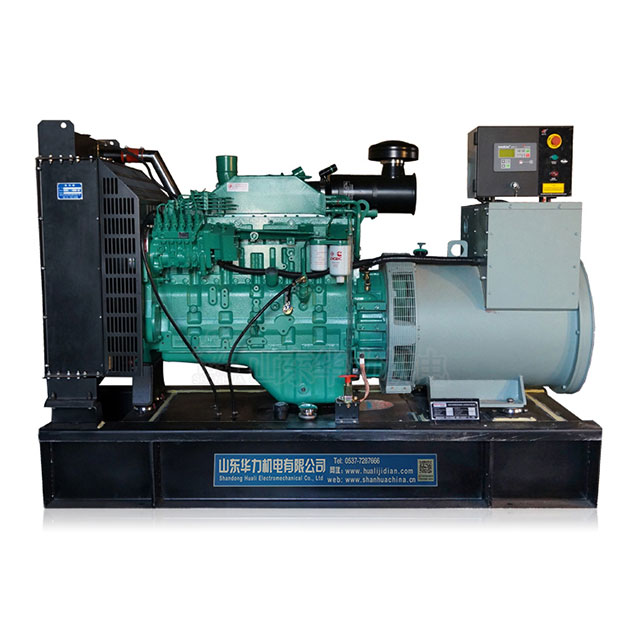

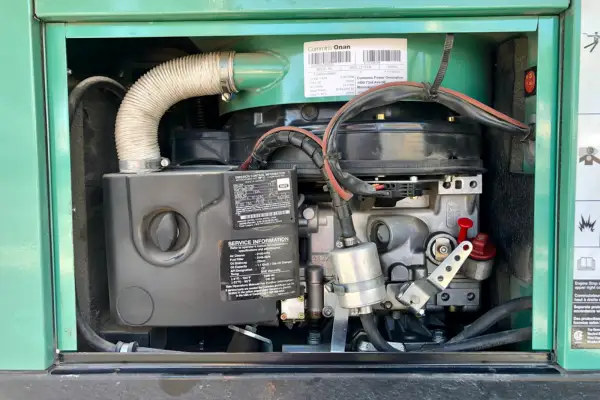

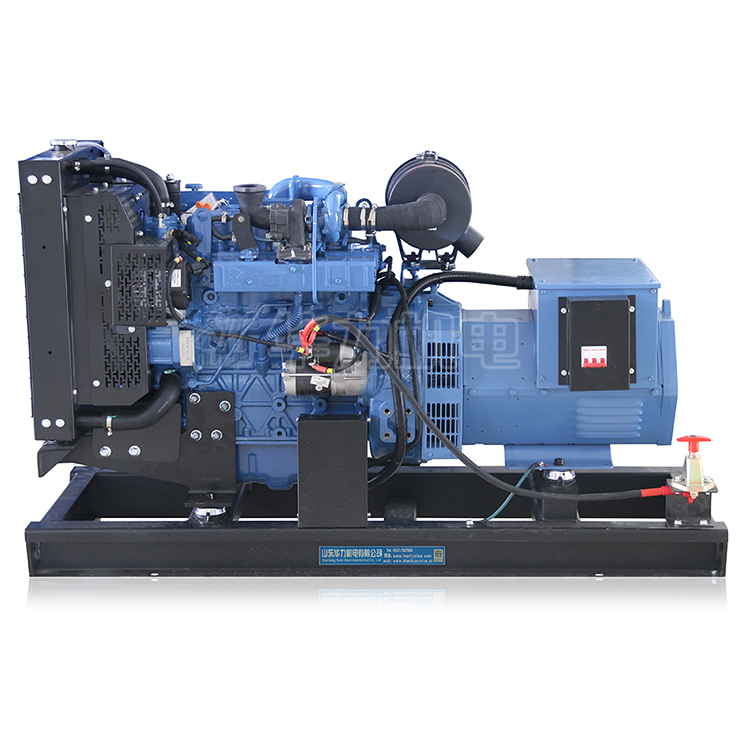

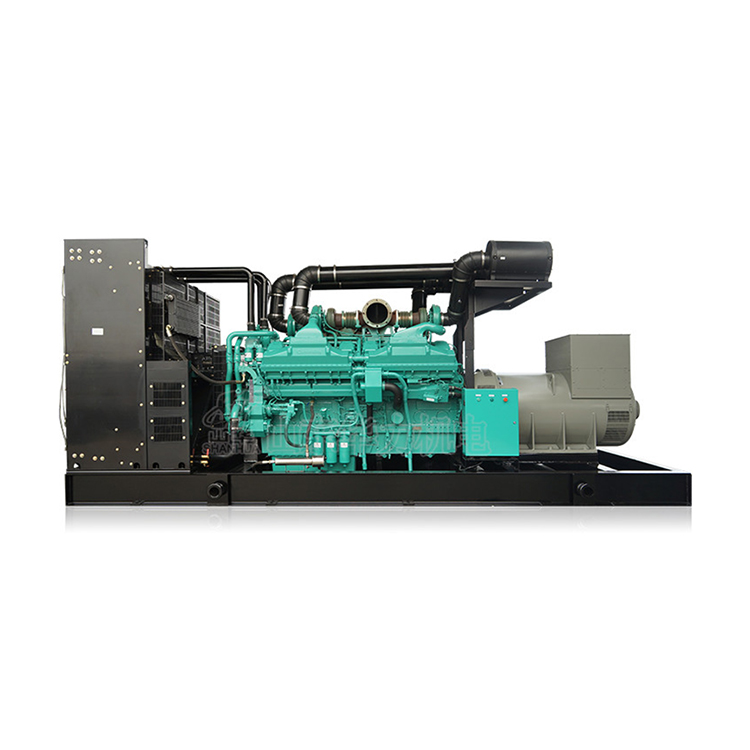

Generators are essential tools, providing power in circumstances where traditional sources are unavailable or unreliable. Among the options on the market, the Cummins 6500 watt generator stands out as a robust and reliable power source. In this article, we aim to equip owners with knowledge and strategies to extend the lifespan of their Cummins generators significantly.

Maintenance isn’t just a responsibility; it’s a necessity that ensures longevity and efficiency. Focusing specifically on the Cummins 6500 watt generator, we will explore a variety of maintenance and operational practices that can help maintain its optimum condition over time. By adhering to the recommendations provided, users can not only prolong the life of their generator but also enhance its performance, ensuring it remains a dependable source of power when needed most.

Regular Maintenance Schedule

Adhering to a strict maintenance schedule is crucial for the longevity of any generator, especially for high-performing models like the Cummins 6500 watt generator. The manufacturer’s guidelines provide a roadmap for keeping the generator in peak condition, which includes routine checks and timely replacements of key components.

Routine Checks

- Oil Changes: Regular oil changes are fundamental to the smooth operation of your generator. Experts recommend changing the oil after every 100 hours of use, or at least once per season, to ensure optimal engine performance. Use high-quality oil that meets the specifications of your Cummins generator to avoid potential damage and wear.

- Filter Replacements: Both the air and fuel filters play critical roles in maintaining the efficiency of your generator. Replace air filters every 200 hours or as they get dirty, and fuel filters every 100 hours to prevent impurities from harming the engine.

- Spark Plug Inspections: Spark plugs should be checked and cleaned regularly to ensure they are functioning correctly. Replace them if they show signs of wear or damage to maintain the engine’s firing accuracy.

