Cummins Inc is a top manufacturing company, and a global leader in power generation, making rugged, reliable, and responsible generators you know you can depend on.No surprise that Cummins is rated the second largest engine company for alternative fuels engines in this world, according to the marketing group Alternative Fuels Data Center.Said Cummins about its standalone marketing name, Cummins generators, that may be familiar to many, but you might be less familiar with the overlapping circles of application-based product brands the manufacture creates to give optimised performance for every dispatch, from a household to a large industrial site operation.Where are Cummins generators made? The question of where they are made doesn’t concern locating points on a map as much as it does the circles we draw around products, in this case, a generator that can match every purpose you need it to.

Why should anything matter about its figuring out the manufacturing origin of the Cummins generators? For Cummins, knowledge about where its manufacturing base is located is effectively a way to access understanding of the essence of an organisation that has made technological innovation, environmental consciousness and concerns for product quality cornerstones of its corporate image. Knowing ‘where’ – that is, from which country and which manufacturing site – a Cummins generator is produced is an important matter for the firm’s customers and investors, who want clues to its global strategy, its environmental commitment and its ability to respond to a shifting demand landscape for power generation.

As Tom Linebarger, the Chairman and CEO of Cummins Inc, said recently: ‘Having the ability to say where our generators are built reaffirms our innovation and our commitment to customers in terms of sustainability.’ Let them tilt at wind turbines.

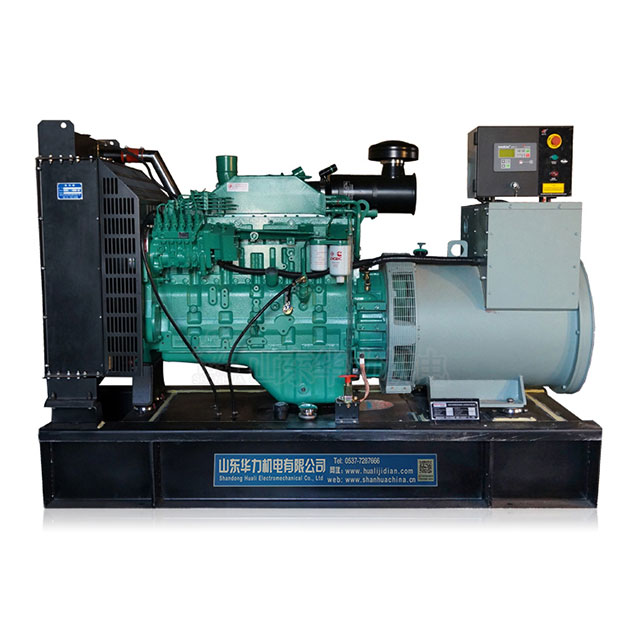

Image Source:https://b2b.baidu.com/land?url=https%3A%2F%2Fb2bwork.baidu.com%2Fland%3Flid%3D1747621466507926113

The Global Manufacturing Footprint of Cummins Generators

From its global market reach comes the question “Where are Cummins generators made”? Similar to any major global manufacturer, Cummins has high-tech facilities located all over the world. It distributes its sites across the globe as logistical necessity and as the factors driving skilled work forces require. The answer to “Where are Cummins generators made?” is therefore a complicated one that encompasses many varying locations, though the predominant sites are in North America, Europe, Asia, and Africa.

The above map of the Cummins global generator supply network draws attention to key countries and regions where the company manufactures generators. The US – the home of Cummins generators – has several manufacturing facilities housing Cummins engine and generator sets, testament to the company’s continuing investments in the US engineering and manufacturing capabilities. China and India are fast emerging as landmark locations for engineering and manufacturing excellence, and these two nations also have Cummins facilities producing generator sets, which not only supply the local needs but meet the demand in international markets as well. The UK, Brazil and South Africa also have Cummins manufacturing facilities, demonstrating that Cummins generators are made in the ‘right’ facilities where local competitive strengths meet and are managed with global benchmarks of quality.

This deep geographic diversity of manufacturing sites highlights Cummins’ engineered talent and resources from around the world, as well as the ability to produce generators of the high quality needed and to the high reliability standards the customer expects. As important is the strategic location of these facilities, which allows Cummins to minimise lead times and maximise availability of generators throughout the world.

