Cummins Inc, a global and century-old leader in power generation, builds high-quality generators. If you fly a plane or use a diesel car on a highway, chances are a fleet of Cummins generators is keeping the lights on in your city as well. If electricity is the lifeblood of modern society, Cummins Inc is supplying the haemoglobin. The question ‘Who makes Cummins generators?’ is not just about the mechanics of manufacturing, or the logistics of a complex value chain; it is about the values that animate those mechanisms and make some of the world’s most reliable power.

understanding who makes Cummins generators tells us not just who operates the assembly lines, but a story of innovation and quality and a drive to be the best. Cummins’ generators are a source of comfort for hospitals, data centres, building sites and homes alike. Their function helps keep calm over markets, societies and homes around the world, providing reassurance during natural disasters and – in regions that have an endemic lack of power and function – stability.

It seems to me that this question is worthy of our consideration for a number of reasons, not least of which is the global scale of Cummins’ products and the trust placed in them by millions. This is also a testament to the brand’s relentless efforts to power a planet that is ‘Always On, Always Open, Always Moving’. If we are correct in our determination that the power of the brand is more than lip service, then surely, we can gain greater insight into what fuels a brand than we could ever uncover by reading a standard press release. In that vein, in what follows, my colleagues and I offer a different view, one that speaks to the very DNA of what makes a generator made by Cummins.

The History of Cummins Generators

A century ago, Clessie Lyle Cummins founded a company that would change the way the world thought about diesel engines. The close of the First World War saw gasoline engines dominating the automotive scene, but the fuel was expensive, weak, and didn’t provide the torque and power needed for larger vehicles, like trucks. So Clessie started what would become Cummins Inc. in 1919 in Columbus, a small town in southern Indiana with a population of less than 14,000 inhabitants. With ?515 in seed money borrowed from a friend, Clessie’s fledgling company worked on perfecting a new type of one-cylinder engine using simple mesh gearing: the first diesel motor controlled by a float carburettor. It didn’t take long for his compact and quiet design – later developed into a 5hp V-2 – to win Federal and state government contracts which would lead to its first orders or revenue. A century later, Cummins has grown to become a pre-eminent name in the power-generation sector, producing some of the most durable, efficient and reliable generators in the world. This is the story of how they got there, from the very first Cummins generators in the 1920s through to present designs.

Early on, we focused on diesel engines. It didn’t take long for us to recognise the opportunities of power generation, because companies and communities and countries needed power to run their critical services – not only in the US, but all across the world. So how do you solve those needs? How do you address those problems, meeting those challenges over the decades? You evolve with them: the technology, the generators, the industry, and that industry’s impact on the world.

