its commitment to dependability and continuous innovation. Today, Cummins Onan generators are known for their durability and efficiency, making them ideal for a variety of industries, including recreational vehicles, marine, commercial mobile, residential standby, and portable power applications. The question of where are Cummins Onan generators made becomes significant because consumers care about the location of their products, and knowing where they are being made plays a major role in the quality and availability of power-generating equipment.

The importance of these manufacturing sites cannot be underestimated because Cummins Onan’s generators help to secure critical industries, including hospital power that needs to remain uninterrupted and recreational vehicle power that lets people go on adventures in remote locations. A manufacturer’s decision to make the generators in multiple different countries around the world is not only to make sure that the generators can pass high standards of quality, but also to be able to ship the generators efficiently wherever they are needed. This is also one place where the philosophy of the firm’s founder – Clessie Cummins who started the company in 1919 – can be applied to the present situation. He believed in discovering multifaceted solutions, including positive ways to address the current economic situation.

At a time when questions of where things get made are paramount, Cummins Onan creates a sense of being special by choosing unique places to make its generators. Not just points on a map, Cummins Onan’s places of production represent the brand’s home base for technology development and cutting-edge quality around the world, the heart of its reputation for reliability. Each of the many locations was fitted out with the best systems and best – often foreign – innovations available at the time. Cummins Onan generators were and are not just engines; they have always represented technology, a commitment to improving life. From its home base in Columbus, Indiana, Cummins Onan stepped out into the diverse array of international production centres to become a truly global brand.

The History of Cummins Onan Generators

This is the story of Cummins Onan generators: a story of innovation and quality and a never-ending commitment to excellence. When the company began, it was a small operation that offered an important new product. However, the successor to Cummins Onan’s North Jennings generator plant eventually grew to become a global operation known for its power solutions. Its journey is the story of industrial development and the search for innovation.

What began as a vision of bringing dependable power to an increasingly electrified world on the verge of an industrial revolution, Cummins Onan finds itself more than a century later integrating products into the lifestyles of a global marketplace. The business today demonstrates an ability to maintain value despite various market and technologies shifts that occurred during its lifetime. And it has retained two timeless attributes that have contributed to its success: quality and innovation.

Often, company spokespeople point to Cummins Onan’s innovative nature as the chief reason of its global leadership. ‘Cummins Onan has always been on the vanguard – assimilating new technologies, adapting to market conditions with deft agility, and looking ahead with forward-thinking precogitation,’ declares Emily Robertson, a historian who specialises in industrial developments. Indeed, that innovative aptitude can be seen in Cummins Onan’s history of product development, which is populated with markers of benchmarks that not only built on prior offerings to create more capable generators but also shrank the environmental footprint of the devices.

Quality is not just a mantra at Cummins Onan – it is built into everything that the Company does. Thirty-three years of leadership in the industry; product testing in real world conditions; the green design; coupled with continual upgrading of manufacturing processes: Cummins Onan has not only met industry standards, but has actually gone a step further to create industry standards. ‘Cummins Onan generators are far more reliable and efficient than many other brands, which is a testament to the high standards of quality that are implemented at all levels of manufacturing,’ says Michale Zhao, who has been an engineer for power systems for 20 years.

Where Are Cummins Onan Generators Made?