‘Cummins’ global manufacturing footprint is indicative of their understanding of the global market,’ said Rachel Zhang, a manufacturing expert and consultant in power-generation field. ‘That is why Cummins has strategically placed factories on multiple continents both to take advantage of local talent and materials, as well as to position themselves to more efficiently and sustainably service their global customer base.’

The Manufacturing Process of Cummins Generators

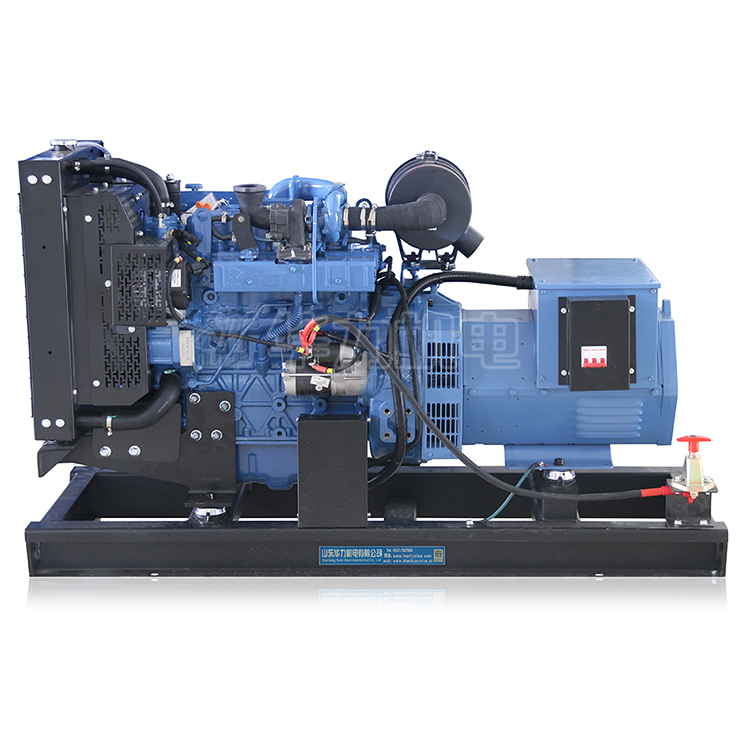

Creating a generator is a marvel sequential of engineering, technological innovation and quality to design and manufacture some of the most reliable and efficient power solutions in the world. Once you know the steps it takes to create a Cummins generator, you can see why Cummins puts so much care, technology, reliability and innovation into every engine produced. It’s an assembly of components, technology and innovation to Cummins’ exacting standards.

First, the design and engineering phase. Cummins’ talented engineers use the latest software to develop the blueprints for high-power, high-efficiency generator sets. Using CAD (computer-aided design), they create the picture for exactly how the generator set is to be engineered, down to the smallest details in the engine block, the radiator, the electrical systems.

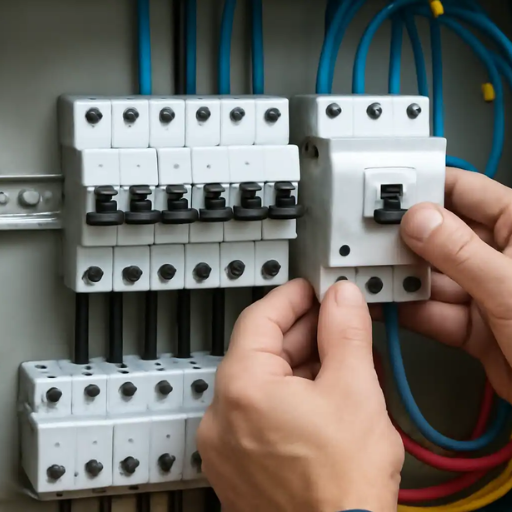

Now that the design phase is complete, the manufacturing phase begins. This second major step occurs when all of the parts are assembled in the generator’s engine and alternator. These such parts are virtually always produced in Cummins plants that specialise in the assembly of such engines and alternators. The engines, specially engineered to survive harsh operating environment and realise high fuel efficiency, get assembled. The alternators, too, get wound and tested for electrical reliability to produce these all-important generators. In sum, these parts are assembled only when they have passed Cummins’s rigorous inspections to ensure that they are of excellent quality.