Maintenance Tips

- Always turn off the generator and allow it to cool before performing any maintenance tasks.

- Use genuine Cummins parts for replacements to guarantee compatibility and reliability.

- Keep a maintenance log to track service dates, part replacements, and any issues noted during checks. This log can be invaluable for troubleshooting and ensuring that maintenance tasks are not overlooked.

By following these guidelines, owners of the Cummins 6500 watt generator can avoid common maintenance mistakes and ensure that their generator runs reliably for years to come. Remember, regular maintenance is not just about fixing problems as they arise; it’s about preventing them in the first place, thus safeguarding your investment in reliable power.

Optimal Operating Practices

Maximizing the lifespan of the Cummins 6500 watt generator involves more than just regular maintenance; it also requires adherence to best operating practices. Proper operation can significantly extend the life of your generator while ensuring it performs efficiently during crucial times.

Best Practices for Operation

- Proper Load Management: It is essential to operate your generator within its capacity. Overloading the Cummins 6500 watt generator can lead to overheating and unnecessary stress on its components. Aim to use only about 80% of the generator’s rated capacity for optimal performance and longevity.

- Warm-Up and Cool-Down Periods: Before applying load, allow the generator to run idle for a few minutes after starting. This helps the engine and other components to warm up. Similarly, let the generator run without load for a few minutes before shutting it down. This cool-down period helps avoid sudden temperature changes that can cause internal components to wear out prematurely.

Environmental Considerations

- Placement: Always operate the generator in a well-ventilated area to prevent overheating and carbon monoxide buildup. Ensure that the generator is placed on a stable, flat surface to minimize vibration, which can lead to wear and tear over time.