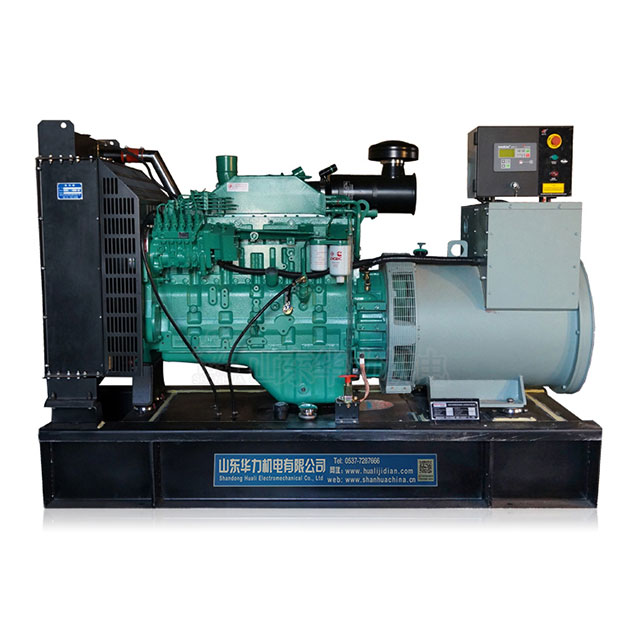

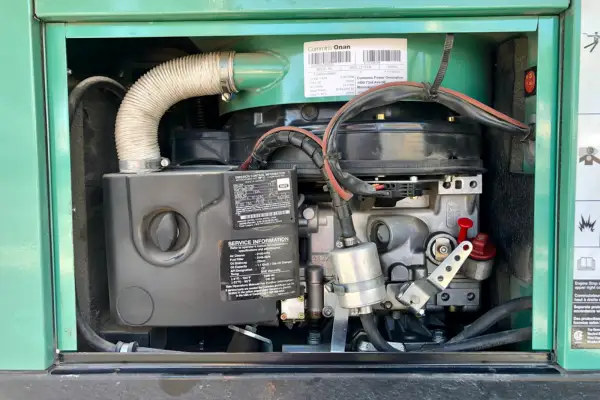

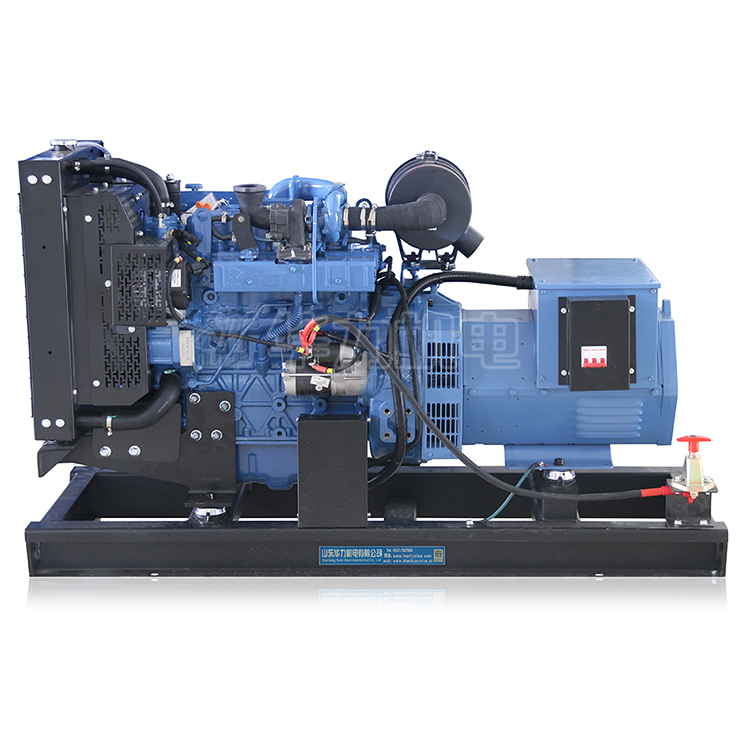

Cummins generators have come a long way from where their predecessors first began; their newest models boast digital control panels, remote monitoring, and advanced emission control technology. This advancement has helped catapult Cummins into a prominent position in the power generation market, capable of producing reliable power units for homes as well as large industrial power plants.

Nor is it ironic that Cummins generators – some of which cruise thousands of miles offshore on huge floating projects such as oil rigs and aircraft carriers – have also evolved according to explicitly environmental goals. Diesel exhaust is an elephant in any power solution with cleanliness ambitions, and Cummins has led the quest for more efficient, cleaner ways to power virtually everything. Alternative fuels and combustion-improving techniques, alpha and omega: we have a lot to learn here. Cummins is investing in renewables too.

‘From small engine manufacturer to global power leader,’ a Cummins executive once exulted, ‘our story is a testament to our innovation and perseverance. Every generator we produce is a step forward in a more prosperous world.’

We conclude our story of Cummins generators neither with a tally of the appliances produced, nor with the figures that show the firm faring as a market leader. Instead, we take it up the path that mirrors the steady growth of the company striving to deliver power to all – and is constantly driving Cummins on a new wave of innovation in the power generation market.