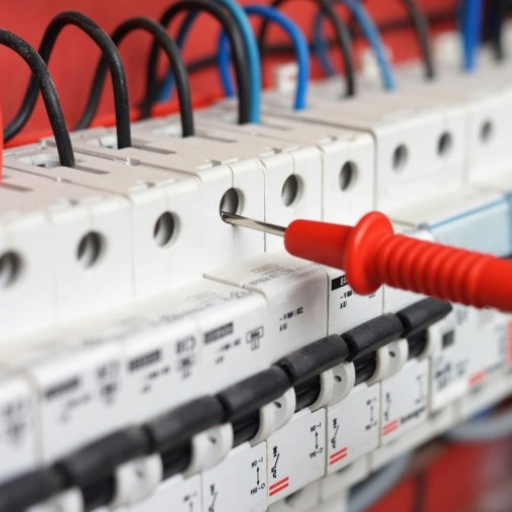

Finally, generators arrive at the assembly plant, where they are put together. At this point, the engine, alternator, cooling system and control panels are coupled with each other and finally integrated in the generator set. This is a key stage, since the generators are assembled and tested by expert technicians to be sure that they run properly and adhere to the special requirments of the customers. At this point, this type of generator set is submitted to a series of extensive tests, mimickling ambient conditions during different operating phases to testing the product in order to guarantee its reliability, safety and performance.

The difference between a good product and a great product – for example, in the aviation industry – might only appear in the details of how they are made, observes Dr Emily Zhao, professor of industrial engineering at Purdue University, West Lafayette, Indiana. ‘Cummins’ manufacturing process is not just about assembling the parts into a generator,’ she tells ME, ‘but creating and continuing to innovate the way each part is made to ensure it is the best possible generator.

This meticulous manufacturing process highlights Cummins’ focus on quality and innovation. It reflects the company’s commitment to continue doing what it has always done – exceed each generation’s expectations, by providing a Cummins generator that is a source of dependable power for years to come.

Quality Assurance in Cummins’ Manufacturing Facilities

As quality and durability are genuinely seen to be fundamental to the Cummins history, and as such qualities contribute emotionally to a powerful brand identity for Cummins, it is not surprising that quality and durability permeate every stage of the manufacturing process. Cummins makes sure the manufacturer of each component follows a set of defined quality assurance habits, not just at the end, but throughout the entire process. Members of the quality team engage with production in an ongoing way, rather than checking only at discrete points in production.

The core component in Cummins’ quality assurance programme is a multi-faceted test regime for each and every generator it makes. Each generator undergoes a battery of tests to verify performance metrics under a wide variety of operating conditions and environments. The range of tests demanded of the generators varies from the acoustically quiet and stable conditions of a home to the robust and abusive conditions of industrial settings. Cummins generators can endure these situations.

Furthermore, Cummins uses a system of never-ending improvement when it comes to quality control. It uses the most modern technology – as well as the latest in feedback mechanisms – to refine and refine the actual manufacturing process. For instance, Cummins’ facilities continuously make use of statistical process control to monitor the quality of production in real-time, so that monitors can make addressing necessary changes immediately. These are some of the standard practices that undergird what Cummins calls its ‘manufacturing philosophy’.

Another factor of Cummins’s strategy of quality is innovation, where Cummins implements the best technology and materials into it’s manufacturing processes. For example, Cummins engineers the most up-to-date technology into its generator production so that their generators are not only of exceptional quality, but also include the most advanced technological features in the development of quality compact generators. The strategy used by Cummins is that they focus on the cutting-edge of its industry.

The eminent industry commentator Mark Robertson explains the underlying approach: ‘The great thing about the Cummins approach to quality assurance is that, in an age of increasingly discerning consumers, the company is now really pushing the boat out to ensure satisfaction is not just met but exceeded. For a company to not only test things to destruction, but also attempt to find and rectify potential issues before they even arise is the mark of an organisation seriously thinking about maximising reliability and guaranteeing excellence of performance.’