- Operating Temperature: Extreme temperatures can affect the performance of your generator. Whenever possible, operate the generator in a moderately cool, dry place to avoid the stress of high temperatures and humidity.

Adhering to these guidelines not only prolongs the life of your Cummins 6500 watt generator but also ensures it remains a reliable source of power. Understanding and implementing these best practices will help in maintaining your generator’s efficiency and readiness for when you need it most.

Storage Solutions for Longevity

Proper storage of the Cummins 6500 watt generator is as vital as regular maintenance and correct operation to ensure its longevity. When not in use, the way you store your generator can significantly influence its condition and performance when you next need it.

Protective Measures

- Environmental Protection: Store your generator in a clean, dry environment to prevent rust and corrosion. If outdoor storage is unavoidable, use a waterproof cover that is breathable to prevent moisture buildup, which can lead to electrical and engine damage.

- Temperature Considerations: Avoid storing the generator in extreme temperatures. A climate-controlled space is ideal to prevent the oil and fuel from degrading due to temperature fluctuations, which can harm engine components over time.

Maintenance During Storage

- Fuel Treatment: Before storing your generator for an extended period, add a fuel stabilizer to the tank. This prevents the fuel from oxidizing and forming deposits that can clog the carburetor. After adding the stabilizer, run the generator for a few minutes to ensure the treated fuel circulates through the system.

- Battery Maintenance: If your Cummins 6500 watt generator includes a battery for starting, maintain the battery charge by either using a trickle charger or periodically starting the generator during the storage period. This keeps the battery healthy and ensures it will have enough power to start the generator when needed.

These storage practices are critical for keeping your Cummins 6500 watt generator in prime condition and ready to operate at a moment’s notice. By following these guidelines, you can safeguard your investment and ensure that it remains a reliable source of power, ready to perform when you most need it.

Cummins 6500 Watt Generator Troubleshooting Common Issues

Even with meticulous maintenance and proper storage, the Cummins 6500 watt generator may encounter issues that need troubleshooting. Identifying and resolving common problems promptly can prevent minor issues from becoming major complications, thereby extending the lifespan of the generator.

Common Problems and Solutions

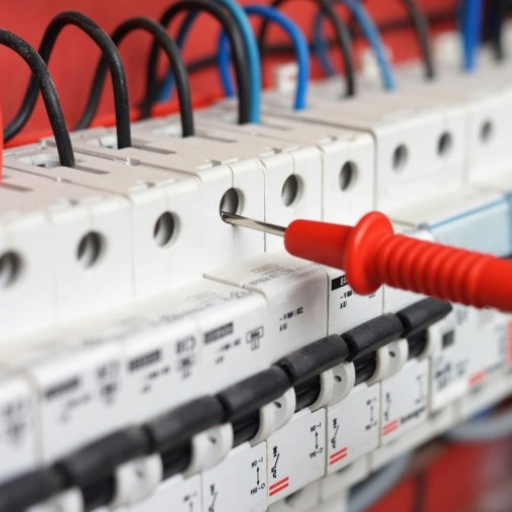

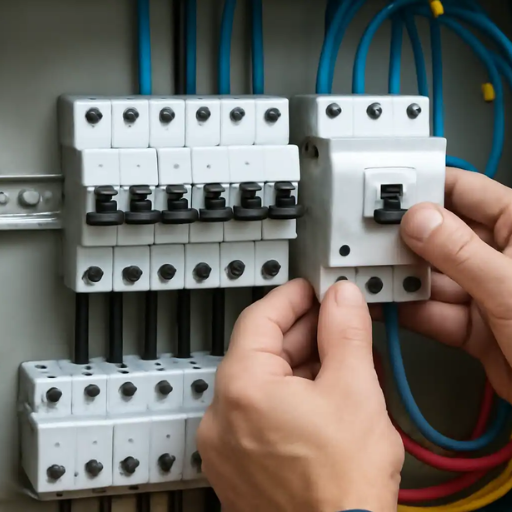

- Electrical Issues: If the generator fails to produce power, check the circuit breakers and reset them if tripped. Ensure all connections are secure and that the generator is not overloaded. Inspect the wiring for any signs of wear or damage and replace as necessary.

- Fuel System Problems: Dirty or clogged fuel filters can restrict fuel flow, causing the engine to stutter or stall. Regularly replacing the fuel filter and using clean, fresh fuel can prevent most fuel system issues. If the generator starts but runs poorly, cleaning the carburetor and checking for any leaks in the fuel lines may be necessary.

- Engine Complications: Common engine issues include overheating, which can be caused by low oil levels or a dirty air filter restricting airflow. Ensure that oil levels are maintained and that the air filter is clean and free from obstruction. If the engine emits smoke or unusual noises, it might indicate internal wear or damage, necessitating a professional inspection.