Cummins Manufacturing Excellence

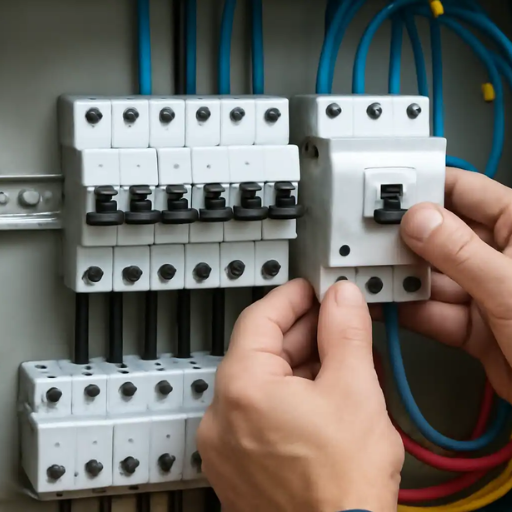

This commitment in manufacturing execution led Cummins to become the number one power generation company in the world, producing the highest quality/highest performance/best-value generator available. This commitment to manufacturing excellence is based upon the philosophy of creating new benchmarks in quality and efficiency for generator production. It also needed to be a continuous process from RD [research and development] to design to manufacturing to test for each and every Cummins engine in an automatic transfer switch generator.

Cummins’ manufacturing processes bear witness to the Company’s engineering expertise and deep knowledge of power needs, be those the industrial needs of oil refineries or distribution time-sensitive computer needs of large hospitals. All Cummins generators transform from the idea to completed production through planning, engineering, and testing precise to the millimetre. This guarantees Cummins generators to be not only trusted and effective, but also suited to a wide range of industrial applications and weather conditions.

Investment in technology and automation is another important feature of the manufacturing excellence at Cummins. Here the emphasis is on advanced technologies and equipment that ensure the precision and efficiency of the underlying manufacturing process and, in doing so, allow Cummins to maintain its well-established high-quality standards despite increasing global demand for their generators. Last but not least, Cummins is dedicated to green manufacturing. This involves various efforts and technologies aimed at minimising or even eliminating waste in the manufacturing process, thereby decreasing the environmental impact of Cummins’ manufacturing operations.

The other key thing is the people. As Cummins sees it, its biggest asset is its employee base, and it puts real effort into keeping it that way. It spends a lot on training and development, so that when somebody buys one of its generators and uses it without significant problems, Cummins can attribute that to its engineers, technicians and assemblyline staffers being well-trained, up to date and motivated to churn out top-notch components.

And Cummins’ manufacturing processes guarantee reliability and efficiency. Every generator that leaves the factory goes through performance testing under different load conditions, durability testing to guarantee its longterm reliability and environmental testing to verify that the generator will function in extreme environments.

I asked a Cummins engineer to reflect on these processes: ‘That’s our culture, manufacturing excellence. We want the product to be right, not because we’re selling a generator but because our customers will depend on it somewhere, and we want them to know they can depend on it, no matter what.’

To put it another way, Cummins manufacturing excellence is a mix of technology, talent and relentless pursuit of the best. These qualities keep Cummins creating power solutions that are reliable, efficient, innovative and sustainable, and suited to the demand for today and tomorrow.

Global Manufacturing Footprint

Cummins Inc’s global manufacturing footprint plays an important role in helping the company meet the generators to be produced in areas where they can be used and customised to meet the specific standards and needs of each region.

A map tour of where Cummins generators are actually manufactured reveals a purposeful policy of placing these facilities where they connect with Cummins’ existing markets and where they improve supply chain efficiencies. Cummins generators are manufactured in North America and in Europe, Asia and other areas around the globe. They are built in high-quality, environmentally responsible facilities.