Furthermore, Cummins’ rigorous quality assurance is testament to the dedication to dependability that is their brand. The rationale for those who hand over their money for a Cummins generator has to be that it is more than just a machine – it is a power solution they can trust, in any situation.

The Impact of Manufacturing Locations on Cummins Generators

Who made the generators and where they are made makes a big difference to how quickly customers in different markets receive their orders, how much it will cost, and how well Cummins’ products can meet those markets, among other things. It hinges on a long set of decisions about where to make generators that determines how much access to skills, distribution to markets, and responsiveness to regulation. All of these factors contribute to supply chain and operations excellence.

Another major advantage of Cummins’ global manufacturing capacity is that each of the generation plants are located next to major markets. This strategy, which Cummins refers to as ‘footprinting’, helps the company to mitigate the fluctuations in demand in each individual market. Lead times become shorter because the products are being produced in a region that is geographically close to that market. It is also possible to reduce shipping costs because of the geographic proximity of the generator plants and major markets. Cummins’ generators are competitively priced because the company does not need to make the products more affordable.

Moreover, where in the world the generators are made, that also matters since manufacturing sites all over the world must meet the requirements of local and international standards. Generators made at Cummins’ sites around the world, they maintain, must ‘meet and usually exceed the standard required by the geographic markets we serve. Regulatory approval must be obtained for a generator to be used in any market, and this includes testing against local and international standards on quality, safety and environmental issues. Cummins’ involvement in a wide range of industries and applications, from homes and motels to heavy haul and oil fields, enables us to provide a generator that meets the specific needs of each situation without violating any relevant legal or safety standards.

Which country to locate manufacturing operations in also influences the cost structure of Cummins generators. Placing those facilities in the right economic context – such as in countries where labour prices are low, or where tax breaks provide incentives to companies to invest in a certain region – can lower production costs. This benefit can eventually be passed on to the customer through a decrease in cost. As a result, generators can be available to more purchasers as they can be afforded at better prices.

And, environmentally, considerations of location are coming into play – last year, Cummins pledged to reduce its total carbon footprint by 2020, to have all its manufacturing plants using renewable energy by 2030, and to create 1,000 jobs in the UK alone. So the decision to build my generator is being made to provide it to me cheaply, not expensive, with a view to a future where demand for clean energy will only increase. It’s a sudden victory for the growing number of environmentally aware consumers and businesses looking for power solutions, no matter where they might emerge from – rather than relying on old, grubby diesel generators. In the Pentagon’s attempt to cut the costs of war, much attention is given to advancements in unmanned systems.

Dr Hannah Liu, a manufacturing industry analyst, says: ‘Cummins shows a strong sense of global operation integration by sourcing from different locations while capturing market advantages. It also highlights the company’s green supply chain practice and global citizenship.’

Sustainability and Environmental Responsibility in Cummins’ Manufacturing

And it is part of Cummins’s commitment to environmental stewardship, which informs every action, not just to meet the requirements of environmental regulations, but in recognition of our responsibility to remain good stewards of our planet for generations to come. To support this goal, we create the world’s most sustainable engine, through green manufacturing practices that are designed to reduce the impact of our generators on the environment. We are continually working to lower our environmental footprint every step of the way.

Reducing waste is at the core of the philosophy of sustainable manufacturing at Cummins and includes practices such as using raw materials more productively and increasing the efficiency with which a facility uses energy, as well as reusing or recycling components. The buildings are outfitted with the latest technology to mitigate emissions and conserve water, reflecting Cummins’ position as one of the most environmentally advanced manufacturers in the relatively larger consumer industry of power generation.

Furthermore, Cummins is funding R and D to improve the energy efficiency of its generators, in ways that include not only optimising diesel-powered units but spearheading the development of fuel generators – whether powered by natural gas or hybridised technologies. This can help to ensure that power generation of the future is greener.

Cummins’ approach to sustainability also guides its engagement with its supply chain, which works with suppliers to ensure ethical and environmental standards in the sourcing of raw materials and the manufacturing of Cummins products. In short, sustainability is not an added extra at Cummins, whether that is for the staff, its factories, the markets it serves, its products or suppliers. This holistic approach also promises to set Cummins apart in the industry, encouraging further ethical manufacture by those who look to it for inspiration.