When to Seek Professional Help

While many maintenance tasks can be handled by the generator owner, some issues require professional expertise. If troubleshooting does not resolve the problem, or if the issue involves internal engine diagnostics or repairs, it is advisable to seek help from a qualified technician. Professional servicing ensures that repairs are done correctly and can help prevent further damage to the generator.

Understanding these common issues and knowing how to address them effectively can significantly reduce downtime and repair costs, ensuring that your Cummins 6500 watt generator remains a reliable asset for your power needs.

Conclusion

Throughout this article, we’ve explored essential strategies to extend the lifespan of the Cummins 6500 watt generator. From adhering to a regular maintenance schedule to adopting optimal operating practices and proper storage techniques, each step plays a crucial role in maintaining the efficiency and reliability of your generator.

Recapping the main points, it’s clear that routine checks such as oil changes, filter replacements, and spark plug inspections are fundamental to keeping your generator in top condition. Additionally, understanding and implementing best practices for operation and storage can prevent common issues and ensure that the generator is ready to perform when needed most.

Investing time and effort into the maintenance of your Cummins 6500 watt generator is not just about prolonging its operational life—it’s about securing a reliable source of power for when emergencies or needs arise. With these practices in place, you can rest assured that your generator will serve you well, offering peace of mind and power security for years to come.

FAQs: Common Questions About Cummins Standby Generator Problems

Owners of Cummins standby generators often have specific questions about maintaining and troubleshooting their equipment. Here, we address some of the most common queries to help users ensure their generators are always ready for action.

Q1: Why does my Cummins generator start but then stop?

A: This issue is often related to fuel problems or sensor malfunctions. Check if the fuel valve is open and ensure there is enough fuel in the tank. Also, inspect the oil level and the air filter, as the generator might automatically shut down if it detects low oil or restricted airflow due to a dirty filter.

Q2: How often should I change the oil in my Cummins standby generator?

A: Oil changes should be performed according to the manufacturer’s recommendations, typically after every 100 hours of operation or at least once per year, whichever comes first. Always use the type and grade of oil specified by Cummins to ensure optimal engine performance and longevity.

Q3: What should I do if my generator is producing unstable or low power?

A: First, check that the generator is not overloaded. Reduce the load if necessary. If the problem persists, it may be due to issues with the voltage regulator or other electrical components. Consulting a professional technician for a thorough inspection and repair is advisable.

Q4: How can I prevent rodents from damaging my Cummins generator?

A: Rodents can cause significant damage by chewing on wires and insulation. To prevent this, ensure the area around your generator is clean and free of debris. Consider using rodent repellents or physical barriers to keep pests away. Regular inspections can also help catch any early signs of rodent damage.

Q5: What are the signs that my generator’s battery needs replacement?

A: Common signs include difficulty starting the generator, slow cranking, or the need to jump-start the generator frequently. Testing the battery’s voltage and inspecting it for signs of corrosion or wear can help determine if a replacement is needed.

These FAQs cover typical issues encountered by Cummins standby generator owners, offering insights into maintenance, troubleshooting, and ensuring continuous, reliable service. By addressing these questions, users can better understand their equipment, leading to enhanced preparedness and operational confidence.

Related literature

- Cummins Inc. – Generator Maintenance Tips: This article from Cummins Inc. offers detailed tips on preventive maintenance essential for reliable starts and extended service life of Cummins generators. It includes routine periodic maintenance advice and emphasizes the importance of maintaining logs and using authorized service providers. Read more on Cummins’ official site

- Generatorist – How to Easily Tune Up Your Generator: This guide provides a step-by-step approach to tuning up generators, including spark plug replacement and air filter inspection and cleaning. It’s a practical resource for hands-on maintenance tips. Explore detailed maintenance tips on Generatorist

- Cummins Inc. – Generator Scheduled Maintenance Procedures: This resource outlines scheduled maintenance checks and procedures recommended by Cummins for their generators, covering everything from the cooling system to electrical system checks. Learn more about scheduled maintenance from Cummins

- Shop Cummins – Generator Maintenance Parts: For those looking to purchase maintenance parts directly, this Cummins official online store lists all necessary components for maintaining Cummins generators, including filters and spark plugs. Visit Cummins Shop to view maintenance parts

- Cummins Inc. – Maintenance: Another helpful resource by Cummins that discusses the importance of periodic maintenance for optimal performance and long life of your generator, also detailing their planned maintenance programs. Check out maintenance insights from Cummins