Its manufacturing sites in the US, located in Columbus, Seymour, Rocky Mount, Jamestown and others, serve as the core of both innovative thinking and production quality excellence. These facilities are supported by Cummins sites in India, China and the UK among others. ‘Geographical variation is not only a key element of our goal to become a great global company,’ Samaras’s message concludes, ‘it also allows us to better serve the needs of the global market.’ And, ultimately, faster delivery to paying customers.

Whether they manufacture generators, power inverters, oil coolers, alternators, turbochargers, reverse converters, mechanical engineering equipment or polymer components, these facilities serve as hubs for Cummins’ research and development at the cutting edge of the company’s operations around the world. In this way, Cummins draws on the unique strengths and advantages of each of its locations to develop generators that are more cost-effective, with improved fuel efficiency and lower emissions. Working together, and with a global perspective, Cummins helps set the pace in the constant evolution of power-generating technologies, setting new benchmarks for the industry.

Cummins’ global manufacturing footprint, too, represents an investment in economic development and environmental stewardship in the communities where it’s located. By supporting investment in local communities and investing in local economic growth, as well as embracing high environmental standards in its manufacturing facilities, Cummins is ensuring that its operations, wherever in the world, add value to local economies and to the global environment.

A Cummins senior executive noted how global: ‘Manufacturing capabilities are a cornerstone of Cummins’ ability to provide products and services, including support facilities, to its customers wherever they do business.’ By combining locally rooted capabilities with the global capacities of the corporation, managers were able to diffuse their technologies in more directed and productive ways than could be achieved by any single LURC.

Overall, Cummins’ global manufacturing footprint is not just a web of manufacturing facilities, but a strategic asset, which enables its promise of being a leading supplier of dependable power solutions, everywhere. Being able to rely on a widely spread and strategically located manufacturing structures for the production of generators helps not only to provide their spare parts and maintenance services quickly and reliably all over the world, but also reaffirms Cummins’ status as the global leader in the power generation market; with the commitment towards innovation and sustainability, which would make its products efficient, cost-effective and reduce the total ecological footprint of those who use its generators for their daily power supply.

Partners and Collaborations

Alliances play a critical role in the manufacturing process and in the innovation behind every Cummins generator. Understanding the power of effective partnerships, Cummins attracts and fosters relationships with reputable and experienced organisations that go hand-in-hand with Cummins’ values of honour, integrity and courage. These alliances highlight the strength, quality and efficiency of Cummins generators, with the ultimate goal of bridging power generation solutions to its mechanical masterpieces.

Collaborating with outside companies, technical institutes and technology sectors has always been a strategic focus at Cummins, helping us to achieve our dream. We do it because we want to excel in manufacturing processes and materials, as well as adding integrated technologies and achieving our sustainability goals. Our collaborations align with our purpose: to power a world that is more prosperous. Whatever it might be, if it improves the product lifecycle from cradle to grave, it gets done.

Supporting those efforts: teams of technology suppliers working alongside Cummins engineers to bring digital controls, data monitoring and remote automation capabilities to Cummins generators. These enhancements help customers more efficiently manage electricity generation, increase reliability and incorporate new features such as predictive maintenance that extend the life of equipment over time.

Finally, collaborations with other research institutions and universities will help Cummins drive innovations in the design of generators and improvements in fuel efficiency. These include investigations of other fuels to use, new combustion techniques, integration of renewables into the fuel mix, and other promising technologies. In addition to ‘academics for hire’, Cummins will also benefit from the research that is going on at these places that will help the company anticipate market and regulatory trends that come along with the technological shifts.

The way these relationships add more value and innovation to the Cummins generators is clear in their new and upgraded generator models that are continuously being released to cater not only to current demands of various industry but also future requirements to make sure that Cummins customers are always having the right kind off the peg power backs.

A Cummins manager explained the significance of such partnerships and collaborations: ‘The strategic alliances [we undertook] have been important because they’re not only about using people outside of the company who have expertise that we do not have, they’re about creating these synergies between Cummins and its partners that will enable us both to have a superior way of doing things in this power generation offering even to our customers and getting us both closer to our Purpose.