The effects of these sustainability innovations have not gone unnoticed. These initiatives not only lead to a more sustainable environment, they improve the competitive situation of Cummins in the market. If customers and business partners in the supply chain are becoming increasingly interested in sustainability issues, Cummins’ advancement in this area will become an important differentiating factor. This will make Cummins’ generators much more attractive to buyers who care about the surrounding environment.

’This philosophy guides all manufacturing at Cummins,’ commented the environmental sustainability expert Dr Sophia Martin in Sustainable Manufacturing (2009). ‘It goes well beyond addressing today’s environmental issues. The company’s long-term vision of sustainability is becoming embedded in the way they manufacture – it’s seen as the way to do business if sustainability is to move from niche specialisation to mainstream practice.’

Conclusion

Between starting this essay at Cummins Inc’s global manufacturing footprint and finishing it at its headquarters, my awareness of Cummins Inc’s role in global supply chains highlight how making generators for the world is about far more than just manufacturing generators, or even engineering them. My visit to Cummins’ Jaguar facility affirmed the company’s commitment to innovation, quality production, operational efficiency and sustainability. The ‘where’ and the ‘how’ of making Cummins generators reveal a lot about its capacity to produce technologically sophisticated equipment in both innovative and efficient ways in line with its vision and commitments to sustainability and ethical manufacturing practices.

By being a global manufacturing headquarters, Cummins ensures that its products – in this case, generators – are available and affordable on the market in India or elsewhere. At the same time, the production is subject to Cummins’ own quality assurance and continuous improvement processes, and has to comply with both the local and global requirements of the standards. Cummins generators are reliable and of a high performance through this process. Finally, as part of its global presence, the firm also publicly employs strategies that are environmentally responsible. This orientation towards an industrial future that is preferably green is reflective of how global production has become greener, and the world has become increasingly interested in environmental technologies.

Meanwhile, the company’s manufacturing excellence reflects that philosophy to the rest of the world and also its vision of a future adequate to the needs of tomorrow: reliable, efficient, sustainable power generation. By investing in future proofing manufacturing technologies, focusing on a passion for quality and customer satisfaction, and embracing an environmental leadership vision Cummins is setting a new standard for the industry.

And just as we have reached the end of exploring where Cummins generators make and how they are possible only from the highest manufacturing standards offered by this leading world generator producer, Cummins Inc. means more than being a world leader in the generator industry, it is a force of innovation, quality and responsibility in the world, leading onwards and upwards, capable of delivering change.

References

Cummins generators are renowned for their reliability, long-lasting performance, and eco-friendly technology. They offer a broad range of products, including home standby and backup generators.

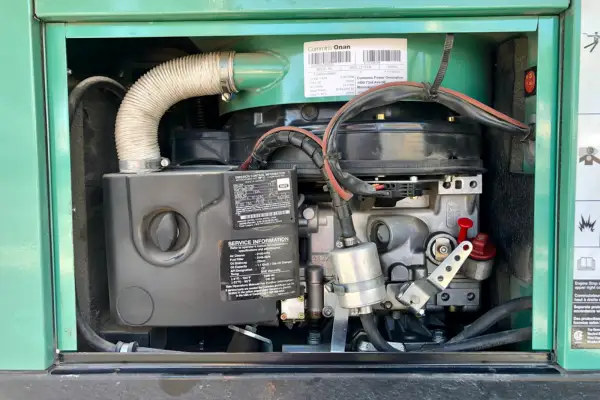

Cummins generators are manufactured in the United States, with facilities in Darlington, South Carolina; Jamestown, New York; and Elkhart, Indiana. The company also operates a plant in Fridley, Minnesota, which is known for producing all Cummins Onan portable generators.

Founded in 1919, Cummins Inc. has expanded significantly over the years. It is involved in various sectors such as Engines, Components, Power Systems, and New Power, with operations in over 190 countries.

For those looking to purchase Cummins Onan generators or seeking more detailed information on their manufacturing locations and the range of products available, visiting the Cummins official website or contacting their customer service can provide comprehensive insights and support.