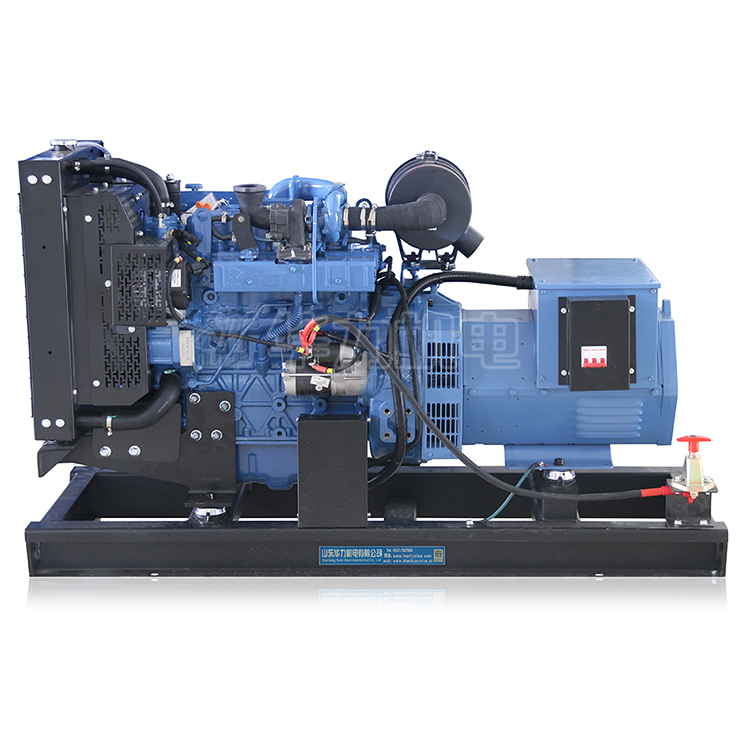

The breakdown highlights the geographical footprint of Cummins Onan generators, which are manufactured across several continents to reflect the brand’s strategy in driving regionalised excellence to excellent quality, efficiency and accessibility. Where are Cummins Onan generators made?

Instead, the company’s manufacturing network spans around the world, with key production set in the United States, Europe and Asia, each location benefiting from its technological know-how, skilled labour and logistical privileges, so that Cummins Onan generators are of the highest quality and globally accessible. The United States, headquarters of Cummins Inc., is host to many of Cummins Onan’s manufacturing facilities. These plants are the pillars of the Company’s production for the North American market, and recognised all over the world for the excellence of their methods of production and adherence to quality standards.

Cummins Onan has a long European history but an American soul. We have facilities here all around Europe that are developing and engineering towards the European markets so that those generators are exactly what we need them to be – part of the rich tradition of engineering here. They have to be robust and reliable, and they have to play according to the many rules of Europe, including some of the most rigorous in the world as far as environment and safety are concerned.

And, deeper in Asia, Cummins Onan facilities serving the Asia-Pacific region and the world are packed with innovative jewels, producing not only the equipment but some of the most critical research and development that this global brand needs and, by extension, the world requires.

His tour of Cummins Onan locations highlighted another way that the company is thinking global and working to make its generators available pretty much anywhere in the world. ‘We manufacture generators on five continents because it has a lot of benefits to the customers and to the supply chain,’ John Carter, a senior executive for Cummins Onan, points out. ‘We’re close to customers because each one of these factories is close to a customer base and can deliver much faster and much more in order to conform to local specs.

The Manufacturing Process of Cummins Onan Generators

Manufacture of a Cummins Onan generator follows a step-by-step process, with each stage of the complex choreography carefully planned and executed with a belief in the brand’s ethos: a dedication to quality, sustainability and technology. It is not just the putting together of parts.

The path that a Cummins Onan generator journeys along from an idea to a finished product starts with design and engineering, with a focus on efficiency, durability and eco-friendliness. Using the latest design software and simulation tools, Cummins Onan engineers design each of its generators for exacting performance and reliability standards.

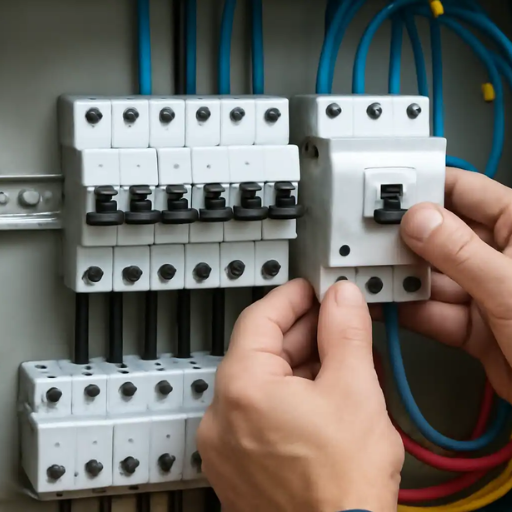

Once designed, the manufacturing phases begin. Components are made in a factory, using advanced manufacturing techniques. High-quality, long-lasting materials are used. Assembly lines, while not always automated, will likely utilise robots to further ensure reliability and redundancy in quality checks.

Quality assurance is built into the manufacturing process through a battery of misuse tests for all power generators produced by Cummins Onan, ensuring that the unit performs correctly, maintains value, and protects its users from physical harm in its intended setting. Extreme environmental conditions and the stresses of everyday grinds are simulated during this testing to ensure Cummins Onan generators can withstand the demands of actual use.

Sustainability and environmental responsibility are built into the manufacturing process from beginning to end: generating minimal waste; selecting materials and processes that are green wherever possible; ensuring that a standard of quality is maintained so that our customers’ generators will operate at maximum efficiency and for an extended period of time. ‘Our manufacturing processes are designed with our sustainability goals in mind,’ says Susan Lee, a plant manager for Cummins Onan.