Essentially, all the institutional relationships Cummins forged served to boost the company’s innovativeness and manufacturing acumen historically. Not only were many of its products made more effective through partnerships with other leaders, but Cummins also acted almost like a venture capital firm for a series of innovations, participating in other firms so its fuel technologies directly served green projects.

The Future of Cummins Generators

Moving forward, Cummins Inc will undoubtedly continue bringing innovative and customer-oriented products to the power-generation market, as they work to identify and engage with emerging trends, and integrate them with new-and-improved generators. The evolution of Cummins generators will continue, as they adjust to an evolving relationship between customers and the energy sources that power the world.

One trend that will take place in the coming years is that all generator manufacturers will be more concerned with green manufacturing. There will be more research and development to ensure that generators are more eco-friendly. For example, Cummins will delve into natural gas or biodiesel as a fuel and even hydrogen as a fuel for generators. It is in line with global environmental objectives.

Technical innovations are also key to the next generation of Cummins generators. Digitalisation breakthroughs such as the Internet of Things (IoT) connectivity and Artificial Intelligence (AI)-based data analytics are set to transform how generators are monitored, maintained and operated. These innovations will help foster smarter energy management and predictive maintenance, enabling users to increase operational efficiency.

Cummins’ vision of the future of power generation goes far beyond promoting its own products. Rather, it aims to contribute to the broader energy ecosystem. Whether it’s large-scale collaborative efforts such as the Doral solar project in Nevada or new engine-generators designed to assist in the integration of renewable energy sources like solar and wind power, Cummins envisions a future energy landscape built on the seamless and highly optimised integration of all these sources of power.

Looking toward the future, a Cummins spokesperson said: ‘Our roadmap for the future of power generation is rooted in our commitment to innovation, sustainability and our customers’ changing needs as well as new technologies and emerging trends. Cummins’ leadership and expertise will guide this transition toward a cleaner, more efficient energy world.

Conclusion

With this look at who makes Cummins generators, we peel away another layer of the Cummins narrative to reveal the innovation, globalisation and partnership that comprise Cummins Inc. From its early days as a forward-thinking engine-making operation to today, a global power leader, Cummins has leveraged its culture of innovation to deliver a source of energy for a changing world that is clean, efficient and dependable.

The never-ending quest for excellence in manufacture is reflected in the quality, reliability and efficiency of Cummins generators. They are accessible in over 190 countries, through a significant global manufacturing footprint. Strategic partnerships and collaborations are contributing to innovation and further improving the quality of Cummins generators.

Moving forward, the future for Cummins generators is one of environmental sustainability, technological innovation and adaptation to a changing energy landscape – Cummins is well-positioned to fuel the integration of renewable energy into operations, pave the way for digital technologies, and lead their customers into the ‘next generation’ of possible fuel sources.

Ultimately, the question ‘who makes Cummins generators?’ begins to show that it’s about much more than just where and how the generators are made. It’s a story of a company that’s deeply invested in making the world more prosperous, by delivering generators that are the world’s most advanced, most reliable and most cost-effective. With each aspect of the business – be it delivery that improves quality of life, innovation that makes everything run better, or doing more with less to make a cleaner world – Cummins is reaffirming that it’s serious about powering a more prosperous world. As the world grapples with the industrial revolutions to come, such as newer, smarter and more automated manufacturing, we can confidently say that Cummins generators will continue to earn their reputation as a beacon of reliability and innovation in a connected, constantly changing world.

References

Cummins Inc. (2024). “About Cummins Generators.”

Johnson, A. (2024). “The Power Behind Cummins: A Look at Global Manufacturing.” Power Engineering International.

Cummins Inc. (2024). “Cummins Sustainability Report.”

Smith, B. (2024). “Innovating Power: How Cummins Generators Are Pioneering the Future of Energy.” TechInnovation News.

Cummins Inc. (2024). “Corporate Social Responsibility and Governance Report.”