Innovation is built into every step of Cummins Onan generator manufacturing. Our objective is to keep finding new technologies and manufacturing methods to improve efficiency, reliability and environmental friendliness in the generators we make. Cummins Onan will stay at the front of generator technology by staying on the cutting edge and creating new ideas.

The Impact of Global Production Sites on Cummins Onan’s Distribution Network

This map of the global production sites of Cummins Onan generators shows how these placement of these sites can help the brand to deliver its products in every market rapidly. The strategic location of the sites does not only help Cummins Onan to deliver their generators to each target market in an efficient manner but also allow to the company to plan its logistics and supply chain on a global scale so that their products can quickly reach their market.

A map of the main manufacturing locations for Cummins Onan, one of the world’s largest generators companies, illustrates the company’s geographical presence in the four main continents of the world where a major market is located. These geographical locations help Cummins Onan’s logistics operations: manufacturing the generators closer to end markets lowers shipping times and costs thereby allowing for lower prices and faster service to customers. Proximity to markets also makes it easier for the company to respond quickly and flexibly to fluctuations in the regional demand- supply relations by scaling up and down production as appropriate.

Second, Cummins Onan’s global network of manufacturing sites substantially increases the brand’s supply chain resilience. Supply chain disruptions today can have significant knock-on effects that spread across regions. A range of issues, from regional disruptions to delays in transport or political instability, can affect supply chains in countries around the world. Having multiple production sites helps bring some much needed security through supply chain diversification. ‘Our global manufacturing footprint is one of the foundational elements of a resilient, responsive and agile supply chain,’ says Alex Thompson, a supply chain analyst at the Cummins Onan generators company.

These decisions not only contribute to supply-chain efficiencies and logistical advantages: Cummins Onan chooses such strategic locations partly to tap into local know-how and infrastructure, thereby deepening the reach of the Cummins global knowledge base and helping to drive innovation. When Cummins Onan generators integrates into the local economy, it develops deeper relationships with local suppliers and communities, opening up opportunities for more synergistic processes of material sourcing, workforce development and tech innovation.

Moreover, distribution has a significant environmental impact that Cummins Onan takes into account when deciding where to have its generators made: it makes as much sense ‘environmentally’ to produce a Cummins Onan generator in Ingersoll as it does to build a Dodge caravan there. In Detroit. The wider context Perhaps the most powerful explanation is that even if the ‘transaction costs’ of moving operations to Barbados are simply ignored, there will still be an effect on the hedonistic calculus at the heart of Ippolito’s justification. The implication is that consumers voluntarily choose to do business with companies that have moved their operations overseas. Ippolito assumes that my decision to go to Barbados and not Detroit involves haggling over priorities such as sun and massages versus driving on snowy days. But the context of my decision making is products on a shelf, and there is one company whose products are produced in Barbados and one whose products are produced in Detroit.

The Impact of Manufacturing Locations on Product Design and Innovation

Considering the question ‘where are Cummins Onan generators made’ is about more than just a physical locus of manufacturing. Understanding where Cummins Onan generators are manufactured fundamentally shapes the nature of product design and innovation — this is why Cummins Onan makes a range of generators that are tailored to serve different regions of the world.

Localised manufacturing operations is what enables Cummins Onan to instil its generators with features and functionality that are better attuned with meeting end-market needs and specific requirements. Through this approach, its generators are designed to ensure compatibility with the environmental and regulatory needs of the market and are also better attuned with local consumer sentiment. For example, generators destined for markets with stringent emissions regulations are built with advanced technologies developed expressly to reduce their overall emissions footprint, while those for markets with power grids that are plagued with erratic supply are built with extra emphasis on durability and sustaining operations in the long term.

In addition, its production sites throughout the world serve as innovation hubs, where local teams, often with members from different cultures, six-sigma engineers work side by side with experienced and skilled factory personnel to push the boundaries of innovation in generator technology. Indeed, these Cummins Onan global manufacturing facilities function today as the world’s melting pot, dismantling the barrier of parochialism – a major hurdle to innovation. For examples, the advanced control systems developed for increasing fuel efficiency of its generators in the US is too sophisticated to be developed entirely within China or Europe or any one other country alone. The latter provide the ideas and expertise in manufacturing best practices, whereas the application requires experimenting of these and other ideas – guided by knowledge of local market conditions in the US.

Mexican and Chinese production sites, for example, would play critical roles in ‘accelerating innovation’ at Cummins Onan. It is difficult to imagine, Hayes says, a ‘company as small as Cummins Onan could have invented the technology to make this generator without being able to network into the choices and the problems and the solutions of the entire group of companies’. This remarks is telling, of course, about how Cummins Onan no longer invented anything without external input – in this case, through participation in the company’s wider global production network. Working with suppliers and sister companies abroad, Cummins Onan is able to ‘accelerate innovation’ by rapidly prototyping, testing and refining new technologies. The global naturalisation of production has made Cummins Onan and other global manufacturers innovative beyond the actual centres of invention. These examples illustrate how global firms also become more resilient.

Cummins Onan’s Commitment to Sustainability and Local Communities

The local manufacturing of its generators provided by Cummins Onan is supported by this commitment, as is the protection and positive contribution it makes to the external environment and to the communities surrounding its plants.

At the core of its sustainability is the company’s use of green manufacturing processes, which are intended to minimise waste, reduce emissions, and conserve resources. Cummins Onan’s six generators factories incorporate energy-efficient technologies, recycling programmes and water conservation in its generators factories. The use of solar panels and other renewable energy sources in some of the facilities highlight the brand’s effort to minimise its carbon footprint. ‘Being sustainable and using environmentally-efficient manufacturing processes are not only good for the planet, but also for what our customers expect from us.’ Maria Gonzalez, sustainability officer, Cummins Onan Generators.

Through local development programmes for education, job training and health and wellness activities, Cummins Onan exerts an influence on local communities that goes beyond environmental stewardship. By investing in the communities in which its employees live and work, Cummins Onan creates a feel-good atmosphere that would promote worker wellbeing and engaged families.

Furthermore, if local sourcing is available, Cummins Onan will always consider doing business with the supplier closest to its home plant – a decision that helps local business and spurs economic development in the region in which it is located. In my view, I believe that this procurement strategy not only ensures that Cummins keeps great relationships with suppliers but that it also reduces the amount CO2 being released into the atmosphere as a result of transporting material over extensive distances.

At the same time, the company’s dedication to sustainability and community is apparent in developing and marketing cleaner, more efficient sources of power. And its Cummins Onan generators division is leading the company’s research into – and adoption of – alternative energy sources for generators, such as biofuels and hydrogen, that can dramatically reduce the pollution side of the power equation.

Conclusion: The Future of Cummins Onan’s Global Production

Cummins Onan’s path to enriching communities in 82 countries across the globe, with production of their generators seamlessly integrating into their manufacturing operations, is set to advance in the future under a steady direction of change that will only see their innovation, sustainability and world-wide integration become deeper and broader than ever.

While the statement from Cummins Onan Generators implies that the company’s committment to their high standards in production is reactive, it is in fact a proactive approach to an emerging trend. Given that the world is moving toward sustainable and renewable energy more than ever before, the Cummins Onan generators is poised to become the leading generator of sustainable energy through its innovative research on alternative energy generators and its commitment to sustainable manufacturing. The future of power generators is green. Cummins Onan commits to lead the future. says a senior engineer of the company.

Furthermore, the global footprint of Cummins Onan’s manufacturing plants is not only an advantage for logistics and resiliency of supply chains but also signals the brand’s dedication to global economic and environmental stewardship by continuing to reinvest and to create jobs in local communities, to embrace green technologies, and to invest in power-generation innovation.m

With this, the story of how Cummins Onan generators are made exemplifies the brand’s distinction and leadership in the generator market, providing a story that unites continents, cultures, and communities that work together to deliver excellence. Cummins Onan’s long expedition in global production continues with them moving forward, supplying their unparalleled innovation and quality to the development of a brighter, greener tomorrow.

References

Cummins Onan offers a wide range of generator products, known for their reliability, durability, and high-quality performance, catering to both residential and commercial applications

The company’s generators are particularly noted for being among the quietest in their class, leveraging advanced technology to minimize noise and vibration.

Cummins Inc. itself was founded in 1919 and acquired Onan Corporation in 1986. Onan was established by David W. Onan in 1920 and has since been a pioneer in the power generation industry.

It’s important to note that while Cummins engines are made in various locations worldwide, including a significant presence in China through joint ventures like Dongfeng Cummins Engine Company (DCEC).

Cummins Onan’s reputation for manufacturing durable, reliable, and environmentally friendly generators is well-established. With features designed for safety, efficiency, and easy maintenance